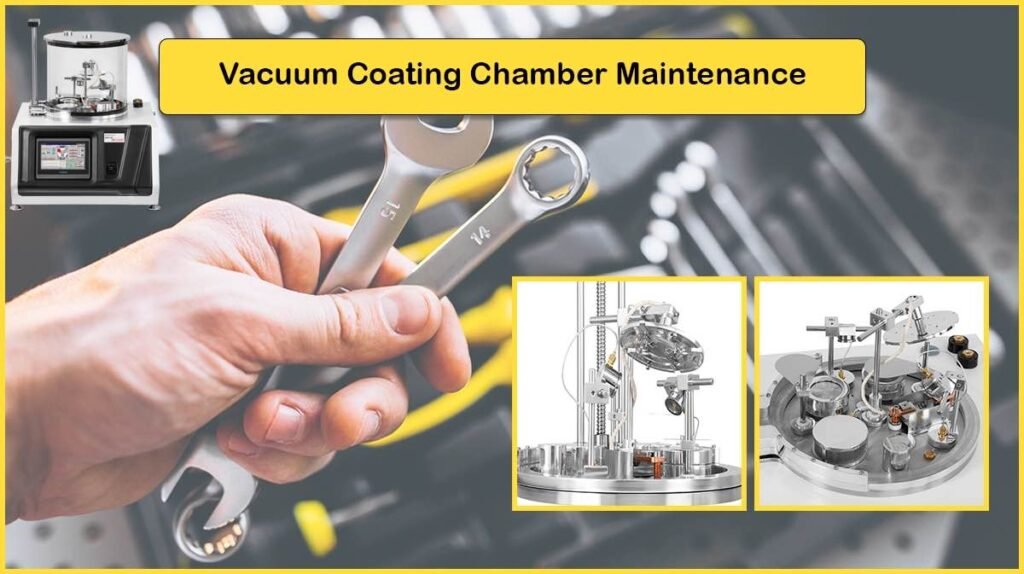

Vacuum Coating Chamber Maintenance

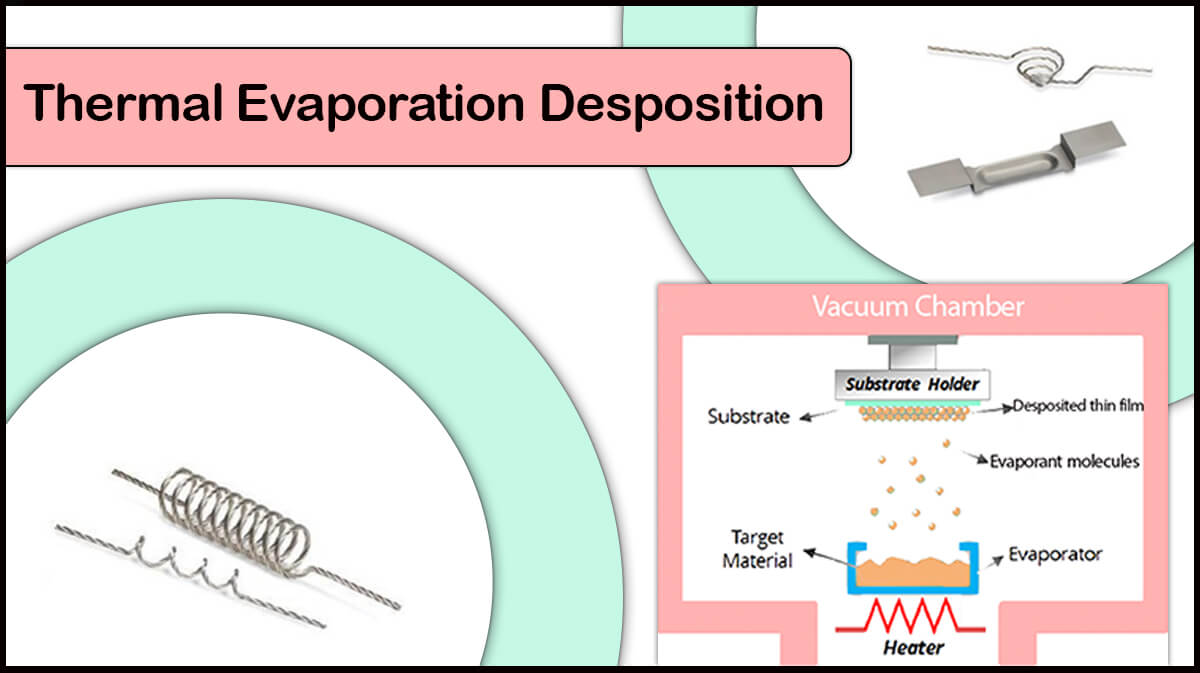

Vacuum chambers are the heart of a vacuum coating system. Maintenance of the vacuum coating chamber used in physical vapour deposition (PVD), including sputtering or thermal evaporation methods, is critical to ensure layer quality, repeatability, device uptime, and equipment lifespan. The main considerations in vacuum chamber maintenance include vacuum chamber cleaning from contamination, leak detection, inspecting O-rings and seals, and vacuum pump(s) servicing. A vacuum coating may also contain other parts like film thickness monitor, gas flow controller (MFC), cooling system, etc., that require frequent inspection and calibration.

What Is Called Contamination?

In general, contamination in a vacuum coating chamber is defined as anything that:

- Prevents the vacuum system from reaching the expected base pressure

- Introduces unwanted or destructive species into the deposited thin film

Alters the surface properties of the vacuum system in an undesired way.

Why Vacuum Coating Chamber Cleaning is Crucial?

If the vacuum coating system gets contaminated:

- The sample may get contaminated during the ventilation process.

- The flakes and debris resulting from successive coating processes may enter the pressure gauge and turbo pump inlet ports, interfering with their performance.

What Are Common Vacuum Chamber Contaminants?

Contamination sources in a vacuum coating chamber can be categorised into:

- particulate contamination, such as:

- Flaking of deposited film material on walls and fixtures

- Wear debris from surfaces in contact; i.e., opening and closing valves

- Debris from maintenance and installation; i.e., insertion of bolts, wear of tools, and from personnel clothing

- Unfiltered gas lines.

- Particulates coming from fixtures and substrates

- Particulates brought in with processing gases

- Particulates formed by gas phase nucleation of vaporised material or decomposition of chemical vapour precursors

- Vapour Contaminations:

- Water vapour, which is strongly adsorbed on clean metal and oxide surfaces

