Vac Coat Company as an innovative designer and manufacturer of vacuum coaters, has upgraded two of its popular sputter coaters for SEM sample preparation and further applications, DSR1 and DST1, with the water-cooled cathode.

DSR1 (low vacuum) and DST1 (high vacuum) models are ideal SEM coaters used for SEM/FESEM sample preparation, where low-duration depositions with film thicknesses in the range of nanometers are required (You can read more about our sputter coaters here).

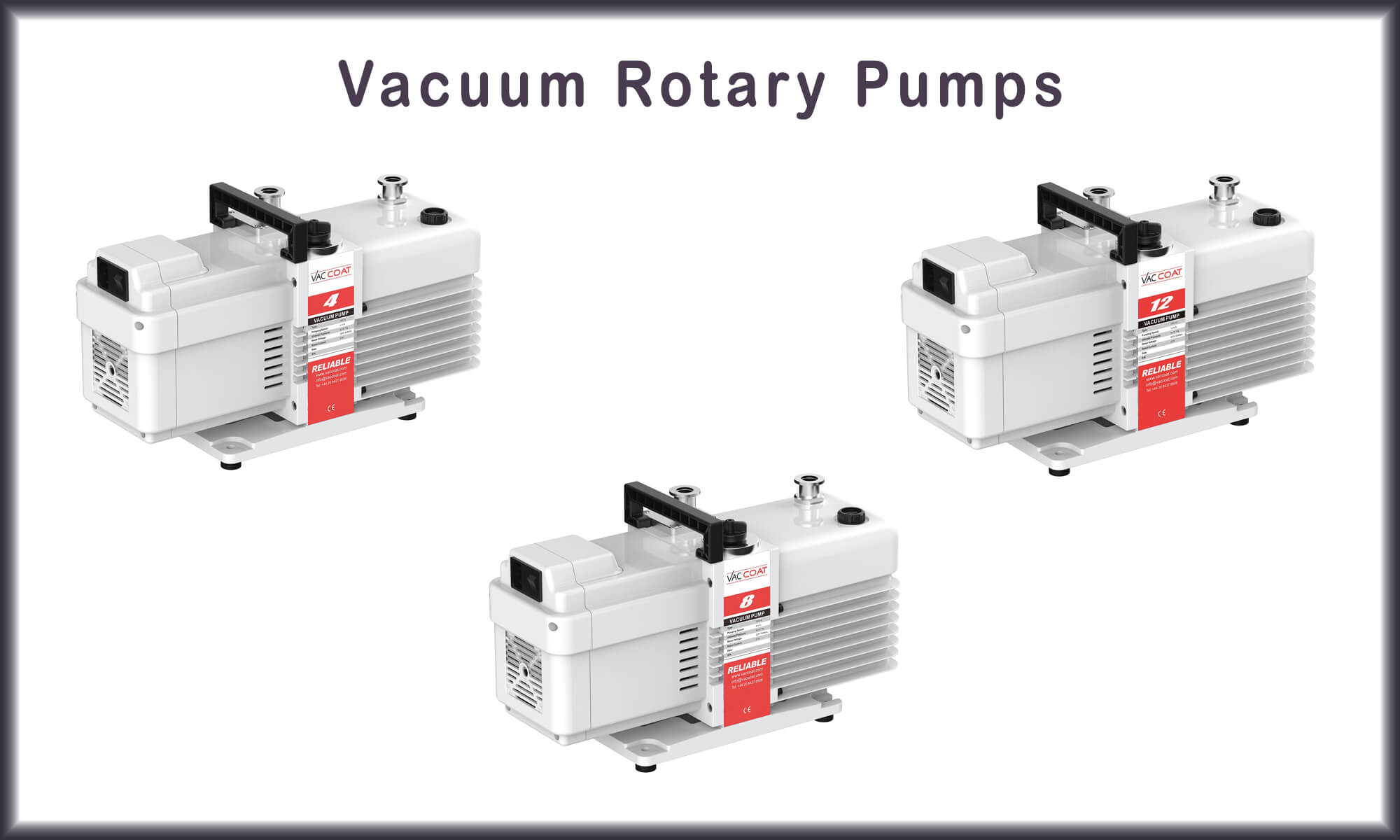

DSR1 sputter coater can be vacuumed with a rotary vacuum pump, hence suitable for non-oxidizing metal (like gold, platinum, silver, etc.) deposition, while DST1 turbo-pump sputter coater is a proper choice for deposition of oxidizing metals (like tungsten and chromium) as well as non-oxidizing.

Typically, SEM samples need a brief (max. 15 min) nanometer-sized coating. However, in case the researchers need to deposit thicker films, depending on the material (for example more than 150 nm Au, or more than 30 nm Cr), the water-cooled cathode is vital to prevent cathode heating during a long-term coating process.

Vac Coat has upgraded the DSR1 and DST1 desktop sputter coaters with a water-cooled cathode to allow unlimited deposition time with these models. Previously, DSR1 and DST1 models were only applicable for short-term thin-layer deposition to prevent cathode and chamber heating. Now, in the new design, this limitation is overcome by utilizing a water-cooled cathode allowing water circulation to cool down the cathode. The user can choose DSR1/DST1 with a water-cooled cathode when placing the order.