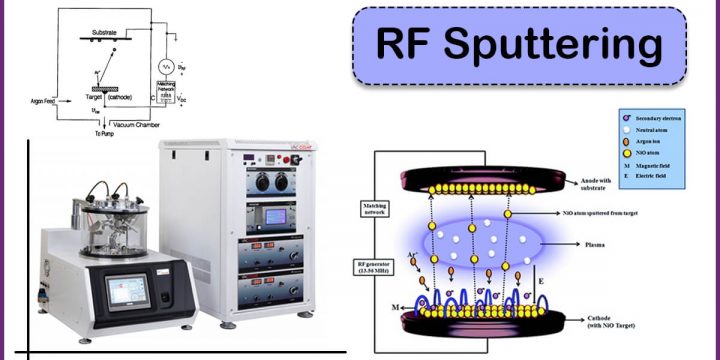

What is RF Sputtering? | DC vs RF Sputtering

[vc_row][vc_column width="3/4"][vc_row_inner][vc_column_inner width="1/2"][vc_column_text css=""] Why RF Magnetron Sputtering? Direct current (DC) sputtering is a cost-effective method for thin layer deposition of electrically conductive metallic targets. But this method is not applicable for non-conductive dielectric target materials, since bombarding such targets with positive ions causes charging the surface of the target, which repels further positive ion bombarding the surface, resulting in the cessation of sputtering process and arcing into the plasma. In order to overcome DC sputtering shortcomings, RF sputtering is widely used for electrically non-conductive target materials deposition. [/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text css=""] [lwptoc backgroundColor="#d6d6d6" borderColor="#5b5b5b" skipHeadingText="References|Recent Posts|RF Sputtering Systems|The Other Sputter Coaters|What is SEM?|FESEM vs SEM"] [/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner css=".vc_custom_1715789177436{background-color: #d9d9d9 !important;}"][vc_column_inner width="1/2"][vc_video link="https://youtu.be/sz5P0D8JZi4?si=i1uuV41yoflsilpK" align="center" css=".vc_custom_1741299405278{border-radius: 2px !important;}"][vc_column_text css=".vc_custom_1741299430011{margin-top: -20px !important;}"] Vac Coat Sputter Coaters [/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_cta h2="" txt_align="center" style="3d" color="mulled-wine" add_button="bottom" btn_title="What…