Importance of SEM Aperture Cleaning

Pollutions and contaminations are common problems of electron microscopy (EM) vacuum chambers since they are exposed to different samples containing hydrocarbons or polymeric materials. Microscope apertures that are used to align electron beams are important parts of electron microscopy and their contamination may lead to electric charging and beam deflections, resulting in poor-quality imaging. Cleaning electron microscope apertures can be done by thermal evaporation of the impurities or through the plasma cleaning process.

What is the Role of Aperture in An Electron Microscope?

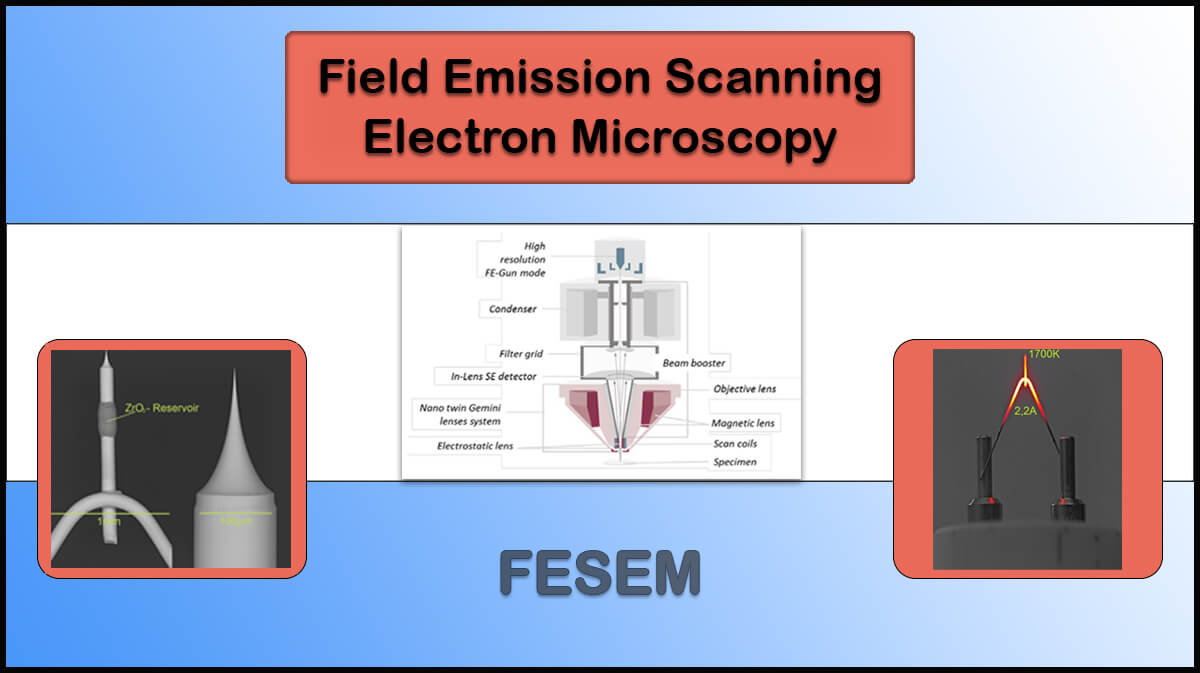

