Versatile Pulsed Laser Deposition and Thermal Evaporator System – PLD-T is a high vacuum thin film deposition system enables to deposit different materials by both Pulsed Laser Deposition and Thermal Evaporation technique (Not Simultaneously). It can deposit complex materials and crystalline structures onto substrates with very little setup involved.

Pulsed Laser Deposition technique leads to efficient, none-thermal ablation and preserves the stoichiometry of the target materials. By applying this method, it could deposit materials such as nitrides, oxides, super lattices, polymers, and composites. PLD-T with triple thermal sources can also deposit thin films through thermal evaporation.

PLD-T physical vapor deposition system is a multi-technique precise thin film coating device that enables the user to perform state of the art research projects in various fields like optics, electronics, solar cell fabrication, etc.

Features

Hardware

- High vacuum level with a built-in turbo pump

- Two-stage rotary vane backing pump (Diaphragm or scroll pump)

- High-current DC power supply suitable for thermal evaporation of different materials

- Quartz crystal monitoring system for real time thickness measurement (1 nm precision)

- Reactive gas injection control through precision Mass Flow meter (MFC)

- Full-range vacuum gauge

- Rotatory sample holder with adjustable rotation, height, and tilt (For 3-inch sample holders)

- Target manipulator with adjustable rotation speed

- 3 thermal sources and special feedthrough

- Equipped with electronic shutter (for thermal evaporation configuration)

- Equipped to motorized boat selection

- Two-year warranty

- Vac coat Products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

Automation

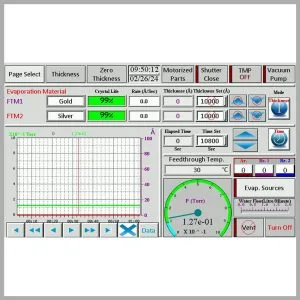

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software, updatable via network

- Semi-full automatic timed or thickness coating process (Optional)

- Deposition parameters adjustable though the touch screen panel (Optional)

- Records and plots coating parameters graphs

Optional Facilities

- 500 °C programmable substrate heater with software control

Target Manipulator

PLD deposition system is equipped with a multi-target manipulator which includes three 2 cm Dia. Targets are in standard size and all of our target manipulators are motorized, so as to enable automatic target selection and target rotation during the deposition process.

Thermal Evaporation

The Pulsed Laser Deposition System can be fitted with three independent heat resistance thermal evaporation sources. Different types of thermal evaporation sources (Boat, basket, and coil) can be installed on the thermal source holders for controlled thermal evaporation of a wide range of materials onto the substrate. The high-current power supply and low-voltage (Resistive) thermal evaporation platform are suitable for a wide variety of thermal evaporation applications. The thermal evaporation configuration is equipped with water-cooled feedthroughs accompanied by temperature sensor.

Thermal Sources Holders

The Pulsed Laser Deposition System can be fitted with three independent heat resistance thermal evaporation sources. The good design of the evaporation source holder causes no contamination transfer from a source materials to other ones. The length of source holders can be adjusted in the range of 5~10 cm to meet the user requirements.

Clean Vacuum

The PLD-T is designed with a 300 mm OD and 200 mm H, SST vacuum chamber. The PLD-T is fitted with an internally mounted turbo molecular pump, backed by a 6 m3/h two-stage rotary vane pump (Optional). It introduces a clean vacuum without oil contamination which normally exists with an ordinary diffusion pump.

Touch Screen Control

The pulsed laser deposition system, PLD-T, is equipped with a 7” colored touch-screen panel using user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touchscreen and the last 300 coatings are saved on the history page.

Specification of Pulsed Laser Deposion & Thermal Evaporator System

- Turbomolecular pump with different pumping speeds (Optional):

Pumping Speed 90 l/s 250 l/s 350 l/s Ultimate Pressure 8 x10-6 Torr 3×10-6 Torr 8×10-7 Torr - Unlimited deposition time without breaking the vacuum

- Records and plots coating parameters graphs

- Deposition process curves and data transfer by a USB port to PC

- 2 kW high-current power supply

- Water-cooled high-current electric feedthroughs

- Utilities: 220 V – 110 V, 50/60 HZ

- Dimensions: 500 mm H × 600 mm W × 470 mm D

- Weight: 50 kg (Pump, , and instrument case)

Applications

- Metal, semiconductor, and dielectric films

- Nano and microelectronic

- Solar cell applications

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

Options and Accessories

The PLD-T has the following options and accessories:

- Thermal evaporation sources (Boat/Basket/Coil)

- 500 °C substrate heater

- Thermal evaporation source materials

- Quartz crystal sensors

- Sealing gaskets

Similar Products

FAQ

PLD Technique Fundamentals

1- What is Pulsed Laser Deposition (PLD) method?

