Laboratories commonly have safety rules to ensure the security of lab members and equipment from unwanted hazards. Laboratories safety rules for gas cylinders apply to labs with hazardous or compressed gas cylinders, where the lab staff should follow gas cylinder safety guidelines to guarantee protection against cylinder blasting and other hazardous situations.

Lab Safety Rules For Gas Cylinders

To have a safer working area inside a lab utilizing compressed gas cylinders, there are several safety tips to be noticed. Some of the major rules for the safe use of them are as follows:

1- Labeling

Compressed gas cylinders must be properly labeled so that they can be seen from any approach to the cylinder. Labels must be read and confirmed before using a cylinder

2- Storage

Gas cylinders must be kept:

-

- In an upright position

- In a secure and well-ventilated area with warning signs and a leak detection system for critical alerts (For hazardous gases)

- Attached to wall/floor stands/bolted wall straps/chaining to a rack to prevent tipping

- Away from direct sunlight and other heat sources, sparks, flames, electrical circuits, and other ignition sources

- Not near hallways, public areas, exits, or egress routes

- With the valve protection cap when not in use or attached to a system or structure

- With closed valves, and the pressure should be released on the regulators when cylinders are not in use

- Separately for cylinders of flammable and oxidizing gases

3- Transportation

Gas cylinders must always be transported in a well-ventilated vehicle and positioned upright with protective caps in place. Use a gas cylinder cart or stand to transport cylinders, rather than rolling them on the ground.

4- Inspection

Regular inspections ensure the safe handling, storage, and transportation of gas cylinders. Inspectors should visually check the cylinders and similar equipment at least once a month for the following items:

-

- Physical damage (E.g., corrosion, bulges, dents)

- Signs of leakage

- Appropriate labels

- Functionality

Gas Cylinder Applications

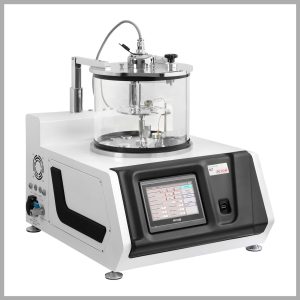

Compressed gas cylinders of different gases can be used for various applications. Argon gas cylinders are commonly used as an inert gas to have a clean chamber, like in sputter coaters, where the chamber pressure should be adjusted thoroughly to maintain a steady-state plasma for thin film deposition.

Vac Coat sputter coaters with electric leak valves or precision mass flow controllers (MFC) can accurately adjust the argon gas injection into the deposition chamber to control the chamber pressure.

Other gas cylinders, like oxygen and nitrogen, are also useful to perform reactive sputtering for the effective chemical reaction of the sputtered atoms with the gas to obtain a thin film with the desired chemical formula.

This article tried to point to some of the important rules for gas cylinders’ storage and transportation, where compressed gas cylinder safety guidelines might be useful. For more detailed safety guidelines one can refer to the following links.

Some of Vac Coat Products

References

- https://safetyculture.com/topics/gas-safety/gas-cylinder-safety/

- https://www.uab.edu/ehs/images/docs/gen/usestoragecompressedgascylinders.pdf

- https://ehs.oregonstate.edu/sites/ehs.oregonstate.edu/files/pdf/si/gas_cylinder_safety_si.pdf

- https://www.st-andrews.ac.uk/staff/policy/healthandsafety/publications/gascylinders-safeuseofgascylindersguidanc/#storage

- https://ehs.gatech.edu/chemical/lsm/9-12