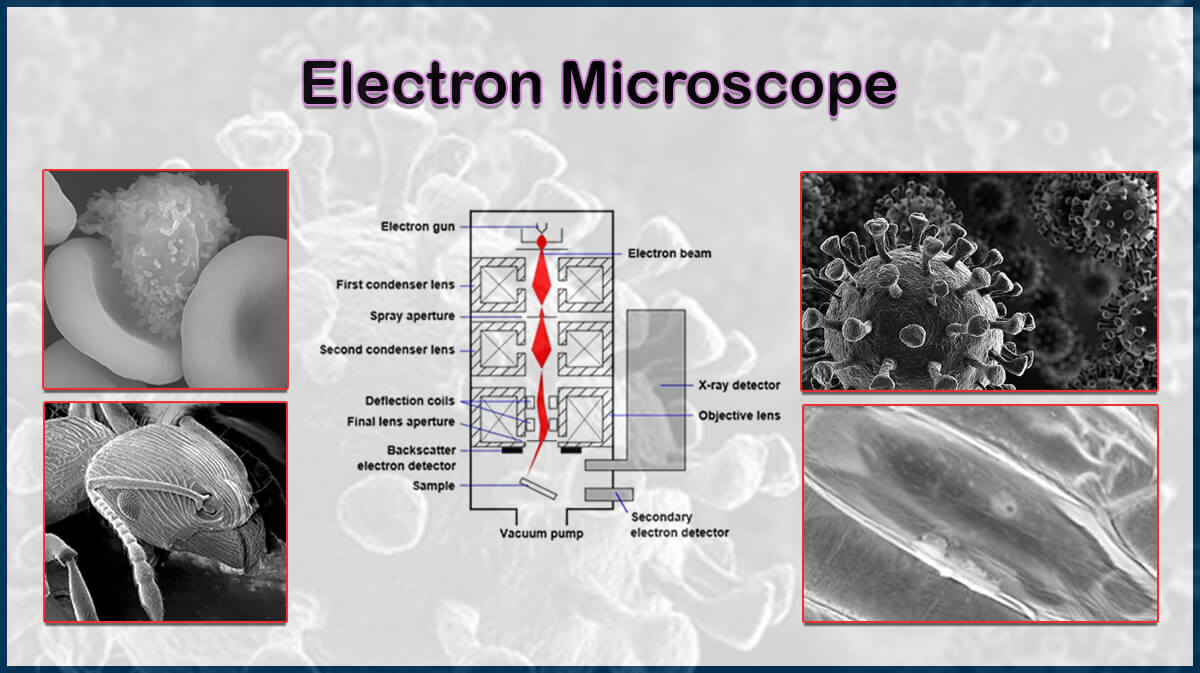

Microprobe systems, including scanning or transmission electron microscopes (SEM, FESEM, or TEM) utilize apertures in several parts including condenser apertures to form electron beam columns and limiting or objective apertures to form an image with higher resolution. The electron beam diameter and focus can be controlled through electromagnetic lenses and apertures.

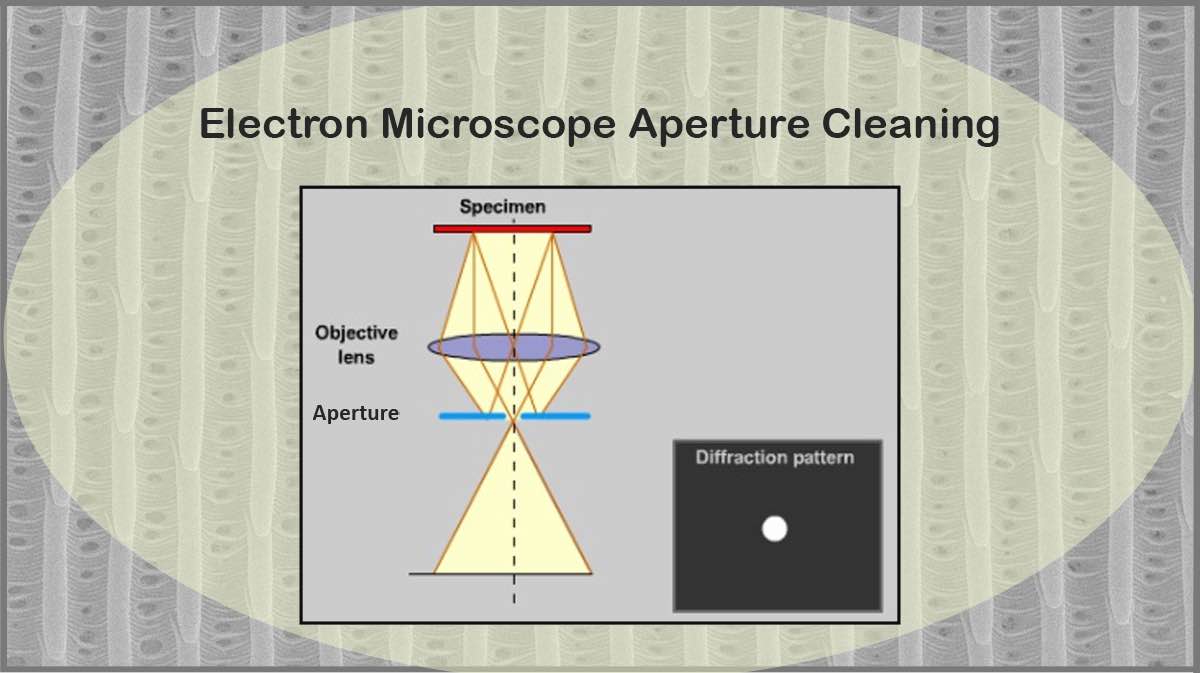

An aperture is a tiny hole in a metal strip (Figure 1) placed in the way of the electron beam to block off-axis or off-energy electrons in the microscope column. The size of the aperture hole determines the beam confinement passing the aperture.

