Sputter Coaters

Sputter coating as a common method for thin film deposition by vacuum plasma is used in various applications, such as fabrication of nano-electronic and optical devices, sensors, solar cells, as well as SEM sample preparation. Ion sputter coaters generate a sustainable plasma under controlled conditions to obtain a uniform coating. Magnetron desk sputter coaters produced by Vac Coat Ltd. are pioneers of automated low and high vacuum sputter coating machines for producing thin films of various materials by using DC/RF sputtering techniques.

Ion Sputter Coating Technique

Ion Sputtering is a method to deposit thin films of various materials on a substrate. Nowadays, ion sputter coating (Shortened as sputtering) is used in SEM Coaters for coating Scanning Electron Microscope (SEM) samples with a conductive thin film, called metallizing. This is an essential step in SEM sample preparation to reduce electric charging of the sample surface, diminishing heat damage to the sample, and achieving high-quality images. Also, sputtering is widely used in thin film deposition for numerous research applications in solar cell, battery, sensors, and micro/nano-electronics.

How Does A Ion Sputter Coater Work?

Sputter coating of a sample requires plasma formation of a process gas between two electrodes to sputter the atoms of a target material placed on the cathode, which are deposited on the substrate afterward. This process needs vacuuming and precise manipulation of the base and working pressure of the chamber, process gas flow, substrate bias voltage and temperature, cathode voltage, plasma current, and deposition time to obtain desired thickness and structure of the coated layer. These numerous parameters can be handled accurately by using an automated sputter coater machine with programmable coating processes through user-friendly software.

To meet the worldwide demands in advanced coating, Vac Coat offers high-precision sputter coaters with extensive operational options. Programmable deposition process, real-time monitoring of the chamber pressure, cathode temperatures, and coated layer thickness by Quartz-crystal microbalance (QCM) sensors, and many other innovative features have made Vac Coat magnetron sputter coaters among the pioneer coating devices. Vac Coat also designs tailor-made desktop sputter coaters that fulfills the customer requirements to provide a perfect ion sputter coater for special needs.

Main Features of Our Desk Sputter Coaters

The key features of Vac Coat sputtering systems include:

