What is Quartz Crystal Microbalance or QCM?

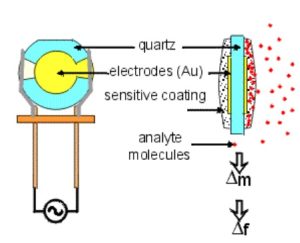

A quartz crystal microbalance (QCM) sensor is a piezoelectric crystal that detects the extra mass placed on it based on the change in its resonating frequency. The sensor surface can be functionalized to distinguish specific species, useful in bio-sensing or monitoring the environment.

What is A Piezoelectric Crystal?

Solid materials whose atoms or molecules are regularly and repeatedly called crystals (The structure of these cells has a unit cell). Piezoelectric materials are electrically neutral and although the structures of the atoms of these materials are not symmetric, they neutralize each other in terms of electric charge. When a mechanical force is drawn into the piezoelectric material, the distance between the atoms is changed, and they move away from or toward each other. As a result, the electrical charges are distributed unevenly and a net positive or negative charge is generated.

On the other hand, when an alternative electric (AC) field is applied the crystal it starts to resonate with a specific frequency which depends on the shape, mass, thickness, and applied flow to the crystal.

Quartz Crystal Application

Due to the high sensitivity of the quartz crystal resonating frequency to the additional mass on its surface, it is widely used as a bulk acoustic wave (BAW) resonator-based mass sensor for real-time sensing of low concentrations of materials in different environments. Subsequently, gaseous molecules in air and dissolved particles in different analyzes can be detected due to their weight when deposited on the crystal surface.

How to Measure the Mass Deposited on A Quartz Crystal?

Deposition of the different materials’ atoms on the crystal during the coating process causes the crystal mass to change and leads to a change in the crystal resonating frequency. The relation between the frequency change (Δf) and the deposited mass (Δm) is defined as Sauerbrey’s equation, developed by Günter Sauerbrey in 1959:

![]()

Where f0 is the initial crystal frequency, E is Young’s modulus, ρ is the density, and A is the area.

QCM Parts

The crystal used in the thickness gauges is usually called a Quartz Crystal Microbalance (QCM) and consists of three parts:

- Quartz crystal sensor with operational characteristics like frequency range, resistance, and electrode quality

- Sensor head which regulates the temperature

- Electronic monitor or controller that supplies the electric current that forces the crystal to vibrate and tracks the crystal frequency with an internal microprocessor that converts the frequency difference into the actual film thickness

QCM Sensors

Typically, a quartz crystal thickness monitor has a characteristic frequency of 6 MHz, and when the crystal surface is covered by atoms, its initial frequency decreases. The frequency counter circuit calculates the frequency variation and converts it to a thickness value, based on Sauerbrey’s equation.

