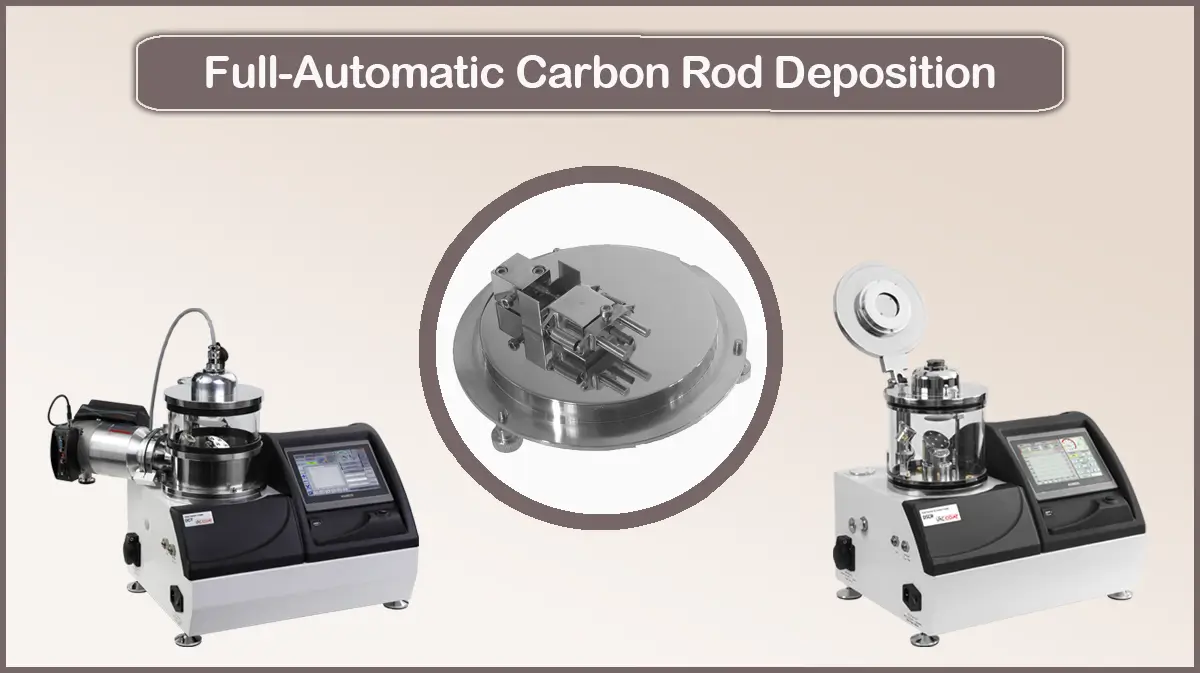

Vac Coat carbon coaters are upgraded to full-automatic deposition procedure for carbon rod evaporation. The programmable coating process enables repeatable, precision thin film deposition as required for high-grade research works.

Carbon rod evaporation and deposition process now can be programmed and executed automatically with touch-screen controllable power source, which formerly performed in a semi-automatic procedure.

A repeatable, reliable coating procedure to achieve a steady-state thin film deposition is crucial to obtain the best results in research works, where high-accuracy is desired. A programmable full-automatic coating eliminates human errors during the deposition process to produce the same result in each coating sequence.

Carbon coating is a favorite method for SEM sample preparation to create a thin conductive layer on the sample, hence avoiding charging effects during SEM or TEM imaging. A reproducible coating process ensures verified comparison of the different samples’ structures. Carbon rod is a favorable source for carbon evaporation which eradicates debris, unlike carbon fiber, and is more controllable to achieve the desired thickness.

Vac Coat permanently improves its devices and services to meet the needs of its valuable customers. Vac Coat low and high-vacuum carbon coaters DCR and DCT, and the hybrid coating systems DSCR, DSCT, and DSCT-T are now enabled to perform full-automatic carbon fiber/rod deposition. The automatic carbon coating mode of Vac Coat carbon coaters allows highly controlled carbon coating procedure where high-precision is needed.