What Are Vacuum Feedthroughs?

Feedthroughs in a vacuum chamber, enable different components, like electrical cables, cooling water hoses, or mechanical parts to pass through the device, without causing any leakage under high or ultra-high vacuum conditions. Vacuum feedthroughs are useful in various applications, especially where precise pressure control is required, such as thin film deposition systems.

Depending on its mission, various kinds of feedthroughs can be used in a vacuum system. Vac Coat vacuum coating systems are provided with special features, such as precise thickness measurement by QCM thickness sensors, sample stage rotation, argon or reactive gas injection into the coating chamber for ion sputtering, hence they are supplied with a variety of electrical, fluid, and mechanical manipulation feedthroughs to guarantee the stable vacuum environment inside the chamber.

Also, the Vac Coat pulsed laser deposition system (PLD-T) is supplied with viewport feedthroughs.

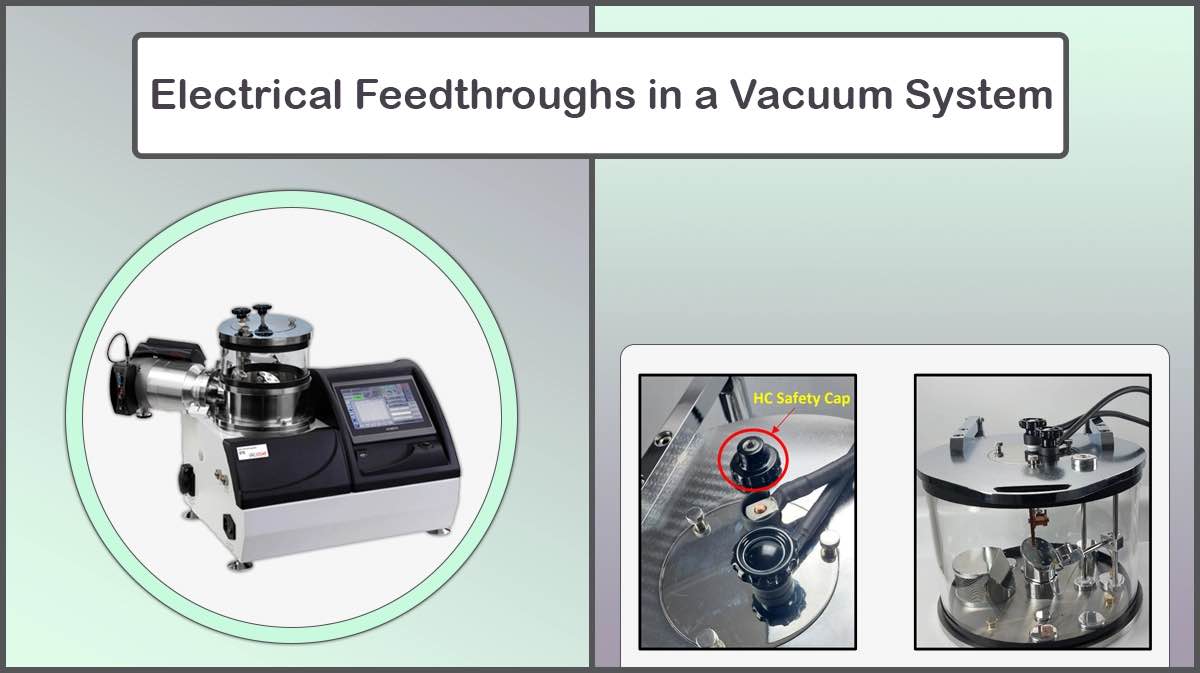

Electrical Feedthroughs

Electrical feedthroughs in a vacuum chamber allow the transmission of electrical signals and current between the inner and outer parts of the vacuum chamber.

Electrical feedthroughs include one or more conducting pins that make electrical connections through a well-sealed vacuum flange against air leakage. The conductive pins are electrically separated from the flange by ceramic insulators which can usually tolerate a significant pressure difference along their length.