The smaller the aperture, the narrower the electron beam passes through them, leading to a smaller convergence angle and a more parallel beam (Figure 2). Accordingly, a contaminated electron microscope aperture may lead to a distorted image, hence, SEM aperture cleaning is vital for a good image result.

Electron Microscopy Apertures: Types and Uses

The apertures used in electron microscopy are placed in different positions and play various roles. The condenser aperture, objective aperture, and phase contrast apertures are the ones that are discussed here.

Condenser Aperture

The condenser aperture enables the user to limit the fraction of the electron beam colliding with the specimen to adjust the illuminated area of the sample, called spot size, as well as the convergence of the beam at the specimen. The illumination intensity, which controls the depth of field in SEM imaging, also increases with the aperture’s angle, while reducing image quality.

Also, the X-rays emitted from the electrons’ collision with the microscope column can be reduced using the aperture.

Objective Aperture

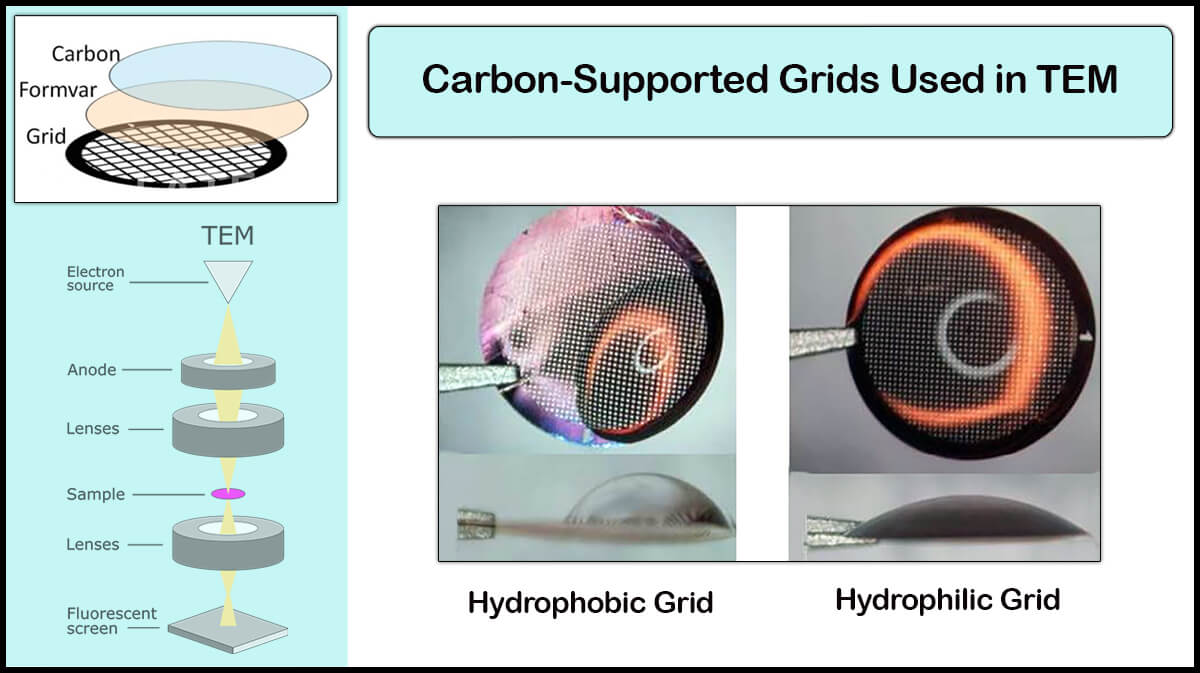

The objective aperture in electron microscopy is located in the back focal plane of the objective lens. In Transmission Electron Microscopy (TEM), the sample under study is positioned between the electron beam source and the objective lens aperture, so the primary role of the aperture is to eliminate the non-diffracted transmitted (000) beam, along with the reduction of the extraneous electrons.

Choosing the right aperture diameter results in eliminating irrelevant scattered electrons and achieving high-resolution secondary electron images. The main duty of the objective aperture is to improve the contrast of the image by selecting the electrons contributing to the image.

