Applications of Plasma Treatment in Microfluidics

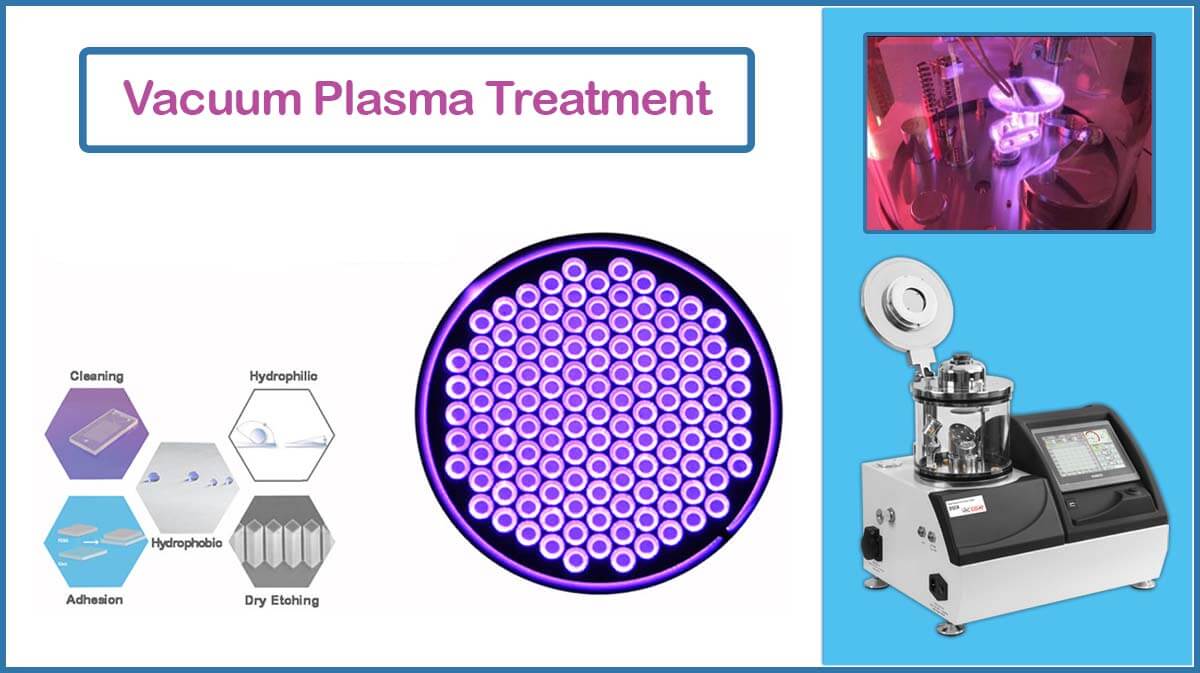

Plasma is the fourth state of matter, and in today’s high technology, is being used widely in many fields such as electrical engineering, optics, printing, painting, medical, mechanical, and textile. Plasma treatment is used to improve the surface properties of a broad range of materials by cleaning the contaminants from surfaces before manufacturing processes and functionalizing the surfaces with large quantities of reactive chemical species.

The plasma pre-treatment process raises the surface energy and results in disinfection, cleanness, and modification of surfaces to prepare them for adhesive bonding, and coating processes. In this way, the surface features such as hydrophobicity or hydrophilicity, and corrosion protection, all would be influenced by plasma treatment.

Microscopic contaminants such as organics contamination exist on almost all surfaces. Plasma cleaning is applied to most materials along with surfaces for the removal of organics contamination before the coating process. In the cleaning process, the contaminants are removed efficiently at the molecular level by converting into gaseous products through chemical reaction or physical ablation of hydrocarbons. In addition, the cleaning process enhances the reliability of the adhesive bonding between the surface and the target molecules.

Microfluidic Devises Cleaning & PDMS Bonding

Microfluidics is the technology of manufacturing micro-sized devices used to measure the fluids’ molecular diffusion coefficients, viscosity, pH, and chemical binding coefficients while flowing through the microchannels. Polydimethylsiloxane (PDMS) is a low cost, and transparent material widely used in microfluidics fabrication due to its rapid development and adjustable for few nm resolution patterning. It is a type of inert silicone that can be molded by easily injecting it into microfluidic channels. The pattern of the mold is transferred to PDMS by casting it on the mold and peeling it off. But it has a poor adhesion to glass and requires a surface treatment to create a permanent and strong bonding between PDMS and glass substrate.

Plasma treatment in microfluidic devices used to create a permanent and strong bonding between PDMS and glass substrate. Regarding the application of plasma treatment in the removal of any microscopic contaminants, and functionalizing the surface with specific chemical groups, the best suggestion is to treat the surface of PDMS with plasma. Plasma treatment produces (-OH) groups on the PDMS surface with hydrophilic property which enhances the strong covalent bonds (Si– O–Si) when brought in contact with glass substrate as well as improving the flow of analyte within microchannels, or creates water-tight microchannels. So, the casted parts are placed in oxygen plasma with glass or silicon-containing parts.

When these pieces are activated with oxygen plasma and then carefully put together, a kind of covalent bond is formed between them. In other words, a very strong bond is created between the PDMS part and the mating part by sharing electrons. So, in summary, the plasma treatment helps in removal of hydrocarbon groups, and exposing to hydrophilic -OH groups which considerably improves bonding between PDMS and glass substrates and also the -OH groups improve significantly the analyte flow.

