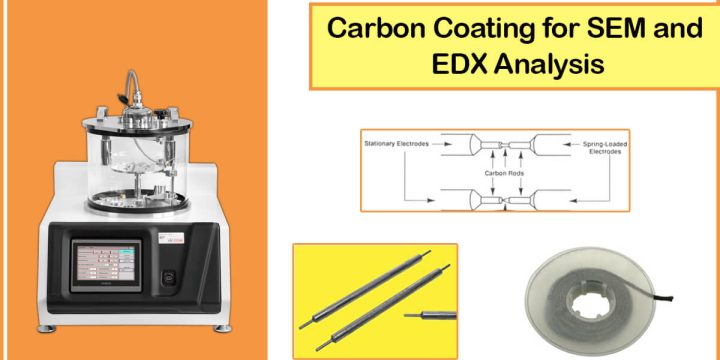

Carbon Coating for EM and EDX Sample Preparation

[vc_row][vc_column width="3/4"][vc_row_inner][vc_column_inner][vc_column_text css=""] Carbon Coating for EM and EDX Sample Preparation Carbon coating as a sample preparation step for analysis by electron microscopy and energy dispersive X-Ray spectroscopy (EDX or EDS) can significantly improve the resolution of structural and chemical analysis. Vac Coat low and high vacuum carbon coaters can provide the best carbon coat through fiber/rod carbon evaporation for research purposes. [/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner css=".vc_custom_1716380589066{background-color: #d9d9d9 !important;}"][vc_column_inner width="1/2"][vc_video link="https://youtu.be/fvpa8kr8M1c?si=u5sOOOeLDoI_vPlv"][vc_column_text css=".vc_custom_1716380465809{margin-top: -20px !important;}"] SEM: Carbon Coating Using Rods [/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_cta h2="" txt_align="center" style="3d" color="mulled-wine" el_width="lg" add_button="bottom" btn_title="Carbon Coaters" btn_style="3d" btn_color="juicy-pink" btn_align="center" css="" btn_link="url:https%3A%2F%2Fvaccoat.com%2Fcarbon-coater%2F|title:Carbon%20Coaters%20%7C%20Vac%20Coat%20Desk%20Carbon%20Coaters|target:_blank"] [/vc_cta][/vc_column_inner][/vc_row_inner][vc_row_inner][vc_column_inner][vc_column_text css=""] Why Do Some Samples Need Coating Before Analysis? Electron microscopes and analytical methods using X-rays are powerful tools that provide valuable information at the nanoscale of various samples. However, some samples, such as biological, radiation-sensitive, or poorly…