Large Aperture vs. Small Aperture

Large apertures are suitable for increasing the signal in low-magnification imaging, as well as backscatter electron (BSE) imaging and microanalysis, whereas smaller apertures are ideal for high-resolution imaging and enhanced depth of focus.

It should be noted that small apertures restrict the number of electrons which reduces the image brightness. The declined intensity occurs due to the aperture size reduction, which has a smaller dependence on condenser aperture size than on objective aperture size. We will discuss the effect of the aperture size on the image resolution later in the Aperture’s Features section.

Phase-Contrast Apertures

Phase-contrast apertures are plates that can change the incident electron waves on them. The relative phase change created between the transmitted and scattered waves from the specimen by placing the phase plate at the back focal plane of an EM results in a change in the intensity of different parts of the image of an object. This technique provides higher contrast imaging of biological samples.

One of the phase plates that are used nowadays is the Zernike phase plate. This phase plate is made of a thin film of carbon with a controlled thickness having a hole at the center, which is made by the manual transfer of the evaporated carbon film to the aperture through floating on the water’s surface.

Phase plate apertures are often coated with a thin film of carbon or gold to cover up contaminants introduced in manual carbon layer transfer, and ensure a uniform electrostatic potential at the surface. Vac Coat Ltd. produces high-precision desk automatic carbon coaters (DCR and DCT), sputter coaters (DSR1 and DST1), as well as hybrid sputter and carbon coaters (DSCR and DSCT) with small or large chambers and various optional features and sample holder stages.

Aperture’s Features

The shape and size of the aperture can affect the image resolution and contrast by controlling the angular range of signals. The Wehnelt aperture is widely used and usually negatively biased according to the emitter to form a repelling electrostatic force that restricts electron emission from the cathode.

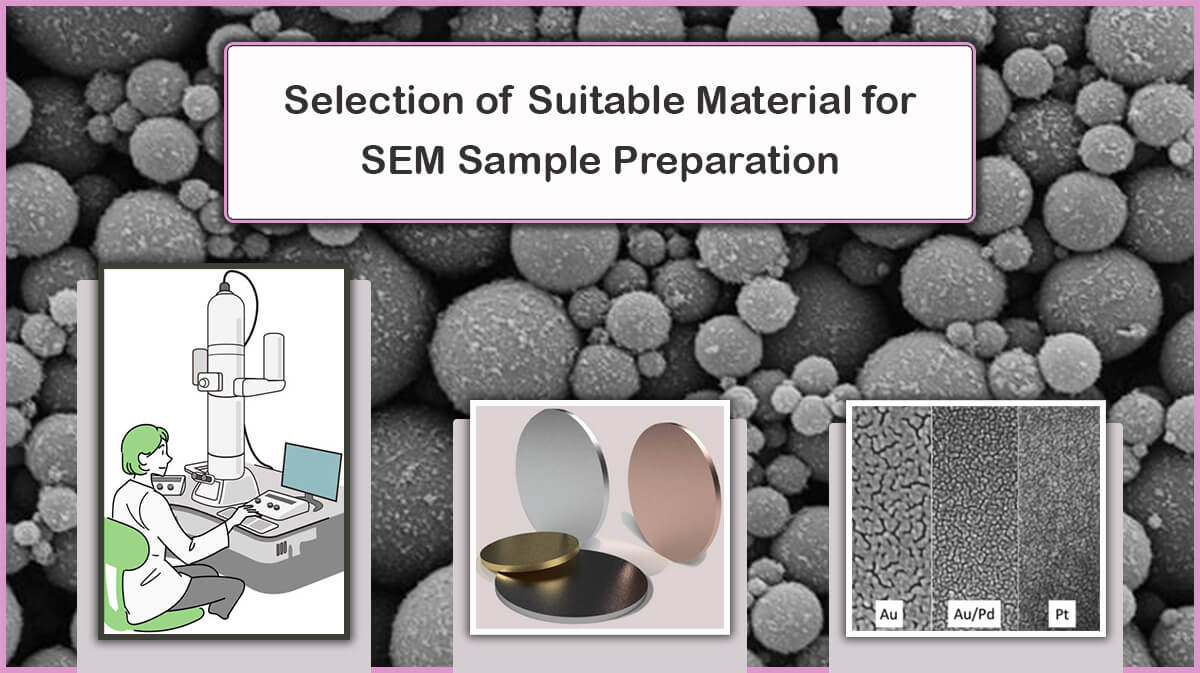

The apertures are available in different compositions, such as Pt/Ir (95:5%), or Mo and Au, with holes smaller than 10µm.