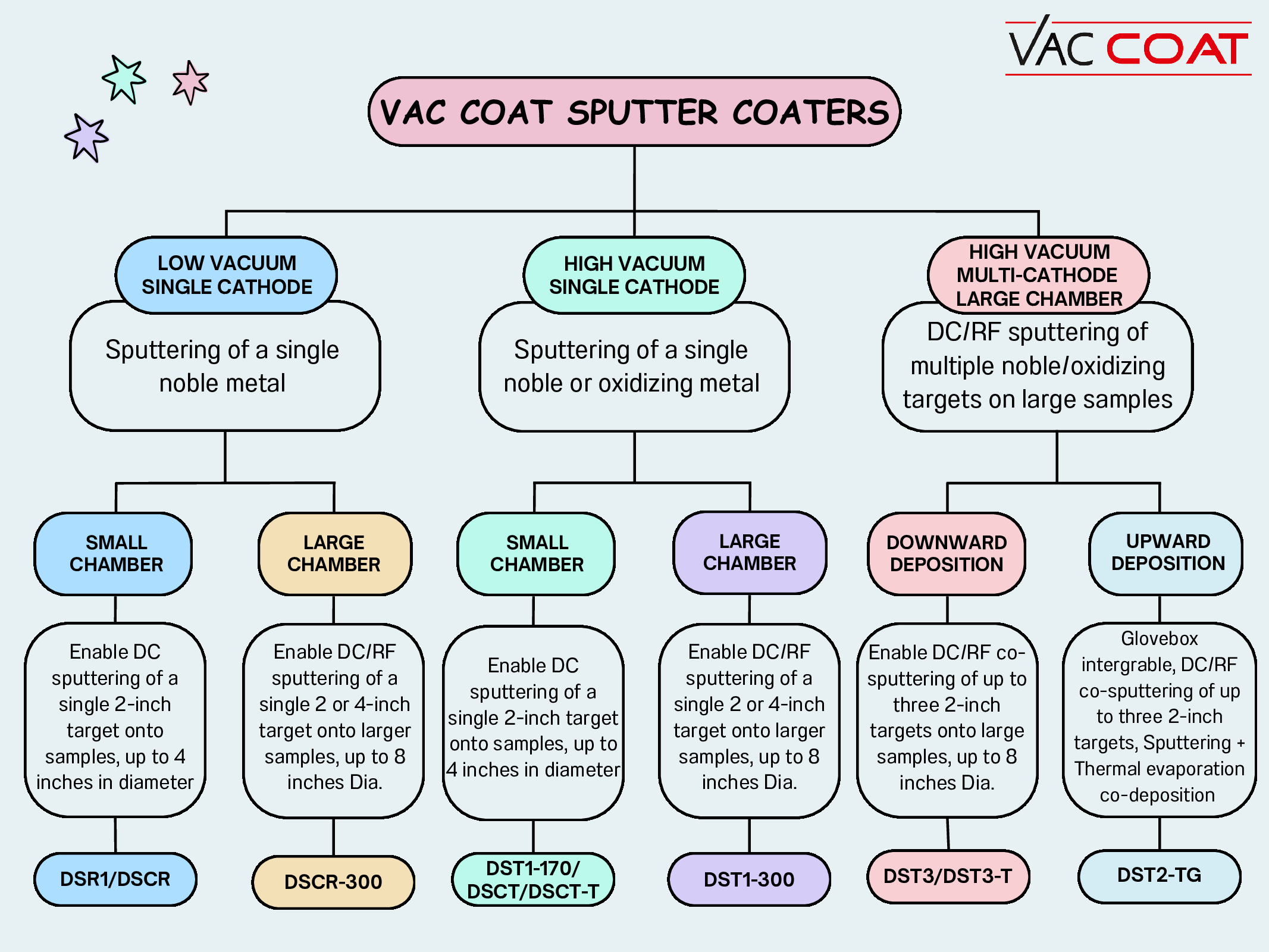

Vac Coat Sputter Coating Machines

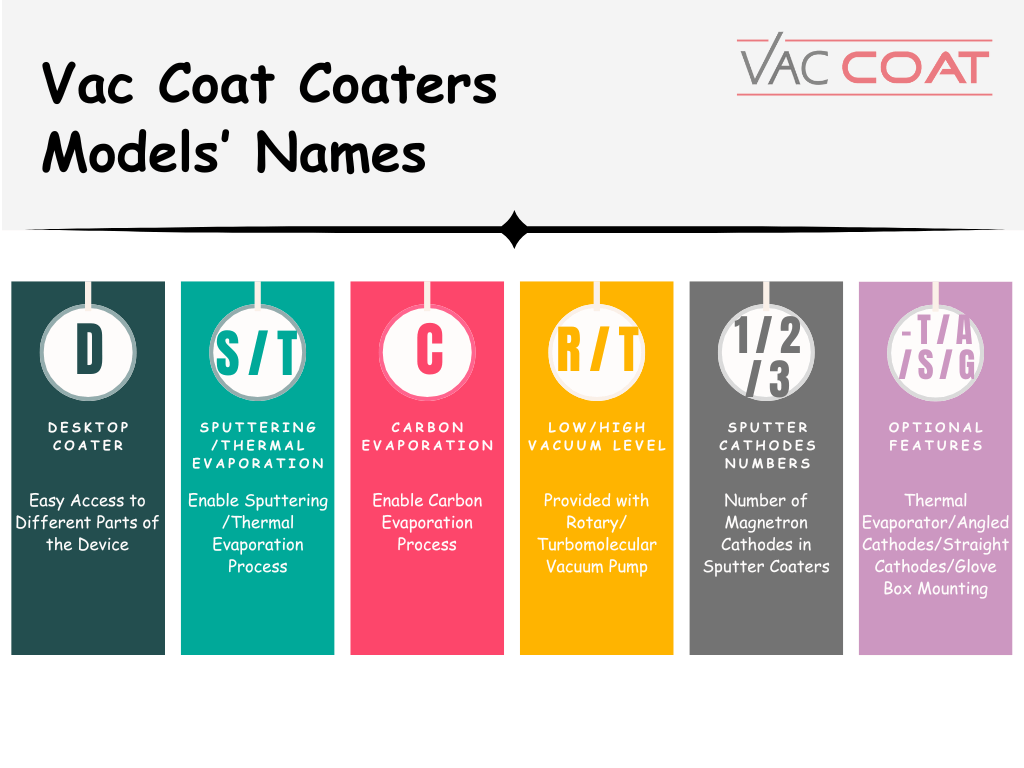

Vac Coat Ltd. is a renowned designer and manufacturer of desktop sputter coaters working at low or high vacuum. Vac Coat magnetron sputter coaters are provided in small chambers or large chambers, supplied with one cathode or triple cathodes and customizable features. So far, Vac Coat sputter coating machines are being used in a wide range of duties all over the world, from electron microscope sample preparation to the edge of science research projects.

2 Desktop Sputter Coaters

The rotary-pumped sputter coater DSR1 is favorable for low vacuum coating thin films of noble, non-oxidizing metals like gold (Au) and silver (Ag) and platinum (Pt), for conventional SEM imaging.

Magnetron Sputter Coaters with Carbon Coaters

Vac Coat sputter coaters can also be used as a carbon coater in a single compact desktop system with optional carbon fiber/rod evaporation attachment in low vacuum DSCR and high-vacuum DSCT coater models.

Consecutive layer coating and co-sputtering is made feasible with DST3 multi-cathode sputtering system, in two different cathode configurations, angled (DST3-A) and straight (DST3-S). These models are also offered with thermal evaporation option (DST3-TA and DST3-TS). Large samples uniform coating (up to 8 inches) is made possible with uniquely designed cathode masks in DST3-S model.

Glove box turbo-pumped multi-cathode sputter coater DST2-TG can be mounted inside a glove box, where purity is vital. This high-vacuum coating system can co-deposit materials through both sputtering and thermal evaporation methods, without breaking the vacuum.

The Other Our Sputter Coaters

FAQ

Does your device need to be installed by Vac Coat experts?

Setting up our system is very straightforward. We have also provided a clear user manual and instructional videos that help you to set up the system step by step. Remember that our after sales service are always available to help and answer your questions.

What is difference between the DSR1 and DST1?

