Deposition of the highly reactive materials

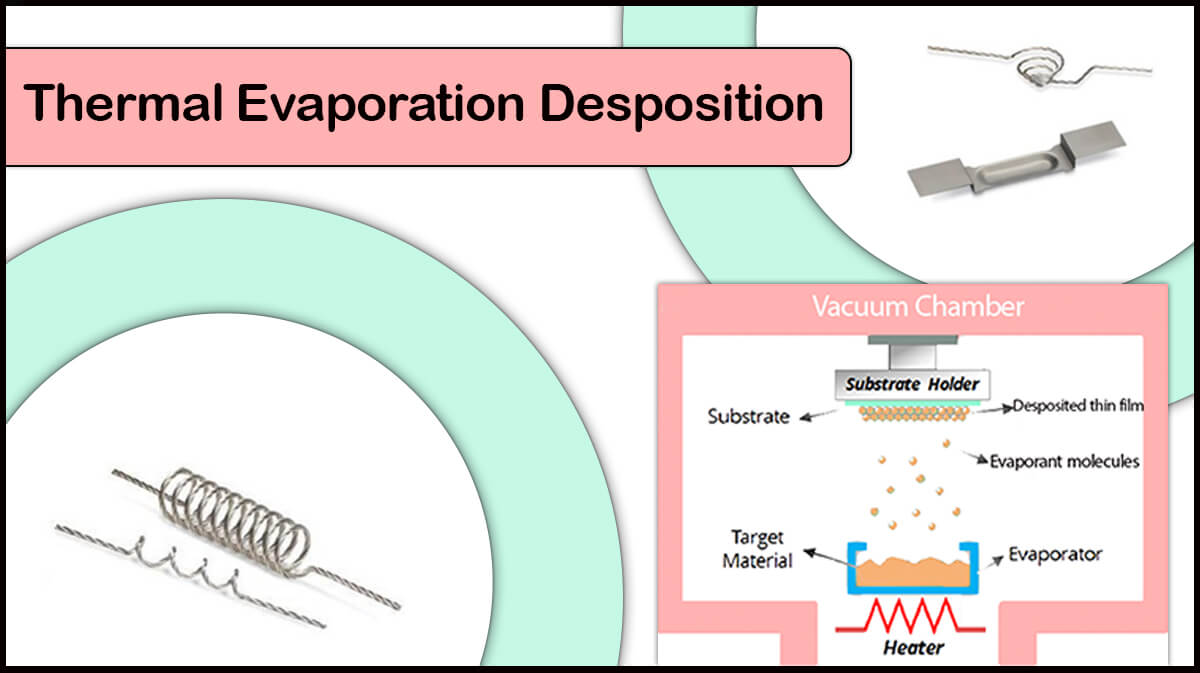

There are materials with a high affinity to oxygen among the materials which are deposited by the vacuum coating systems. If these substances are in the vicinity of a small amount of oxygen, they react quickly and burn completely. Lithium is easily oxidized when exposed to air. On the other hand, this alkali metal and its compounds have many applications in the industry. For example, this metal is used to produce rechargeable batteries that are used in smartphones, tablets, etc. The best way to lithium deposition is the thermal evaporation method.

Lithium Deposition

In the deposition of this metal with sputtering or electron gun methods, due to its low melting point, it is very difficult to control the deposition rate. Oxidation must be prevented in order to properly deposition the lithium, alloys or compounds. If lithium is oxidized, it needs a higher power to evaporate and break the oxide layer to melt the lithium. This high power causes the flash evaporation of lithium, which is not controlled. To prevent oxidation, lithium must be placed in the environment of inert argon gas or oil. To this end, Vac Coat Ltd. has made it possible for the DTT thermal evaporator to be able to integrate with a Glovebox to prevent the oxidation of materials such as lithium. If you want to evaporate the highly reactive materials such as lithium by a thermal evaporation method, be sure to see the specifications of the DTT thermal evaporation deposition produced by Vac Coat Ltd.