Versatile Pulsed Laser Deposition and Thermal Evaporator System – PLD-T is a high vacuum thin film deposition system enables to deposit different materials by both Pulsed Laser Deposition and Thermal Evaporation technique (Not Simultaneously). It can deposit complex materials and crystalline structures onto substrates with very little setup involved.

Pulsed Laser Deposition technique leads to efficient, none-thermal ablation and preserves the stoichiometry of the target materials. By applying this method, it could deposit materials such as nitrides, oxides, super lattices, polymers, and composites. PLD-T with triple thermal sources can also deposit thin films through thermal evaporation.

PLD-T physical vapor deposition system is a multi-technique precise thin film coating device that enables the user to perform state of the art research projects in various fields like optics, electronics, solar cell fabrication, etc.

Features

Hardware

- High vacuum level with a built-in turbo pump

- Two-stage rotary vane backing pump (Diaphragm or scroll pump)

- High-current DC power supply suitable for thermal evaporation of different materials

- Quartz crystal monitoring system for real time thickness measurement (1 nm precision)

- Reactive gas injection control through precision Mass Flow meter (MFC)

- Full-range vacuum gauge

- Rotatory sample holder with adjustable rotation, height, and tilt (For 3-inch sample holders)

- Target manipulator with adjustable rotation speed

- 3 thermal sources and special feedthrough

- Equipped with electronic shutter (for thermal evaporation configuration)

- Equipped to motorized boat selection

- Two-year warranty

- Vac coat Products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

Automation

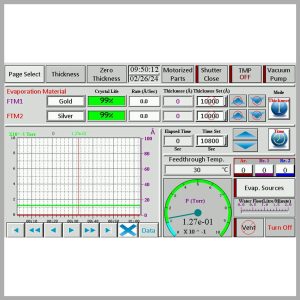

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software, updatable via network

- Semi-full automatic timed or thickness coating process (Optional)

- Deposition parameters adjustable though the touch screen panel (Optional)

- Records and plots coating parameters graphs

Optional Facilities

- 500 °C programmable substrate heater with software control

Target Manipulator

PLD deposition system is equipped with a multi-target manipulator which includes three 2 cm Dia. Targets are in standard size and all of our target manipulators are motorized, so as to enable automatic target selection and target rotation during the deposition process.

Thermal Evaporation

The Pulsed Laser Deposition System can be fitted with three independent heat resistance thermal evaporation sources. Different types of thermal evaporation sources (Boat, basket, and coil) can be installed on the thermal source holders for controlled thermal evaporation of a wide range of materials onto the substrate. The high-current power supply and low-voltage (Resistive) thermal evaporation platform are suitable for a wide variety of thermal evaporation applications. The thermal evaporation configuration is equipped with water-cooled feedthroughs accompanied by temperature sensor.

Thermal Sources Holders

The Pulsed Laser Deposition System can be fitted with three independent heat resistance thermal evaporation sources. The good design of the evaporation source holder causes no contamination transfer from a source materials to other ones. The length of source holders can be adjusted in the range of 5~10 cm to meet the user requirements.

Clean Vacuum

The PLD-T is designed with a 300 mm OD and 200 mm H, SST vacuum chamber. The PLD-T is fitted with an internally mounted turbo molecular pump, backed by a 6 m3/h two-stage rotary vane pump (Optional). It introduces a clean vacuum without oil contamination which normally exists with an ordinary diffusion pump.

Touch Screen Control

The pulsed laser deposition system, PLD-T, is equipped with a 7” colored touch-screen panel using user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touchscreen and the last 300 coatings are saved on the history page.

Specification of Pulsed Laser Deposion & Thermal Evaporator System

- Turbomolecular pump with different pumping speeds (Optional):

Pumping Speed 90 l/s 250 l/s 350 l/s Ultimate Pressure 8 x10-6 Torr 3×10-6 Torr 8×10-7 Torr - Unlimited deposition time without breaking the vacuum

- Records and plots coating parameters graphs

- Deposition process curves and data transfer by a USB port to PC

- 2 kW high-current power supply

- Water-cooled high-current electric feedthroughs

- Utilities: 220 V – 110 V, 50/60 HZ

- Dimensions: 500 mm H × 600 mm W × 470 mm D

- Weight: 50 kg (Pump, , and instrument case)

Applications

- Metal, semiconductor, and dielectric films

- Nano and microelectronic

- Solar cell applications

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

Options and Accessories

The PLD-T has the following options and accessories:

- Thermal evaporation sources (Boat/Basket/Coil)

- 500 °C substrate heater

- Thermal evaporation source materials

- Quartz crystal sensors

- Sealing gaskets