Quartz Crystal Electrode

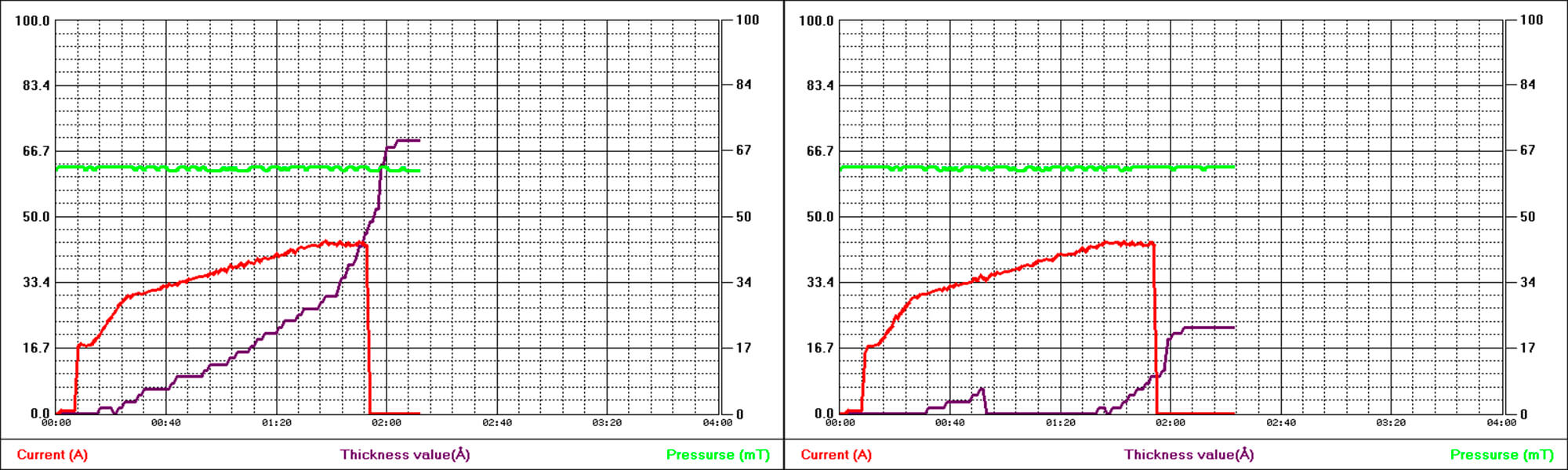

Quartz crystal electrode quality can determine the sensor efficiency in thin film thickness monitoring. Quartz crystals with gold electrodes (Gold-coated QCM) are common in thickness measurement, and they work well for normal evaporation conditions like metal evaporation or sputtering deposition, where a steady-state deposition procedure is happening.

However, in high current deposition processes, such as carbon rod ramped evaporation, silver-coated QCM is more efficient than gold-coated one. A gold-coated QCM, despite QCM with silver contacts, does not display the thickness of the deposited layer till the end of the coating process.

All Vac Coat coating devices can be supplied with quartz crystals for thin film deposition rate monitoring, capable of real-time measuring of the coated layer with 1 nm precision and 1 angstrom resolution. Vac Coat manufactures vacuum coating systems, including sputter coaters, carbon coaters, and thermal evaporators, that work based on the physical vapor deposition technique for thin film deposition.

Some of Vac Coat Products

References

- Alanazi, Nadyah, Maram Almutairi, and Abdullah N. Alodhayb. “A Review of Quartz Crystal Microbalance for Chemical and Biological Sensing Applications.” Sensing and Imaging 24.1 (2023): 10.

- https://www.philliptech.com/qcm/

- https://www.biolinscientific.com/hubfs/Content%20Offer/QSense/EN/The%20Sauerbrey%20relation%20v2.pdf?hsLang=en#:~:text=The%20Sauerbrey%20equation%20is%20a,to%20a%20QCM%20crystal%20surface.

- https://en.wikipedia.org/wiki/Sauerbrey_equation

- Tetyana, Phumlani, Poslet Morgan Shumbula, and Zikhona Njengele-Tetyana. “Biosensors: design, development and applications.” Nanopores. IntechOpen, 2021.

- Maglio, O., Costanzo, S., Cercola, R., Zambrano, G., Mauro, M., Battaglia, R., Ferrini, G., Nastri, F., Pavone, V. and Lombardi, A., 2017. A quartz crystal microbalance immunosensor for stem cell selection and extraction. Sensors, 17(12), p.2747.

- Scarano, Simona, Stefano Mariani, and Maria Minunni. “Label free Affinity sensing: application to food analysis.” Acta Imeko 5.1 (2016): 36-44.

- Yuwono, Arief Sabdo, et al. “Odour pollution in the environment: Development of a measuring system.” Proc. of International Conference on Tropical Agriculture. 2001.

- Bourennane, A., Tanougast, C., Diou, C., & Gorse, J. (2023). Accurate Multi-Channel QCM Sensor Measurement Enabled by FPGA-Based Embedded System Using GPS. Electronics, 12(12), 2666.

- Boiadjiev, S. (2008). Thin films deposition on quartz crystal resonators for applications in gas sensors.