A detailed video on the operation of Vac Coat Desk Thermal Evaporator (DTT) for gold/chromium thin film deposition has recently uploaded by a Macquarie University Professor, David Inglis, an associate professor at Macquarie University School of Engineering, working on microfluidics and nano-biotechnology with an extended scientific network around the world.

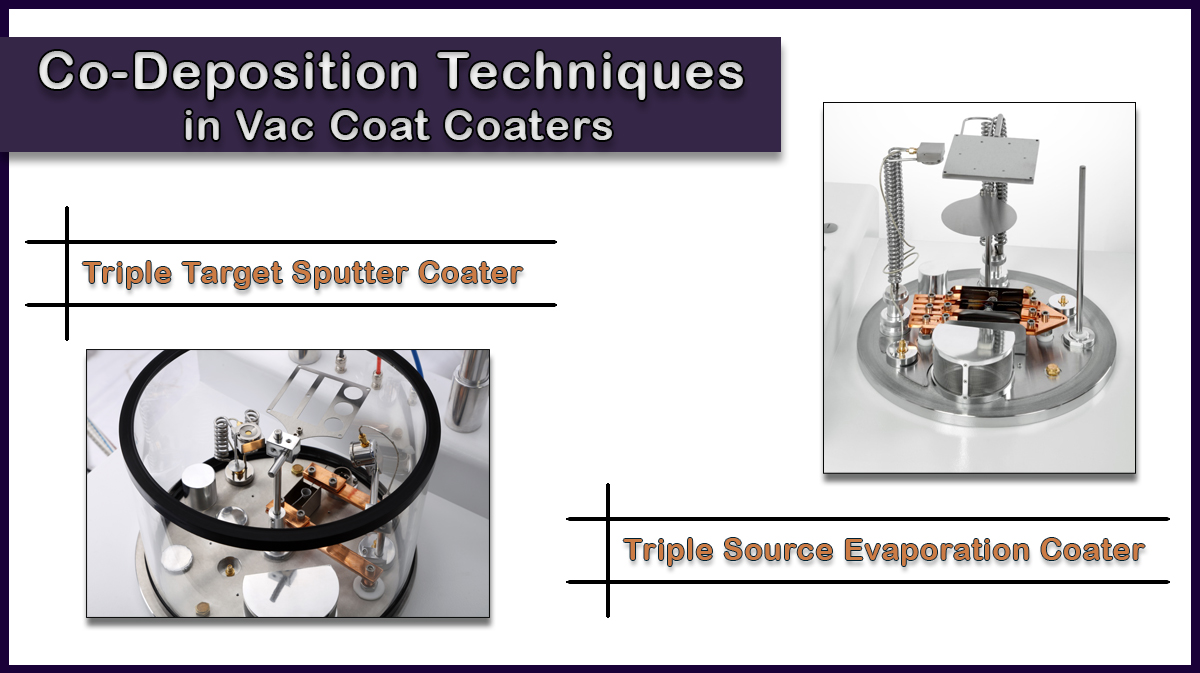

Vac Coat turbo-pumped thermal evaporator DTT, with a 300 mm Dia. chamber and three evaporation source holders, is capable of timed or thickness thin film deposition of various materials, like gold, chromium, and many other low-evaporation-temperature substances. DTT three-source holder configuration is advantageous in forming layered thin films (without breaking the vacuum) or simultaneous deposition of materials to make alloys (You can read more about co-deposition here). Also, the large chamber helps to continue the deposition process for longer times (up to 30 minutes). This model can be equipped with an extra glass chamber to increase the sample-source distance to deposit more uniform thin films.

Vac Coat as a manufacturer of vacuum coating systems based on physical vapor deposition, also offers a smaller desktop thermal evaporator DTE, with 170 mm Dia. chamber, which is suitable for short-term deposition process. DTE is an ideal SEM coater for electron microscope sample preparation, since it can be vacuumed quickly up to 10-5 Torr due to its small chamber.