PLD is a technique to deposit thin films by focusing a high-power laser pulse onto a target material (e.g., a ceramic) and vaporizing a small amount of it in the form of a plasma plume, which travels through the vacuum chamber to reach the substrate (e.g., a silicon wafer), where it condenses to form a thin, layered coating.

2- What is the basic setup of a PLD system?

A PLD system typically contains four key components, including:

- Laser:Typically an excimer (KrF, ArF) or Nd:YAG laser.

- Vacuum Chamber:Contains the target and substrate to have a clean deposition.

- Target:The material to be laser-ablated and deposited.

- Substrate Heater:To heat the substrate for growing crystalline films.

3- Why is PLD so popular in research?

The greatest advantage of utilizing PLD technique for thin film deposition is stoichiometric transfer of the target material onto the substrate, which means the film’s chemical composition is very close to the target’s composition. This is crucial for complex materials like high-temperature superconductors (YBa₂Cu₃O₇) and complex oxides.

4- What kinds of materials can be deposited using PLD?

PLD method is widely used in coating various thin films of different materials, such as:

- High-Temperature Superconductors

- Complex Oxides (ferroelectrics, multiferroics, piezoelectrics)

- Dielectrics (SiO₂, HfO₂)

- Nitrides (TiN, GaN)

- Diamond-Like Carbon (DLC) films

- Metals and Semiconductors

- Biomaterials (e.g., hydroxyapatite)

5- What are the advantages of PLD compared to other deposition techniques like Sputtering or MBE?

PLD generally has better stoichiometric transfer for complex oxides compared to sputtering deposition, while sputtering technique benefits in providing thickness uniformity of thin film deposition over larger specimen, and is more established in industry.

MBE technique provides the ultimate control at an atomic level and superior film quality but is much slower, more complex, and far more expensive than PLD.

In general, the PLD technique advantages include:

- Stoichiometric Transfer: Excellent for multi-component materials.

- High Deposition Rate: Relatively fast compared to some other techniques.

- Versatility: Can deposit virtually any material—metals, semiconductors, insulators, polymers—simply by changing the target and using the proper laser.

- Clean Process: The laser is outside the chamber, minimizing contamination.

- Reactive Deposition: Easily done by adding a background gas (e.g., O₂, N₂).

6- What are the main challenges of PLD?

- Droplet Formation: Molten droplets or solid particulates can be ejected from the target and land on the film, creating defects.

- Small Deposition Area:The plasma plume is highly directional, leading to non-uniform thickness over large areas. This makes it less suitable for industrial coating of large wafers.

- Cost:High-power pulsed lasers are expensive to purchase and maintain.

- Film Thickness Uniformity:Requires careful optimization of the target-to-substrate distance and plume dynamics.

7- Why droplets are formed on the substrate in PLD method?

The droplets or particulates generated during the pulsed laser deposition from the target, are caused by subsurface boiling, splashing of molten material, or exfoliation of fragile target material.

The solutions to this problem include:

- Optimizing laser fluence (not too high)

- Using a smooth, polished target

- Rotating the target

- Using off-axis PLD (placing the substrate outside the direct line of sight of the target)

- Using a mechanical velocity filter to block droplets

8- What are the on-axis and off-axis PLD?

- On-Axis: The substrate is placed directly in front of the target plume, giving high growth rates but susceptible to droplet deposition.

- Off-Axis: The substrate is placed facing parallel to the target surface, so the film grows at a lower deposition rate from material that scatters in the gas phase, effectively filtering out droplets, resulting in much smoother films.

PLD Process Features

9- Why a high vacuum chamber is needed?

The higher the ultimate chamber vacuum (base pressure), the more contaminant gases (like O₂, H₂O, N₂) are removed. So the plasma plume can travel to the substrate in a high vacuum chamber without reacting or scattering, leading to a pure film.

10- Why is a background or process gas (like oxygen) sometimes used?

For depositing oxide materials, a background/process oxygen pressure helps to provide the oxygen needed during the deposition process to insure the correct thin film structure and properties and the proper film stoichiometry.

11- How does substrate heating benefit PLD?

Heating the substrate provides thermal energy the arriving atoms to move on the surface or diffuse in the coated film and place in the correct crystal lattice sites, hence forming a high-quality, crystalline film instead of a disordered, amorphous one.

12- What are the key parameters to control in PLD?

The most important PLD parameters include:

- Laser Fluence:Laser energy per unit area on the target. It must be above the “ablation threshold” to create a plasma.

- Substrate Temperature:Critical for the crystallinity of the film.

- Background/process Gas Pressure:Determines the composition, phase, and even the stress of the film.

13- Why does the target need to be rotated during deposition?

Target rotation ensures uniform erosion of the target surface and prevents drilling a single deep pit into the target, which would change the ablation characteristics and create non-uniform particles.