Innovative News | Improved Desk Thermal Evaporator-DTT

Enhanced Uniformity of Thin Film Deposition in Thermal Deposition Process via Extended Deposition Chamber

Thermal evaporation deposition is one of the Physical Vapor Deposition (PVD) methods. In this method, the target material is placed inside thermal sources. These thermal sources are normally in form of Boat, Basket or Coil. The materials to be deposited are heated up, melted and evaporated by passing a high electric current through the terminal of evaporation sources. The vapor generated from the target material moves to the substrate and is deposited as a thin film with a thickness of a few nanometers to a few micrometers.

Boats or baskets are made of refractory metals such as tungsten, molybdenum or tantalum. Thermal evaporation deposition method is also called resistive evaporation. Standard distance between the substrate and the evaporation sources depends on the dimensions of the substrate. The larger the substrate size, the greater the distance from the evaporation source is needed to create better thickness uniformity. If the dimensions of the substrate are large enough that the entire surface of the substrate is not covered during the coating at the standard distance between the substrate and the evaporation sources, the substrate area covered can be increased by increasing this distance.

Deposition rates decreases with increase of distance between substrate and evaporation sources, but improves uniformity of deposited thin film. This also depends on level of vacuum in the chamber.

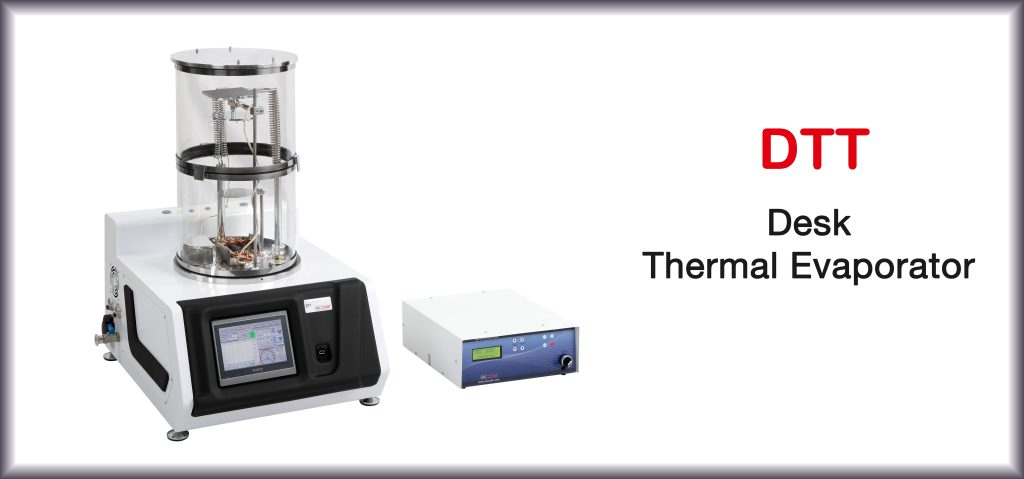

Improved Desk Thermal Evaporator-DTT

In the thermal evaporation system manufactured by Vac Coat Ltd., this distance is usually 20 to 25 cm. In order to produce a uniform thin film deposition on larger substrates, Vac Coat Ltd. has designed and added a new feature to its present DTT model thermal evaporation deposition system. The new version allows the user to increase the distance between the substrate to the evaporation sources up to 50 cm by installation of a second chamber.

For further information, please visit our website.

Improved Desk Thermal Evaporator-DTT

In the thermal evaporation system manufactured by Vac Coat Ltd., this distance is usually 20 to 25 cm. In order to produce a uniform thin film deposition on larger substrates, Vac Coat Ltd. has designed and added a new feature to its present DTT model thermal evaporation deposition system. The new version allows the user to increase the distance between the substrate to the evaporation sources up to 50 cm by installation of a second chamber.

For further information, please visit our website.