Glow Discharge Plasma Cleaning

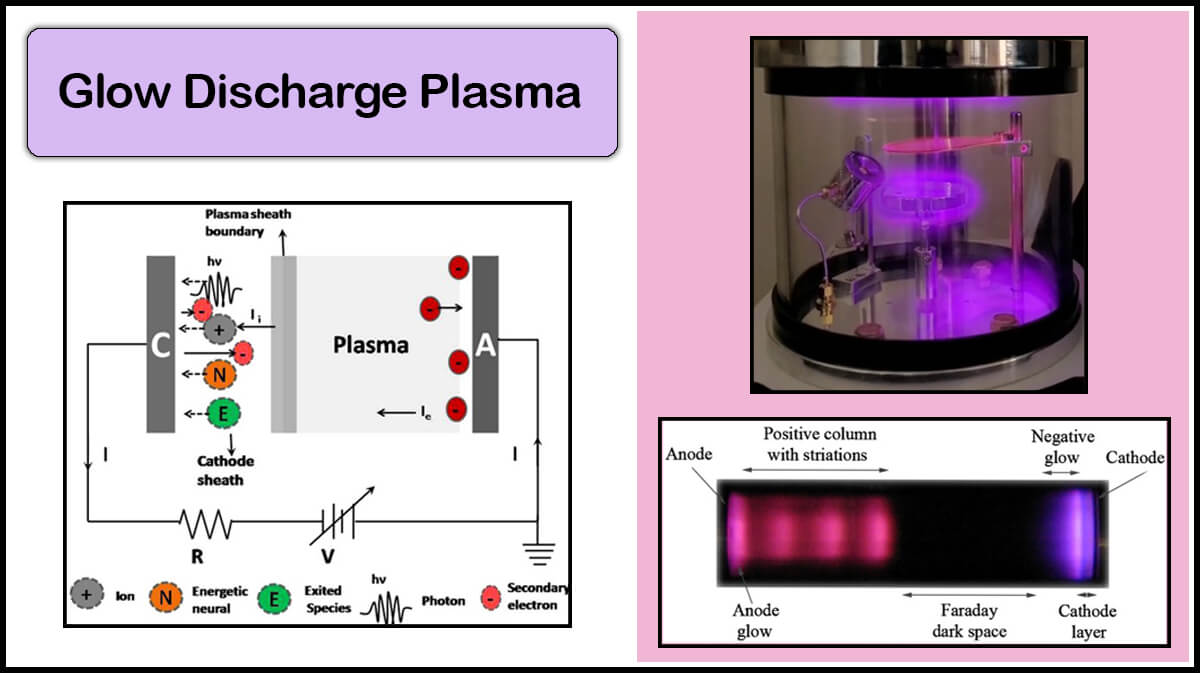

Plasma created by the electric discharge of a gas between two electrodes in a low-pressure chamber is called glow discharge plasma. Glow discharge happens when free plasma electrons recombines with positive ions and emit photons. This phenomenon lies between the dark discharge region with low current ionization and no light emission, and arc discharge with large radiations (Figure 1). Glow discharge plasma contains energetic ionized gases species, which can be used for different purposes, cleaning a surface or coating it, as sputtering deposition method.

DC Glow Discharge Plasma Formation

The subsequent collisions between gas species, like electrons, ions, and neutral atoms between two electrodes result in electrical discharge and breakdown. Electron mean free path in the plasma chamber plays an important role in the amount of energy it gain while reaching the anode. Based on the researches, gas type and pressure (p), distance between the electrodes (d), and electrode radius (r) determine the minimum breakdown voltage (Vb).

Vb= f(pd, d/r) Equation (1)

According to equation (1), Vb is related to product of p and d, and the ratio of d/r. Figure 2 depicts the breakdown voltage for different p, d, and r amounts called Paschen curves.

Plasma Color

The color of the plasma is generated through the photon emission process by the excited atoms or molecules to reach a more stable, lower energy state. The color of the plasma is determined by the photons wavelength, which depends on the atomic/molecular energy bands and is strongly correlated to the gas type and its purity. Moreover, highly contaminated surfaces create plasma arcs during the glow discharge cleaning.

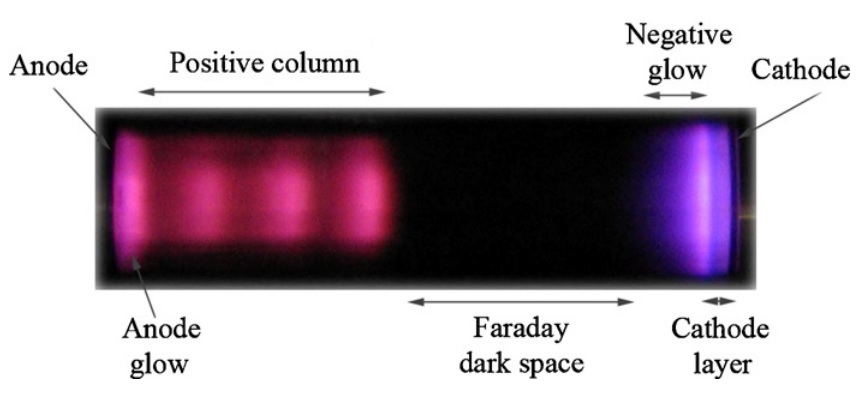

Parts of a Glow discharge Plasma

A glow discharge plasma mainly includes several parts as depicted in figure 3:

- Cathode layer with a positive space charge reduces in enhanced gas pressures

- Negative glow is a region of high density slow electrons easily recombined with positive ions to generate photons

- Faraday dark space is created by the low energy electrons from the previous region, leading to fewer photon emissions