The ultimate pressure in DST1 is very lower than DSR1 (5×10-6 Torr in DST1, compared to 5×10-2 Torr in DSR1). DST1 is able to sputter not only noble metals, but also oxidizing targets. The grain size of the deposited layers of metals like Cr and W are much finer than the deposited noble metals, thus more suitable for the field emission electron microscopes (FESEM).

What is the application of a planetary sample holder?

In the case of coating on porous samples, inside of the holes will not be coated well during the deposition and would be blind spots for an electron microscope. The planetary sample holder maximizes the coverage of the coating by rotating the specimen during the coating process.

Considering the high-quality device packaging, should I keep the device packaging box?

If the device needs calibration, maintenance or repair in the factory or our company’s representative workshops, it must be packed and transport in its original box.

How long do my consumables (Target, Ar gas, and quartz crystal) last?

It depends on how much they are used, for example, a gold target with a thickness of 0.15mm is sufficient for the coating of 300 to 400 electron microscopes samples, and a 5-liter Argon gas cylinder is enough for the coating of more than 2000 samples. For quartz crystals, after 100 to 150 coatings with an average thickness of about 20 nm, the life of the crystal is reduced and it is better to replace it. It is recommended to work in the timed mode by covering the quartz crystal surface if you know the time and power required for deposition of the desired film thickness.

Can we use any flexible substrate for sputter coating? What is recommended?

The substrate used for the sputter coating should withstand a temperature of around 500 C, as it warms up during the deposition process. A common flexible susbrtate that is used for this purpose is Kapton tape/sheet, which is also used in energy storage systems.

To whom it may concern,

I was wondering if you could provide me a cost estimate for your most simple (and cost-effective) sputter coater that can coat with multiple materials.

Thanks,

Max

Hi Max

You can fill the form of Request Quotation in our website and we can help you better in this way.