What Is DC Sputtering?

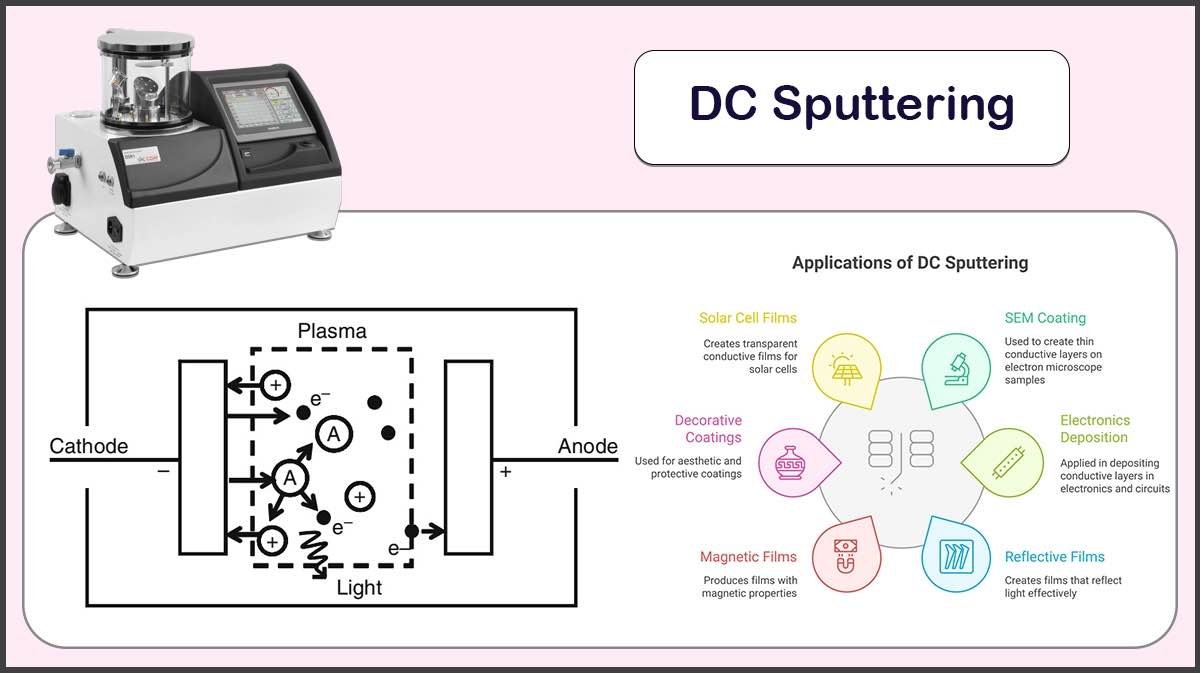

Direct Current sputtering, also known as DC sputtering, a subclass of diode sputtering, is a common method used to deposit thin films of conductive materials. Applying a DC voltage between the cathode and anode in a vacuum chamber results in the formation of energetic plasma ions, bombarding the target material on the cathode and ejecting its atoms, which are then deposited on the substrate.

DC-diode sputtering offers the advantage of simple performance; however, its operation is limited to conductive targets due to charge buildup on insulator target surfaces during ion bombardment, which is overcome in RF sputtering deposition. Also, achieving high uniformity and deposition rate is challenging in this method.

Nowadays, DC sputter coating is widely used in different fields, including electronics, optical coatings, functional and decorative coatings, packaging, and medical instruments, due to the cost-effective and controllable process, as well as good layer adhesion.

How Does a DC Sputtering System Work?

DC sputtering systems operate based on the high DC voltage difference applied between planar electrodes, the cathode and the anode. This leads to glow discharge plasma generation inside the sputtering chamber, which is formerly injected with a process gas like Argon at a pressure in the millitorr range. The charged particles of the process gas plasma, like Ar+ ions, are accelerated toward the cathode sheath and hit the cathode, with the target material to be deposited placed on it. The target atoms are ejected after the collisions, which are subsequently settled down on the substrate surface, acting as the anode.

DC Sputtering Parameters

A DC sputter deposition process is controlled by several parameters, such as sputtering current and voltage (Sputtering power), ultimate pressure, and working pressure. Adjusting each of these factors affects the sputtering process features, including sputtering rate and deposition rate.

Vac Coat DC sputtering systems enable the user to manipulate the DC sputtering parameters through the user-friendly interface and real-time monitoring on the device’s touch screen.

Main Parts of a DC Sputter Coating System

A DC sputtering system involves different parts, including, sputtering chamber, vacuum system, sputtering cathode, target material, process gas, DC power source, etc.

Supplementary instruments can be added to the sputtering chamber, so as to enhance the coating precision, uniformity, and purity, for example rotating or planetary substrate holder, cathode shutter, film thickness meter, etc.

Vac Coat DC sputtering systems include rotational substrate holders in different sizes to improve the resulting film thickness uniformity. Additionally, all Vac Coat coating systems are supplied with quartz crystal microbalance (QCM) thickness meters to improve deposition accuracy with real-time film thickness measurement. The electronic shutter installed on the Vac Coat sputter coaters in front of the cathode allows cleaning the target material surface prior to initialising the deposition process to obtain a pure coating.

