Thermal Evaporators

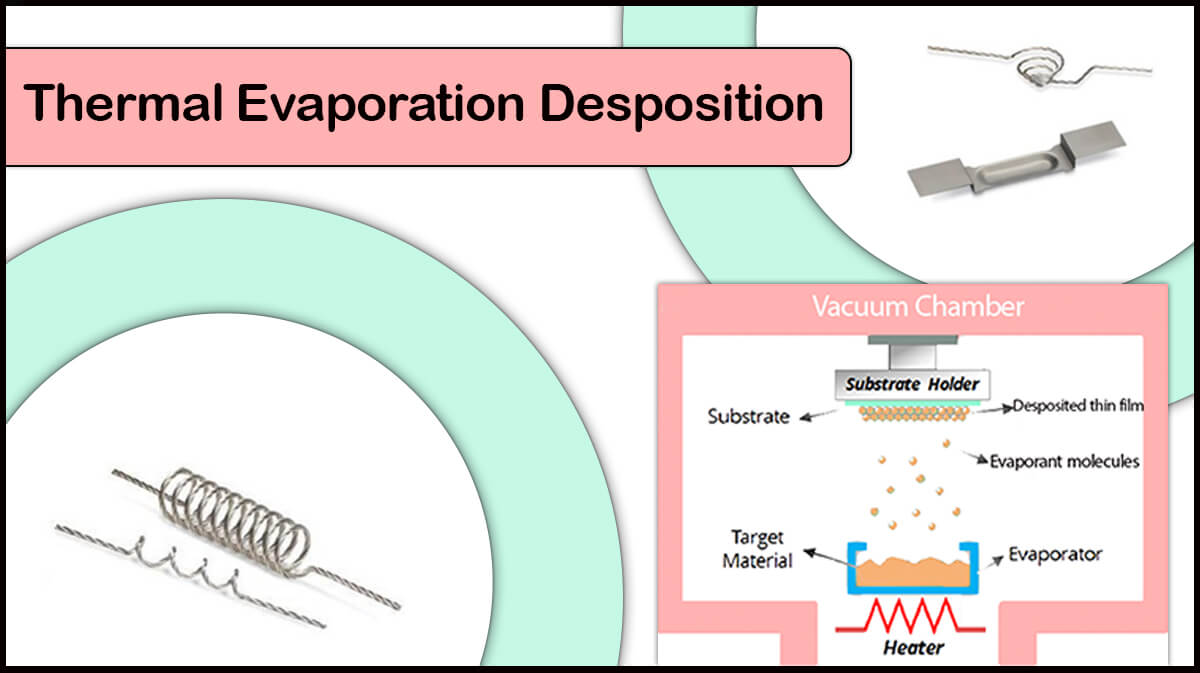

Thin film deposition by thermal evaporation is a physical vapor deposition (PVD) technique for creating thin films of different materials. Thermal evaporation deposition technique is based on thermal heating of the source material in a high-vacuum chamber (pressure < 10-5 Torr), which increases its vapor pressure and leads to the formation of a thin film of the material on the substrate inside the chamber. Vac Coat offers high-vacuum DTE and DTT thermal evaporators optimized for the deposition of different materials’ thin films.

Thermal evaporation systems commonly work through resistive heating of a source holder. The source holders can be in the form of a metallic boat or a basket of refractory wire made of W or Mo covered by aluminum oxide. In the thermal evaporation process the material is evaporated from the boat/basket holder heated by passing a sufficiently high electric current and is deposited on the substrate positioned normally above the sample.

Difference of Thermal Evaporation Systems and Sputter Coaters

The thermal evaporation deposition is rather slow but provides more control over the uniformity and thickness of the deposited thin film compared to other PVD methods, like sputtering or electron-beam evaporation. On the other hand, the melting point of certain materials are so high that resistive heating could not afford enough energy to vaporize them, where other PVD methods could be beneficial.

Vac Coat Thermal Evaporator System

Vac Coat manufactures turbo-pumped thermal evaporators in small and large chambers, DTE and DTT, respectively. DTE is a short-term metal evaporator with a small (170 mm dia.) chamber that can be vacuumed quickly and is an ideal vacuum coating device for SEM sample preparation. The specimen in DTE can be positioned on different substrate holder configurations, above or under the source holder.

The DTT desk thermal evaporator is capable of extended-duration film deposition without any damage to the coating system. Also, DTT can be provided with an extra glass chamber to double the deposition chamber height and improve thin film uniformity and thickness monitoring. DTT, due to its larger 300 mm dia. chamber, is provided with three source holders, suitable for co-evaporation and alloying (optional extra power sources are required). DTT can also be delivered with a substrate cooling holder and glove box installation interface as optional hardware features.

The Rest of Our Thermal Evaporation Systems

Vac Coat also offers hybrid coating systems with thermal evaporators, as desk sputter/carbon coater with thermal evaporator, DSCT-T, desk large chamber carbon coater and thermal evaporator, DCT-T-300, the triple-cathode desk sputter coater with thermal evaporator, DST3-T, designed for multi-purpose applications and innovative double-target turbo-pumped sputter coater and thermal evaporator, glove box compatible DST2-TG, with interchangeable deposition sources up to maximum three sources.

Moreover, Vac Coat pulsed laser deposition system, the so-called PLD-T coating machine, is also provided with thermal evaporation ability.

Can Vac Coat’s thermal evaporators be integrated into glovebox systems?

Yes, certain models like the DTT can be installed inside a glovebox, allowing for the deposition of air-sensitive materials in a controlled environment.

What features enhance the performance of Vac Coat’s thermal evaporators?

“Key features include:

High-current DC power supply: Ensures efficient heating of evaporation sources.

Turbomolecular pump: Provides a clean, high-vacuum environment for deposition.

Quartz crystal monitoring system: Allows real-time thickness measurement with 1 nm precision.

Adjustable substrate holder: Facilitates precise control over deposition parameters.”

How does thermal evaporation differ from sputter coating?

Thermal evaporation typically offers more control over the uniformity and thickness of the deposited thin film compared to sputter coating. However, it may be slower and less suitable for materials with very high melting points, where sputtering or other PVD methods might be more effective.

What are the typical applications of Vac Coat’s thermal evaporators?

“These systems are commonly used in:

Fabrication of thin film sensors

Production of optical components

Nano and microelectronic device fabrication

Solar cell manufacturing

Lithium battery fabrication

Deposition of metal thin films”

What types of thermal evaporators does Vac Coat offer?

“Vac Coat provides several thermal evaporator models, including:

Desk Thermal Evaporator (DTT): A desktop, turbomolecular-pumped system ideal for multilayer or alloy thin film deposition.

High Vacuum Thermal Evaporator (DTE): A compact system designed for depositing thin layers of materials, suitable for research purposes and electron microscopy sample preparation. “