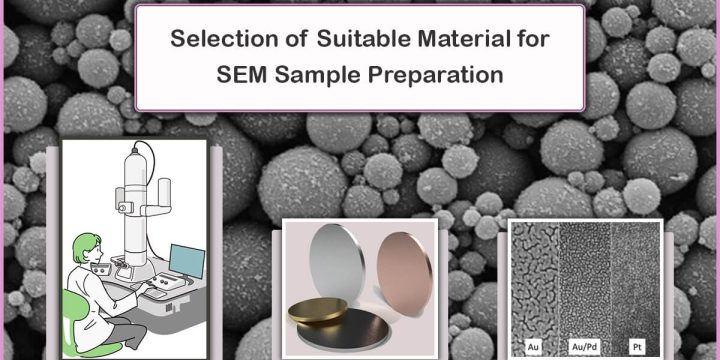

Selection Material for SEM Samples

[vc_row][vc_column width="3/4"][vc_column_text] Selection of Suitable Material for Preparing an Electron Microscope Sample Electron microscopy (EM) is a comprehensive characterization tool to explore micro-nano structures. The samples under study should be prepared before imaging by any type of electron microscopy, namely SEM, FESEM, or TEM. Coating the sample surface with a thin film of proper material, selection material for SEM samples, is one of the well-known preparation steps to achieve high-resolution, clear images. Vac Coat offers various vacuum coaters for SEM sample preparation. [/vc_column_text][vc_row_inner css=".vc_custom_1717954492366{background-color: #d9d9d9 !important;}"][vc_column_inner width="1/2"][vc_cta h2="" txt_align="center" style="3d" color="mulled-wine" el_width="xl" add_button="bottom" btn_title="Electron Microscope" btn_style="3d" btn_color="juicy-pink" btn_align="center" btn_css_animation="rotateInUpRight" btn_link="url:https%3A%2F%2Fvaccoat.com%2Fblog%2Felectron-microscope%2F|title:What%20is%20an%20Electron%20Microscope%3F|target:_blank"] [/vc_cta][/vc_column_inner][vc_column_inner width="1/2"][vc_cta h2="" txt_align="center" style="3d" color="mulled-wine" el_width="xl" add_button="bottom" btn_title="What is FE-SEM?" btn_style="3d" btn_color="juicy-pink" btn_align="center" btn_css_animation="rotateInUpRight" btn_link="url:https%3A%2F%2Fvaccoat.com%2Fblog%2Ffield-emission-scanning-electron-microscopy-fesem%2F|title:Field%20Emission%20Scanning%20Electron%20Microscopy%20(FE-SEM)|target:_blank"][/vc_cta][/vc_column_inner][/vc_row_inner][vc_row_inner][vc_column_inner][vc_column_text css=""] Vac Coat low vacuum sputter coater (DSR1), carbon coaters (DCR), and sputter and…