Coating Techniques Based on the DC Sputter Deposition

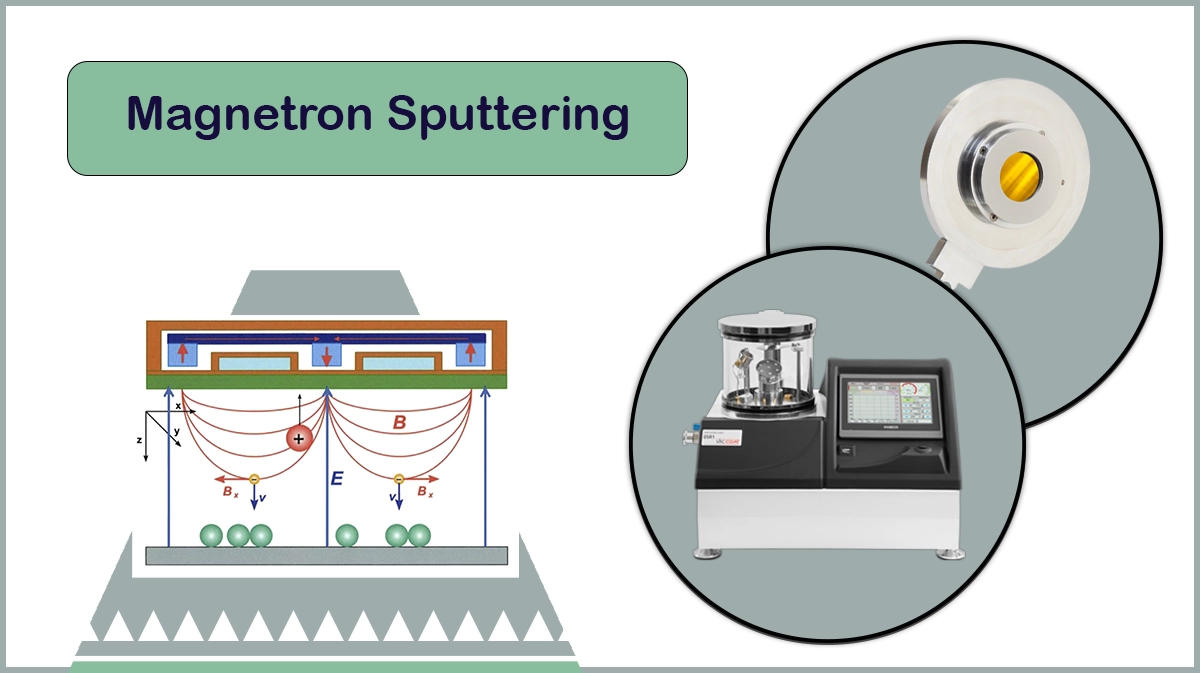

Some techniques are developed to enhance the DC sputter coating parameters, such as Pulsed DC sputtering, DC magnetron sputtering, and reactive sputtering.

DC Sputter Coating Applications

DC sputtering has numerous applications in research and industry. It is an easy method that is frequently used in the creation of a thin conductive layer on electron microscope samples in a fast coating cycle, as in SEM coaters. Also, it is used in the deposition of conductive layers in electronics and integrated circuits.

Creating reflective films, magnetic films, decorative coatings, and transparent conductive films for solar cells are other applications of DC sputter deposition.

Challenges

The DC-diode sputtering process has several limitations, such as limited target material types and sputter deposition rates.

Moreover, the electron-ion collisions in the glow discharge plasma in DC-diode sputtering do not give rise to secondary electron emission, which is desirable in creating a sustainable plasma. Consequently, the ionisation process cannot be scaled up by increasing the DC sputtering power.

DC Sputtering in Our Products

In this article, different aspects of DC sputter deposition, instrumentation, and applications are discussed. DC sputter coating is a promising method for deposition of various coatings with applications in diverse fields.

Vac Coat Ltd. offers various low-vacuum and high-vacuum sputter coaters with single or multiple cathodes, such as DSR1, DST1, DST2-TG, and DST3, that are able to perform DC sputtering deposition with precise control over chamber pressure, cathode temperature, coating thickness, and empowering automatic and reliable coating processes with reproducible results.

Some of Vac Coat's Products

References

- Ohring, M. (2001). Materials Science of Thin Films (2nd ed.). Academic Press

- Gobbi, Angelo L., and Pedro AP Nascente. “DC Sputtering.” Encyclopedia of Tribology. Springer, Boston, MA, 2013. 699-706.

- Adachi, H., & Wasa, K. (2012). Thin films and nanomaterials. In Handbook of Sputtering Technology (pp. 3-39). William Andrew Publishing.

- Garg, R., Gonuguntla, S., Sk, S., Iqbal, M. S., Dada, A. O., Pal, U., & Ahmadipour, M. (2024). Sputtering thin films: Materials, applications, challenges and future directions. Advances in colloid and interface science, 330, 103203.

- Simon, Andrew H. “Sputter processing.” Handbook of thin film deposition. Elsevier, 2025. 93-140.