Aperture hole diameter has a significant influence on the image quality. Due to Abbe’s equation, the diffraction-limited resolution in an optical system can be mathematically described by this equation:

d = (0.612 × λ)/(n sinα)

Where d is the resolution, λ is the wavelength of imaging radiation, n is the index of refraction of emission medium relative to free space, and α is half the angle of the cone of light from the sample plane accepted by the objective (Half aperture angle in radians). The phrase “n sinα” is often mentioned as numerical aperture (NA).

According to the wave-particle duality of electrons, they behave as waves when passing through an aperture with a wavelength equal to

λ = h/(m×v)

Here, h is the Planck’s constant (6.6 X 10-27), m is the electron mass (9.1 X 10-28), and v is the velocity of the electrons given by the equation eV = 1/2 mv2, where eV is the energy of the electrons in Volts.

Given the above formulas, we will have:

λ = (1.23 nm)/V^(1/2)

Hence for a TEM image resolution, since n=1, and is very small, the resolution limit is expressed by this equation:

d = (0.753 )/(α〖V〗^(1/2))

Cleaning Electron Microscope Apertures: Sources of Aperture Contamination

The contamination of apertures, normally with a thin film of hydrocarbon, can be originated from different sources, however, any contamination results in charging the aperture, which limits its duty time. Also, the pollutions are built up on smaller holes more quickly, leading to dirt charging up and so astigmatism. Subsequently, the apertures require regular aperture cleaning or replacement to maintain the electron microscope functionality.

The aperture contamination is mainly related to organic compounds that are typically found in a vacuum system, like:

- Vacuum pump oil

- Gaskets

- O-rings and lubrication greases used for them

The specimens made up of organic materials can also be a source of contamination. Also, Molybdenum apertures are easily oxidized when kept under atmospheric conditions.

SEM/TEM Aperture Cleaning Procedures

The SEM aperture cleaning procedure can be performed through Thermal Evaporation or Plasma Cleaning.

