The desk SEM coater model DSCR is a compact coating system enabling both sputter and carbon coating. The DSCR is able to sputter noble metals such as gold (Au), palladium (Pd), platinum (Pt), and gold/palladium (Au/Pd), as well as thermal evaporation of different carbon sources (Fiber or rod) to coat on samples with non-conductive or poorly conductive surface for electron microscopy imaging or other applications.

The DSCR is a rotary pumped coater configured for DC sputtering and carbon fiber (Thread) or carbon rod coating with interchangeable heads in one instrument.

Since sputtering deposition and carbon evaporation are standard mechanisms to sample preparation for increasing the surface electrical conductivity of the scanning electron microscope (SEM) samples to prevent charge buildup during the imaging process, DSCR is a versatile machine for SEM sample preparation.

The full-automatic sputter and carbon coating processes allows easy, precise, and repeatable performance. DSCR can be equipped with a water-cooled sputtering cathode which make it suitable for long time deposition. The maximum size of substrates in this model could be 4 inches.

Features of DSCR

Hardware

- Two-stage, direct drive rotary vane pump 6 m3/h

- 80 W DC switching power supply for sputtering

- 0-25 A pulsed DC power supply for carbon fiber evaporation

- 0-100 A DC power supply for carbon rod evaporation (Optional)

- Quartz crystal thickness monitor with precision of 1 nm and resolution of 1 Å

- One 2-inch magnetron cathode

- Electronic venting valve

- Sample rotation, height, and tilt adjustable

- Planetary sample holder (Optional)

- Electronic shutter

- Easy-to-change specimen stages (Rotation stage as standard)

- Two-year warranty

- CE conformity

- Vac Coat products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

Automation

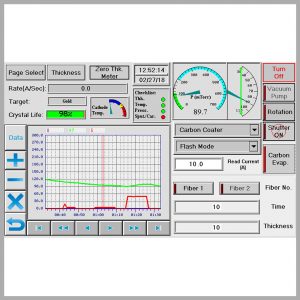

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software, updatable via network

- Precise control over coating rate to achieve finer grain structures

- Semi-full automatic sputtering

- Semi-full automatic carbon fiber/rod deposition process

- Repeatable and programmable sputtering and carbon coating process in the automatic mode

- Manual or automatic timed and thickness sputtering deposition

- Records and plots coating parameters graphs

- Storing coating recipes for repeatable depositions

Pulsed Carbon Fiber Evaporation

The DSCR is able to perform pulsed carbon fiber evaporation. Short pulses provide more controlled deposition and significantly reduces the amount of debris associated with traditional carbon deposition.

Carbon Rod Evaporation (Optional)

The DSCR could be equipped with carbon rod evaporator head (Optional). For this case an external 0-100 A high current power supply should be used instead of the internal high current power supply which is designed for carbon fiber evaporation.

Touch Screen Control

DSCR, the desk SEM coater, is equipped with a 7” colored touch screen panel and full automatic control using a user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen. The last 300 coatings information is saved on the history page.

Sample Holder Stages

The DSCR can be equipped with different sample stage configurations depending on the user requirements. The standard sample stage is rotatable with adjustable height and angle and can be changed easily. The rotary planetary sample stage is a good choice for uniform coating of porous specimens (Optional).

Applications of DSCR

- Fine grain structural deposition of noble metals for SEM, FE-SEM, EDX, and TEM sample preparation

- Conductive layers

- GLAD sputtering

- TEM grid plasma treatment for improved hydrophilicity (Optional)

Specification of DSCR

- Suitable for deposition of noble metals, carbon fiber, and rod (Optional)

- 170 mm OD x 140 mm H Pyrex cylinder chamber

- Dimensions: 45 cm H x 50 cm W x 37 cm D

- Ultimate vacuum: Less than 40 mTorr

- Automatic control of the cathode’s temperature to protect the lifetime of the magnets

- Rapid data input through fully automatic touch screen panel

- Real-time plot of coating parameters

- Deposition process data transfer to PC by USB port

- Utilities: 220 V-110 V, 50/60 HZ – 1.7 kW

- Shipping weight: 42 Kg

Options and Accessories

- Head and external power supply for carbon rod evaporation

- Quartz crystal sensor

- Planetary sample rotation stage

- Spare cylindrical vacuum glass chamber

- Sputtering targets

- Sealing gaskets

- Plasma cleaner

Carbon fiber source