What is Scanning Electron Microscopy?

Scanning electron microscopy is an efficient and non-destructive technique that provides detailed information on the morphology, composition, and structure of the studied materials. The first one of this electron microscope was invented in 1942. It was shown at that time that Secondary Electrons (SE) produced topographic contrast using the collector positive bias rather than the sample. After that, many changes were made until the first commercial sample of scanning electron microscope was introduced in 1965.

An Overview of Scanning Electron Microscopy

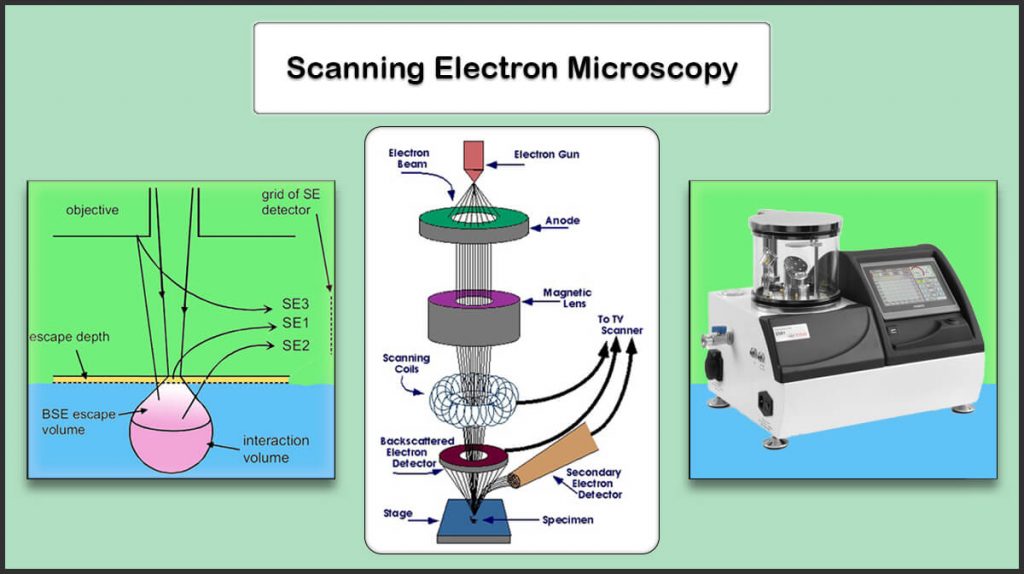

In this microscopy, two classes of electrons are detected: secondary electrons (SE) and backscattered electrons (BSE). Backscattered electrons are the redirected electrons of the elastically collided electron beam with the sample, where secondary electrons originate from the sample atoms and result from the inelastic collision of the electron beam with the sample with less energy than backscattered electrons.

As a result of the inelastic collision of the electron beam with the sample surface, the energy of the electron beam electrons is transferred to the conduction band electrons and sometimes the valence band of the sample which separates these electrons from the sample atom, which is called secondary electrons. BSEs return from deeper points of the sample and depend on the atomic number of the material, the larger the atomic number, the material appears in the brighter image.

The SEs are sampled from the more superficial areas and provide a lot of surface detail information. As a result, these two groups of electrons carry different information (Figure 1).

Scanning Electron Microscope Parts

This Microscope consists of several parts:

- An electron source

- Electromagnetic lenses that focus the generated electron beam on the specimen

- SEM stub, on which the specimen is mounted

- Electron detector

- And image processing facilities

Electron Source

The electron source in the microscope have been improved since its invention. In conventional electron microscopy the electrons are separated from the filament by resistively heating the tungsten filament and the anode accelerates the electron beam after leaving the thermionic source. The tungsten electron filament, with a diameter of about 100 mm, is the most common types of electron source mainly due to its low price point, high reliability, and suitability for low magnification imaging. Owing to the thermionic emission of the heated tungsten, the electron spread to a wide trajectory from the source. You can read more about Electron Microscope here …

Electromagnetic Lenses

The electron beam with the energy ranging from 0.2 keV to 40 keV, is focused onto a spot about 0.4 nm to 5 nm in diameter by one or two condenser lenses. The beam goes through pairs of scanning coils or deflector plates placed in the final lens, which bend the beam in the x and y axes so that it can scan over a rectangular area on the sample surface.

Sample Preparation

In the case of samples that are not electrically conductive, such as dielectrics and semiconductor materials, a sample preparation process is required prior to imaging. Due to the collision of the electron beam in the imaging process using electron microscopy, the non-conductive structure of these specimens traps electrons on the surface of the material and thus causes the surface to temporarily become charged. This phenomenon causes white areas appearing in the image captured by the electron microscope. The conductive layer deposited on the sample prior to the microscopic process acts as a channel and eliminates the charges created on the sample surface.

Also, the presence of a conductive layer on the sample stimulates secondary electrons, especially at the surface. A conductive coating is appropriate when the topographic features of the specimens are not significantly enlarged or hidden. The selected material must have a suitable secondary electron emission coefficient to help improve image contrast.

The optimum thin film conditions for coating scanning electron microscopy specimens are obtained when the thin film is of minimum thickness (0.5 to 3 nm) and contains fine grain size so in addition to removing the excess electrical charges on the sample, it also improves contrast in low-density materials. Moreover, conductive layer grains should have low surface mobility, such that they do not affect the sample appearance, and be smaller than the probe diameter.

What is Field Emission Scanning Electron Microscope?

Scanning electron microscopy is a highly efficient method for imaging micro-nano structures. It has improved enormously to enhance image quality, leading to invention of new techniques like FE-SEM. You can read more about Field Emission Scanning Electron Microscope and difference between it and SEM here …

Vac Coat SEM Coaters

Vac Coat sputter and carbon coaters provide conductive layer deposition for SEM and FESEM sample preparation equipped with rotary pump (DSR1, DSCR) for low vacuum and Turbomolecular pump (DST1, DSCT) for high vacuum deposition.

Vac Coat also offers DST3-T sputtering system plus thermal deposition with Turbomolecular pump to deposit composite layers of several materials. This coating system with the optional RF generator and plasma cleaner can provide deposition of a wide range of conducting and semi-conducting materials.

References

- Abd Mutalib, M., et al. “Scanning electron microscopy and energy-dispersive X-ray (EDX) spectroscopy.” Membrane characterization. Elsevier, 2017. 161-179.

- https://t.ly/6p9rx

- https://t.ly/mKUbN

- https://t.ly/io3dX

- https://t.ly/be6GE