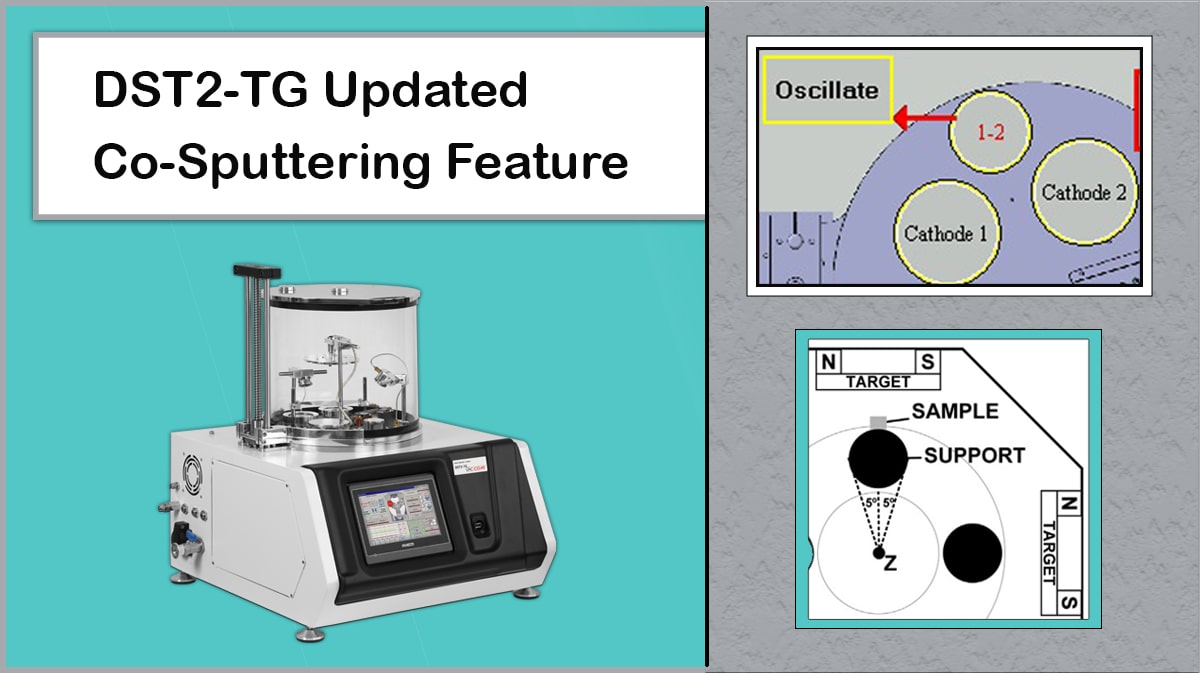

The DST2-TG sputtering system has recently been updated to perform co-sputtering with incredibly enhanced efficiency.

In the new version of the DST2-TG coating system, the sample holder position can oscillate between the two magnetron cathodes, controlled with extra deposition parameters, like oscillation degree and period on the motorized parts page (Figure 1). Through this feature, DST2-TG is empowered to deposit more uniform coatings, such as layered thin films, on the oscillating substrate.

A recent study on the high wear-resistant CrN (as a transition metal nitride) presented that if the substrate is oscillated by 5° with a period of 120 s while producing the multilayer structure (Figure 2), the resulting coating shows elevated hardness.

For more information, follow the link below:

Vac Coat is the designer and manufacturer of vacuum coating instruments, like sputter coaters, carbon coaters, and thermal evaporators which can be customized due to the consumer’s need. The DST2-TG deposition system is provided with special feed-throughs that can also be integrated into a glovebox for the deposition of sensitive layers.

Some of Vac Coat Products

References

Guimaraes, M. C. R., de Castilho, B. C. N. M., de Souza Nossa, T., Avila, P. R. T., Cucatti, S., Alvarez, F., … & Pinto, H. C. (2018). On the effect of substrate oscillation on CrN coatings deposited by HiPIMS and dcMS. Surface and Coatings Technology, 340, 112-120.