Reactive Sputtering: A Brief Overview and Advantages

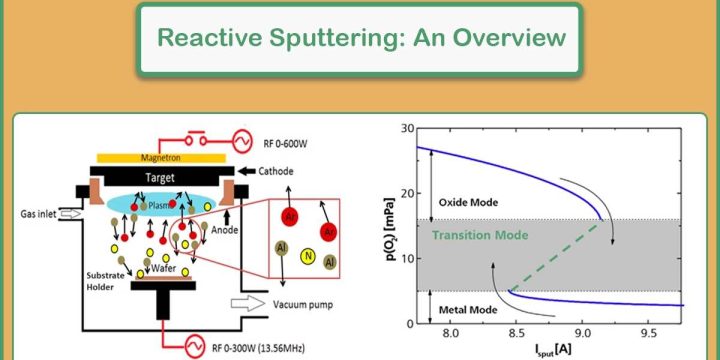

[vc_row][vc_column width="3/4"][vc_row_inner][vc_column_inner][vc_column_text css=""] Reactive Sputtering: Principles, Properties, Applications, and Challenges Reactive sputtering is a versatile physical vapor deposition (PVD) technique employed in the sputter deposition of compound thin films by introducing reactive gases into the sputtering chamber. This article provides a detailed overview of the reactive sputtering process, including its underlying principles, operational modes, advantages, challenges, and diverse applications across various industries. The article also delves into the critical parameters influencing the reactive sputtering process within a sputter coater, such as gas flow rates, pressure, and sputter power, along with strategies for optimizing film properties and addressing common issues like target poisoning and hysteresis effects. [/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner css=".vc_custom_1717000975045{background-color: #d9d9d9 !important;}"][vc_column_inner width="1/2"][vc_cta h2="" txt_align="center" style="3d" color="mulled-wine" add_button="bottom" btn_title="More About Sputtering" btn_style="3d" btn_color="juicy-pink" btn_align="center" css="" btn_link="url:https%3A%2F%2Fvaccoat.com%2Fblog%2Fsputtering%2F|title:Sputtering%20Process%20%7C%20Sputtering%20Deposition%20Method|target:_blank"][/vc_cta][/vc_column_inner][vc_column_inner width="1/2"][vc_video link="https://youtu.be/TSpTqmIqglE?si=uriXsW92DSbf8l7X" css=""][vc_column_text css=".vc_custom_1735569121646{margin-top: -20px !important;}"] Sputtering…