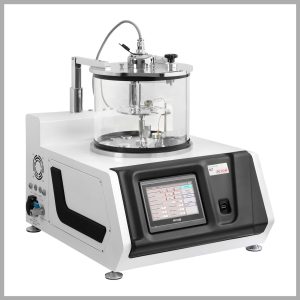

Vac Coat Company, the manufacturer of hi-tech research-grade vacuum coating systems, has designed and produces a new high-vacuum carbon coater and thermal evaporator with a large 300 mm Dia. borosilicate chamber.

Carbon coater and thermal evaporator are now available in a one-compact large chamber deposition system, which facilitates coating thin films on large (Up to 15 cm Dia.) substrates.

This carbon coating system can be provided with carbon fiber (Thread) or/and carbon rod evaporation heads with the appropriate power sources to enable semi/full-automatic programmable carbon depositions in different flash, pulsed, or ramped (For carbon rod) modes, model DCT-300. This coating device can also be provided with a thermal evaporation head containing one thermal source allowing thermal evaporation of materials with low melting point, model DCT-T-300.

The thermal evaporator head is fitted with two electrode extensions to position the thermal source at the desired distance to the substrate and several S-clip substrate holders on the head toward the thermal source for upward thermal vapor deposition. The thermal evaporator can also be fitted with a rotatable sample holder stage on the chamber’s base for downward deposition, similar to the carbon coater configuration.

Vac Coat SEM coaters, like sputter coaters, carbon coaters, and thermal evaporators are ideal coating machines for electron microscope sample preparation. Vac Coat also offers multi-coating systems for multilayer thin film deposition, such as triple source thermal evaporator (DTT), triple-target sputter coater (DST3) with thermal evaporator (DST3-T), and double-target with thermal evaporator for glove box (DST2-TG) that can be fitted into a glove box for more environment-sensitive deposition, as in battery-related applications.