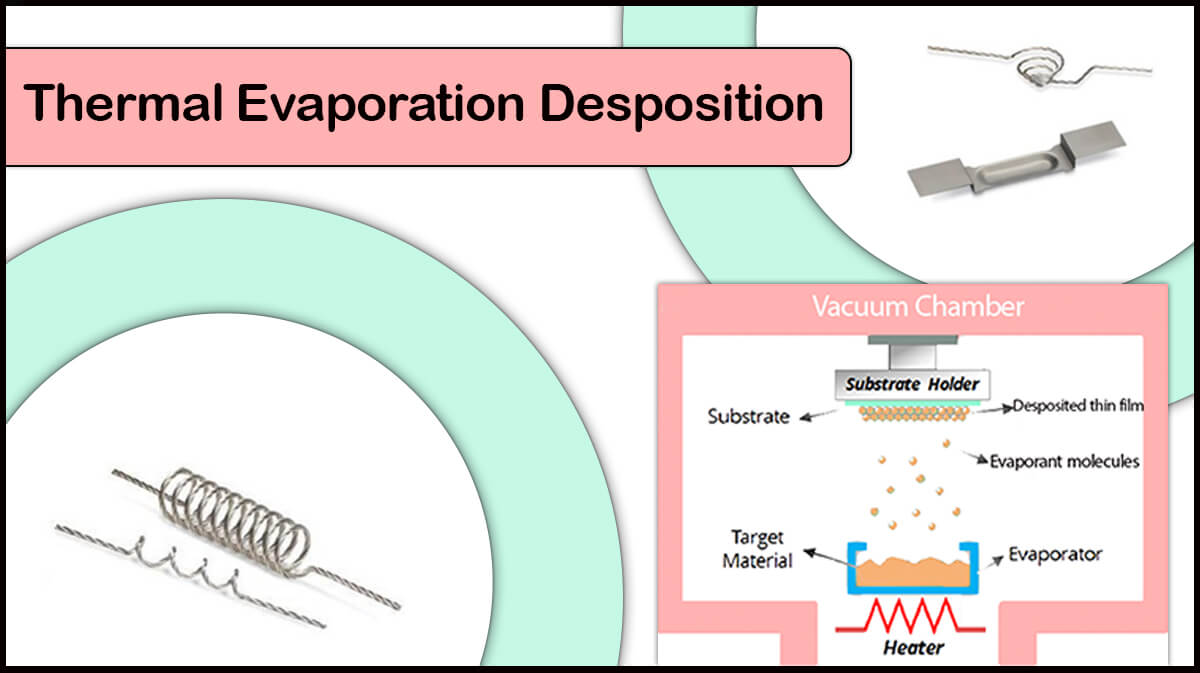

Cleaning Electron Microscope Apertures by Thermal Evaporation Process

Cleaning electron microscope apertures through thermal evaporation is accomplished by heating them to evaporate the unwanted hydrocarbons. However, it should be noted that the color of the aperture should not exceed a red cherry color, and there should not be a temperature gradient over the aperture, otherwise it is deformed and impractical.

The Platinum/Iridium apertures can be flamed or heated in the atmosphere by small flame devices containing alcohol or butane for 10-15 seconds. As previously mentioned, Molybdenum apertures should be heated under high vacuum conditions in a tungsten boat. Mo aperture merit over the Pt/Ir one is its longer lifetime.

Vac Coat vacuum coatings systems like thermal evaporators, DTE and DTT, contain evaporation boats that empower TEM apertures cleaning through thermal evaporation workflow. Hybrid Vac Coat coating systems such as DSCT-T, DCT-T-300, DST2-TG, and DST3-T can also be offered for apertures cleaning by thermal evaporation in electron microscopes.