Also, the contact angle measurements indicate that increasing the time or power of a plasma treatment on PDMS leads to the surface becoming more hydrophilic. For instance, an oxygen plasma removes organic, hydrocarbon contaminations with the help of highly reactive and energetic oxygen radicals. This chemical reaction creates surface functional groups of silanol (SiOH) that result in the hydrophilicity of the surface.

Challenges of Plasma Activation and Bonding in Microfluidic Devices

Careful planning and reasonable process control are required to produce a high-quality microfluidic device with a strong bond between its components. Particle contamination management during the process and temperature control of materials before and during plasma activation are very important steps in the production of a reliable microfluidic device.

Accurate and reproducible control of the plasma process is critical to the production of highly reliable plasma-activated PDMS components for microfluidic device production. Plasma activation processes that are carefully controlled lead to the optimization of microfluidic bond strength without any adhesives. Choosing a plasma system with proper control, instrumentation, optimal material, and process selection is the key to achieve the highest possible bond strength.

1- Pressure Control

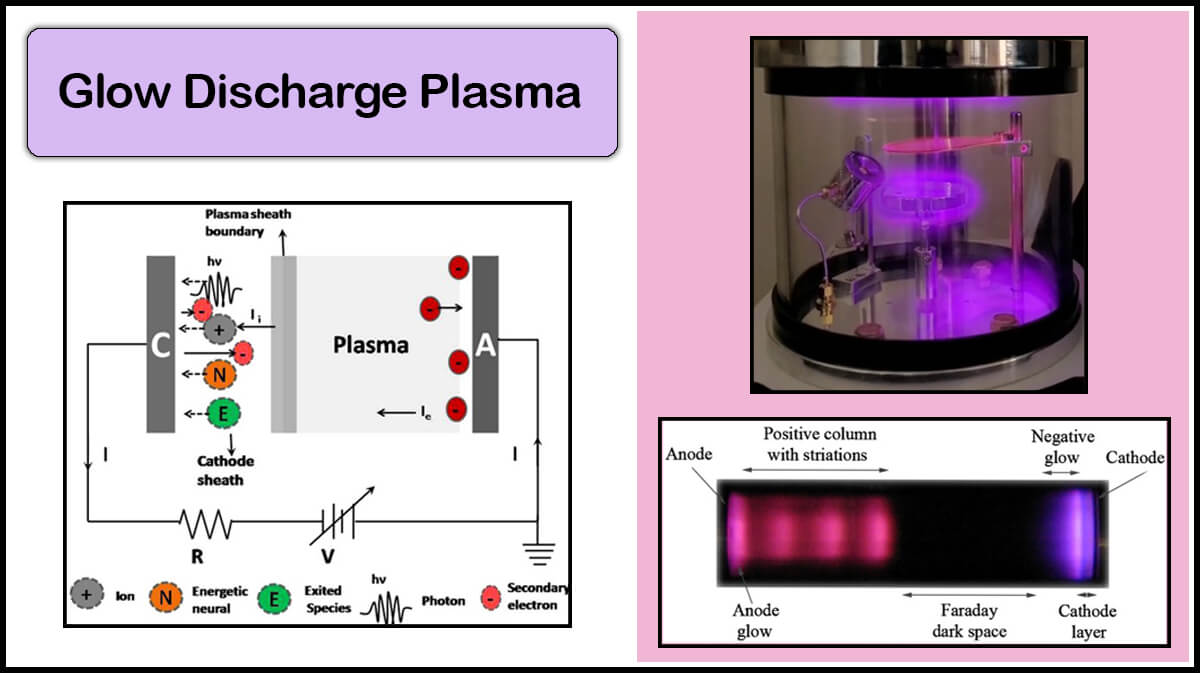

Pressure determines the concentration of the oxygen plasma in contact with the PDMS surface and silicon-containing parts. So, precise pressure control is one of the essential parameters in controlling the plasma activation process. The injection of gas into the vacuum chamber is continuously adjusted and controlled at the desired point by having an automatic process control loop between the pressure gauge and the mass flow control valve.

2- Particle Contamination Management

A clean work environment is one of the most important issues in creating a desirable microfluidic device. If the chamber used to combine and store the PDMS is not clean, the PDMS can be easily contaminated. An important factor is preventing and controlling any contamination arising from vacuum chamber material. The most common type of plasma chamber is made of aluminum or stainless steel, which can be a source of particle contamination due to the possibility of sputtering the chamber constituents. This sputtering usually occurs due to the high density of plasma in the vacuum chamber. So, generally, the borosilicate or quartz glass chambers are ideal to fabricate microfluidics.

3- Temperature Control

Controlling the temperature of the PDMS during the plasma activation process is also another crucial parameter for the production of microfluidics. A slight change in the flexibility and conformal flow of the material can be achieved by controlling the temperature of the components. If the temperature of the material is too cold, the fluidity and flexibility of the material will be low and the opposing forces will prevent the materials to be combined. On the other hand, materials are smoother at higher temperatures, and higher flexibility results in better bonding. Temperature control of PDMS components during activation and bonding can increase bond strength.

Some of Vac Coat Products

References

- Norizah et al. / Jurnal Teknologi (Sciences & Engineering) 74:10 (2015) 57–61.

- https://plasmatreatment.co.uk/pt/plasma-treatments/plasma-surface-activation-to-improve-adhesion/pdms-bonding-microfluidics

- https://princetonscientific.com/plasma-treatment-equipment/plasma-applications/plasma-treatment-of-pdms-for-microfluidics/