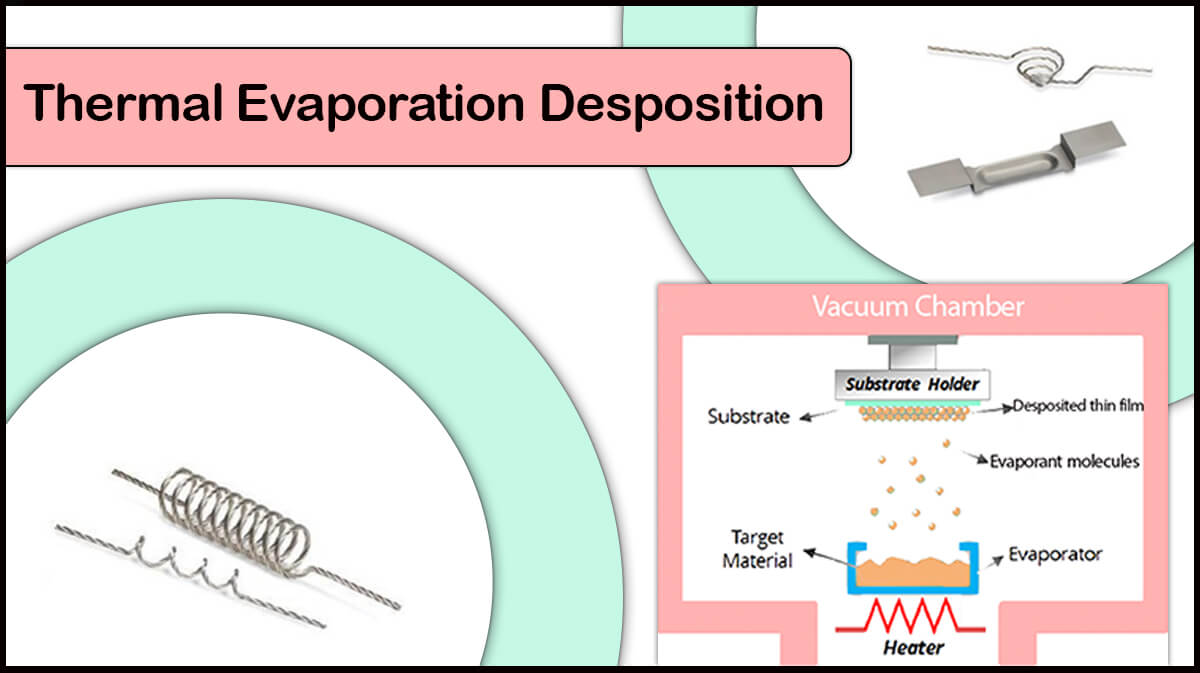

Vac Coat thermal evaporation deposition systems that are equipped with high-current feedthroughs on the chamber lid, like DTE, DSCT-T, and DCT-T-300, require high-current passing through the thermal source holder (boat, basket, or coil) reaching a maximum of 100 A. Vac Coat uses special safety caps for these connections (as shown in Figure 1) to ensure the safety of the users.

Temperature of the Electric Feedthrough in the Vacuum Coating System

Passing this high current can increase the temperature of the feedthroughs in a few minutes, damaging the elastomer seals, which leads to leakage in the vacuum system, and disrupts the process to reach the predicted ultimate pressure inside the vacuum chamber. So, these thermal evaporation systems are suitable for short-term deposition processes to prevent heating up and damaging the feedthroughs.

How to Overcome the Feedthrough Heating?

For more durable and multiple source thermal evaporation, Vac Coat offers DTT thermal evaporation deposition system, in which the high current electrical feedthroughs are installed on the chamber base to pass an electric current of about 100 A and water-cooled to prevent heating problems. Also, the water flow and the temperature of the high-current electric feedthroughs in these systems are checked and displayed on the monitor of the device continuously for safety precautions. Accordingly, if the temperature of the electrical feedthrough passes above the defined level, the power supply will be turned off automatically and the deposition process is stopped.

Moreover, Vac Coat produces hybrid coating systems that enable both sputtering and thermal evaporation deposition, like DST2-TG and DST3-T, equipped with water-cooled high-current feedthroughs. For more information about vacuum coating systems made by Vac Coat Ltd., refer to the company’s website and the catalogs of our products.