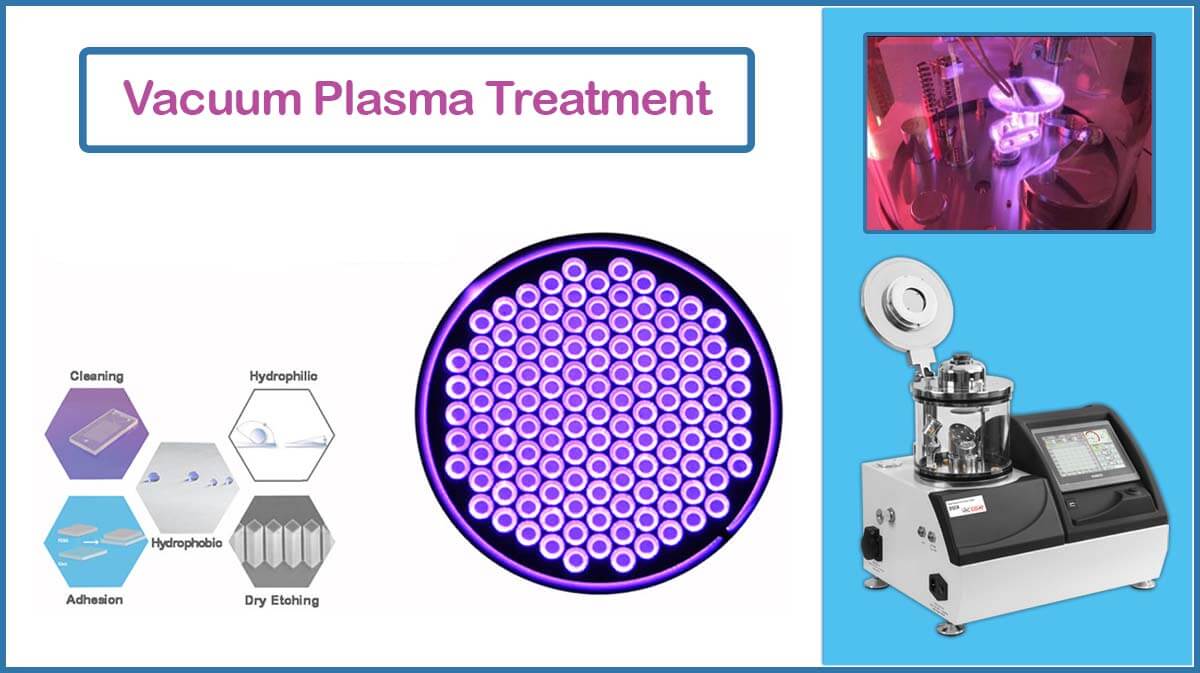

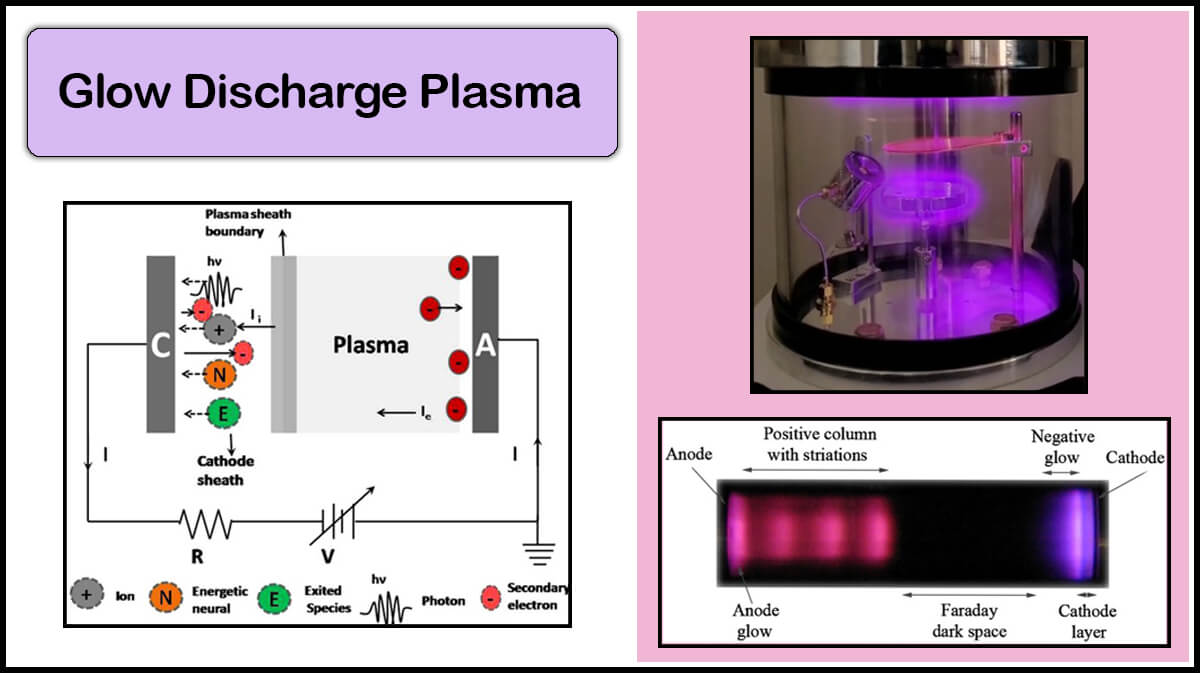

SEM Apertures Cleaning by Plasma Discharge

Cleaning electron microscope apertures by glow discharge plasma is another way to have a clean aperture. The plasma cleaning process can remove hydrocarbon contaminations. Plasma treatment on a surface includes bombarding it with high-energy ions that can remove most surface contaminations and/or create desired surface properties.

Almost all Vac Coat vacuum coaters can be equipped with glow discharge plasma rod that enables plasma treatment. Also, the plasma can be applied to the shutter to enhance the plasma treatment effectiveness in sputter coaters.

Some of Vac Coat Systems

References

- https://www.sciencedirect.com/topics/engineering/objectiveaperture#:~:text=In%20TEM%2C%20the%20specimen%20is,creating%20a%20conventional%20DF%20image

- https://myscope.training/SEM_Apertures

- https://www.tedpella.com

- https://web.eng.fiu.edu/

- https://www.ou.edu/research/electron/bmz5364/resolutn.html

- Moore, K. T., Howe, J. M., Veblen, D. R., Murray, T. M., & Stach, E. A. (1999). Analysis of electron intensity as a function of aperture size in energy-filtered transmission electron microscope imaging. Ultramicroscopy, 80(3), 221-236.

- https://iubemcenter.indiana.edu/

- https://www.emsdiasum.com/apertures-and-aperture-cleaning

- https://en.wikipedia.org/wiki/Wehnelt_cylinder

- Practical Electron Microscopy and Database (online book): Contamination of apertures (globalsino.com)

- Glaeser, Robert M. “Invited Review Article: Methods for imaging weak-phase objects in electron microscopy.” Review of Scientific Instruments 84.11 (2013).

- Danev, Radostin, and Kuniaki Nagayama. “Phase plates for transmission electron microscopy.” Methods in enzymology. Vol. 481. Academic Press, 2010. 343-369.

- https://www.jeol.com/