- Positive column is part of the Anode layer with negative space charge and fewer ions. The electrons with energy of about 2 eV can excite atoms and emit light photons. Longer tubes have a longer positive column

- Anode glow is generated because of enhanced electric field

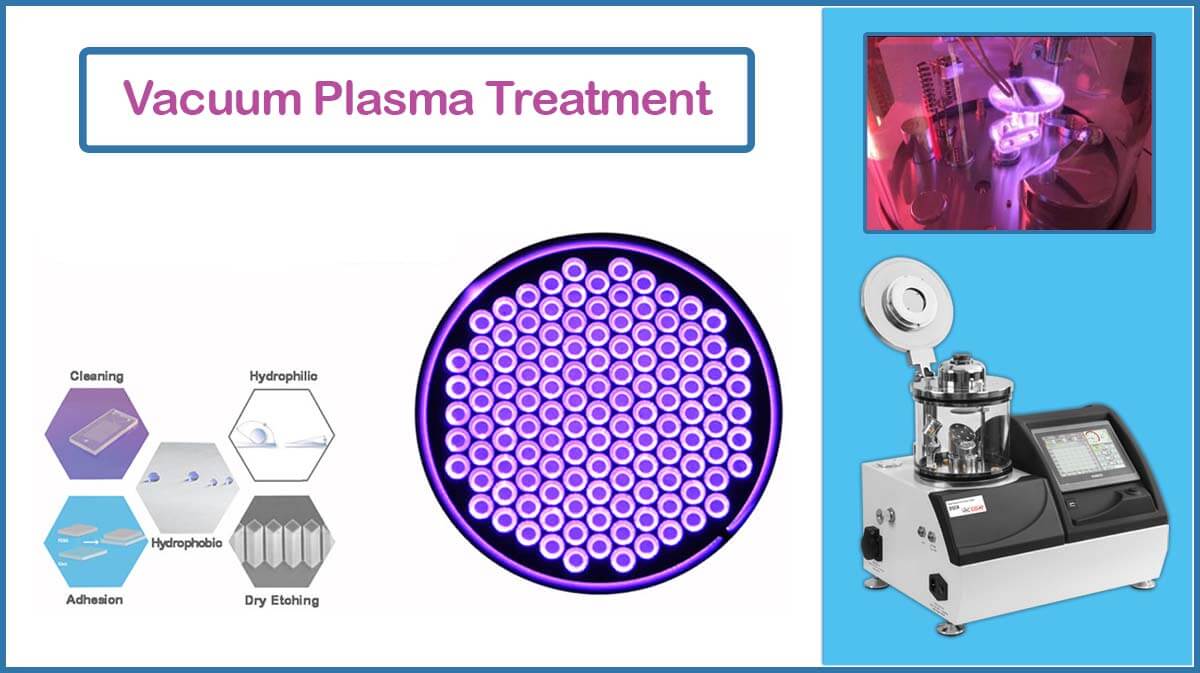

Applications of Glow Discharge Plasma Treatment

Glow discharge plasma contains energetic electrons and ions and generate photons, so can be utilized in different areas. The energetic ions can be manipulated for different applications:

- Light source: Neon plasma lights, plasma-screen TVs, and fluorescent lamps are widely used in everyday life

- Plasma Cleaning: Plasma ions act like a sandpaper on a surface to clean it from contaminations

- Plasma Coating: Sputtering of a targeted cathode to deposit its atoms/molecules on a substrate

- Plasma Activation: By introducing different gas plasmas on a surface it can be modified by functional groups to improve surface adhesion or hydrophilicity/hydrophobicity properties

Vac Coat Vacuum Plasma Coaters and Cleaners

Vac Coat Ltd. is a manufacturer of vacuum coaters with plasma cleaner option for substrate treatments before deposition. Also, TEM grids usually need plasma treatment before imaging.

The Desk Sputter Coaters (DSR1 and DST1), Desk Carbon Coaters (DCR and DCT), and Desk Sputter and Carbon Coaters (DSCR and DSCT) are popular SEM Coaters for SEM and TEM sample preparation. These models are able to hydrophilize carbon support film using air gas in less than 10 minutes. This process is run by a DC electric field, usually in 25 mA current.

Notably, the plasma cleaning in our Vacuum Coating Systems is provided with a self-protection option. After a maximum of 30 minutes operation (normally enough time for the hydrophilization or cleaning process), plasma cleaner stops working and can be activated after a 15-minute time interval if required, to prevent any damage to the device. This time will show as a reverse counter on the plasma cleaner window.

You could find the plasma cleaning option in almost all Vac Coat Products such as DSR1, DST1, Desk Sputter & Carbon Coater – DSCR, Turbo Pumped Sputter & Carbon Coater – DSCT, as well as large chamber models like DST3 and DTT.

References

- https://www.plasma.com/en/plasma-technology-glossary/colour-of-the-plasma/

- https://en.wikipedia.org/wiki/Glow_discharge

- Lisovskiy, V. A., et al. “Validating the Goldstein–Wehner law for the stratified positive column of dc discharge in an undergraduate laboratory.” European journal of physics 33.6 (2012): 1537.

- Arumugam, Saravanan, Prince Alex, and Suraj Kumar Sinha. “Effective secondary electron emission coefficient in DC abnormal glow discharge plasmas.” Physics of Plasmas 24.11 (2017).

- Betti, Maria, and L. Aldave de las Heras. “Glow discharge mass spectrometry in nuclear research.” Spectroscopy Europe 15.3 (2003): 15-24.

- https://web.physics.ucsb.edu/~lecturedemonstrations/Composer/Pages/88.03.html

- Mathew, Prijil, et al. “Experimental verification of modified Paschen’s law in DC glow discharge argon plasma.” AIP Advances 9.2 (2019).