What is Pulsed Laser Deposition (PLD)?

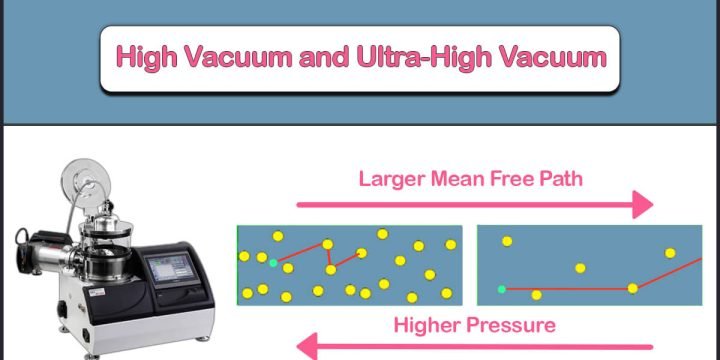

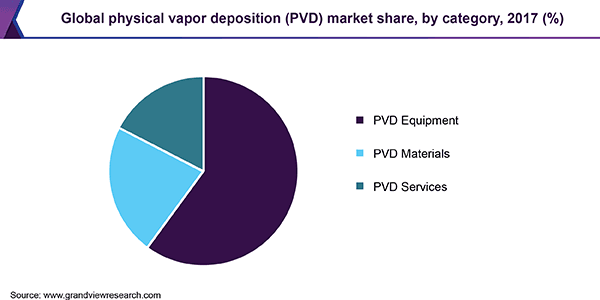

[vc_row][vc_column width="3/4"][vc_row_inner][vc_column_inner][vc_column_text] An Overview of Pulsed Laser Deposition Pulsed laser deposition is a physical vapor deposition technique in which a high-energy laser is focused on a target material in a vacuum chamber and converted to a plasma plume, which is deposited on a substrate (Figure 1). The deposition can be assisted by a flow of oxygen or other background gases, or occur under ultra-high vacuum conditions. [/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner css=".vc_custom_1715269871382{background-color: #d9d9d9 !important;}"][vc_column_inner width="1/2"][vc_video link="https://youtu.be/JL8qvTW-WCg" align="center"][vc_column_text css=".vc_custom_1715271079446{margin-top: -20px !important;}"] Pulsed Laser Deposition PLD Explained with Animations [/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_cta h2="" txt_align="center" style="3d" color="mulled-wine" el_width="xl" add_button="bottom" btn_title="What Is PVD?" btn_style="3d" btn_color="juicy-pink" btn_align="center" btn_link="url:https%3A%2F%2Fvaccoat.com%2Fblog%2Fphysical-vapor-deposition-pvd%2F|title:Physical%20Vapor%20Deposition%20(PVD)|target:_blank"][/vc_cta][/vc_column_inner][/vc_row_inner][vc_row_inner][vc_column_inner width="1/2"][vc_column_text] While the equipment needed to perform the deposition in this manner is roughly similar to other deposition methods (such as sputtering), the physical interaction between the laser beam and the target…