Vac Coat Ltd. introduces its new product, DSCT-300, enabling sputter and carbon coating processes in a desktop coater with a large chamber, without the need to break the vacuum to switch between the sputter coating and carbon coating.

The DSCT-300, containing both a sputtering cathode and carbon source holder on the deposition chamber lid, empowers high vacuum sputtering deposition of noble and oxidizing metals by DC sputtering, as well as RF sputter coating of semiconductors and insulating sputtering targets.

Carbon evaporation deposition is also available through the installed head on the chamber’s lid, with separate heads for carbon threads (Fiber) or carbon rod source holders.

The DSCT-300 model is ideal for uniform deposition on larger substrates, supplied with a 4-inch rotating sample holder stage, or deposition on several small samples, as used in sample preparation and metalizing for electron microscopy, like FE-SEM and TEM.

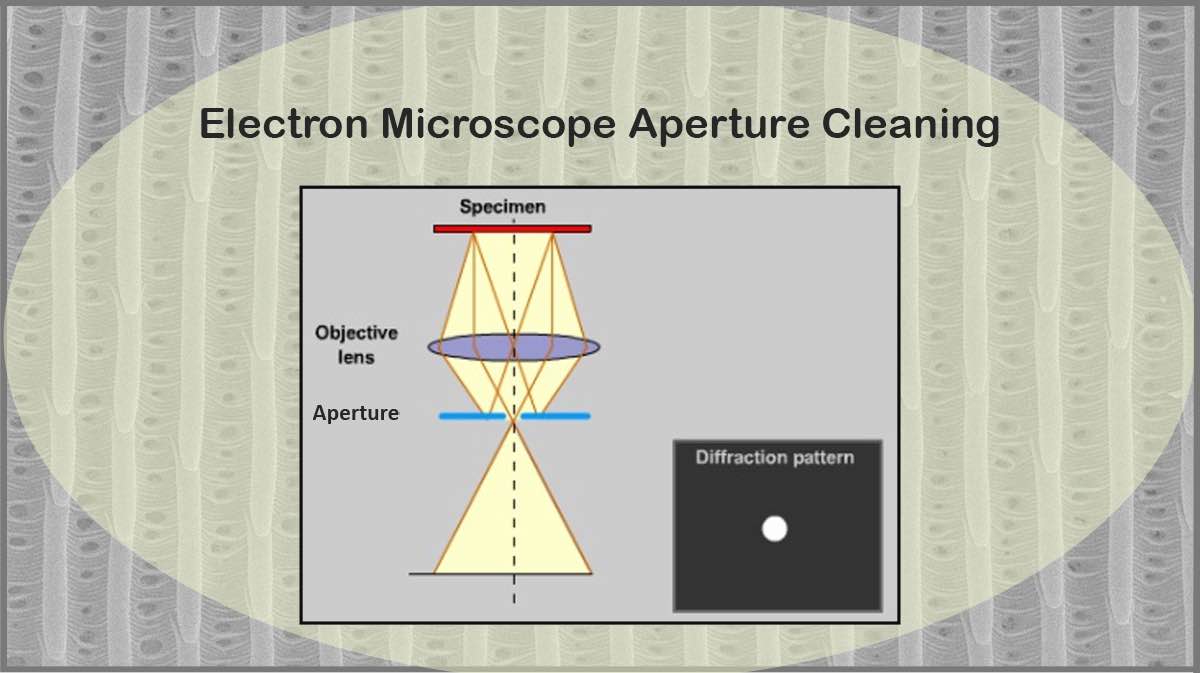

This model can also be supplied with an extra head with high-current feed-throughs for thermal evaporation of metal sources, named DSCT-T-300, allowing TEM aperture cleaning.

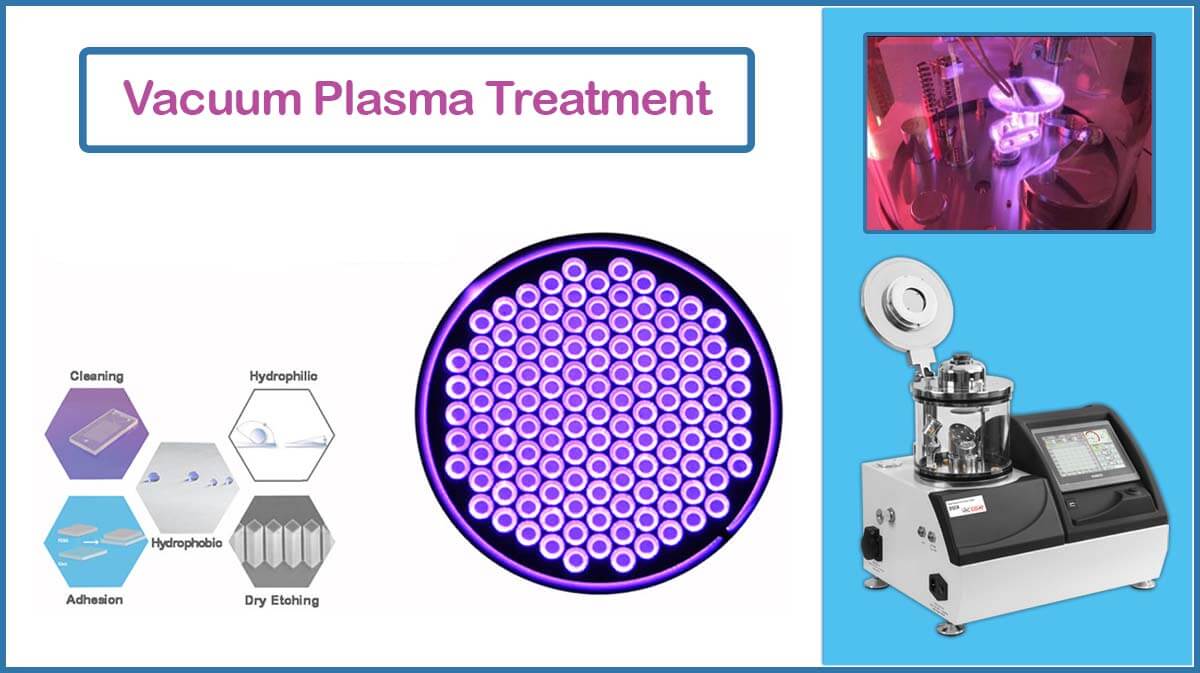

Vac Coat coating systems can be customized according to the customer’s requirements. The DSCT-300 can be provided with several optional features, such as glow discharge plasma for plasma treatment of the surfaces for making hydrophilic or hydrophobic surfaces, planetary sample rotation stage, GLAD sputtering, etc.