- Hydrocarbon vapours, originating from the vacuum pumping systems including oil pumps, like rotary pump

- Gaseous Contaminations:

- the processing gas can come from an impure gas source or contamination from the distribution line

How to Choose the Right Vacuum Coating Chamber Cleaning Method?

The vacuum chamber cleaning procedure should be chosen according to several considerations, including:

- Vacuum level of the coating chamber (LV, HV, or UHV)

- Particular performance requirements (e.g. low desorption)

- Minimising partial pressure of a particular contaminant (e.g. hydrocarbons)

- Chamber material

- Chamber construction

- Safety precautions

- Cost-effectiveness

The vacuum chamber should be carefully designed to avoid crevices, blind holes, cracks, and trapped volumes that may act as dirt and traps, and result in outgassing phenomenon. All Vac Coat vacuum coating chambers are designed to swiftly reach the expected vacuum level when proper maintenance is carried out.

Vacuum Chamber Cleaning Methods

Cleaning techniques for enhanced vacuum coating systems maintenance include:

- Flushing the system with a dry gas

- Blowing out debris with a high pressure air

- Washing out, wiping or rinsing with any general purpose solvent

- Using chemical agents like alcohols, detergents, organic solvents, or diluted acids

- Fine hand polishing to remove surface blemishes and scaling

Also, using a chamber liner/shield, like an aluminum foil, helps to keep the chamber glass clean and prevents radiation in case of RF sputtering.

Key Factors in Vacuum Chamber Maintenance

With the vacuum chamber being the main part of a vacuum coating system, its proper maintenance is crucial to obtain a clean thin film and enhance system lifespan. The vacuum chamber cleaning is one of the key procedures required after performing several deposition processes. The vacuum chamber cleaning techniques, depending on the coating material, chamber construction and material, vacuum level, etc., are briefly discussed in this article. For more information on this matter, you may refer to the listed references.