How Triple Target Sputter Coater DST3-A Works?

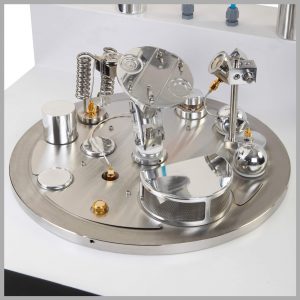

The video represents a brief overview of one of Vac Coat’s sputter coaters. The DST3-A which is shown in this video is a Triple Target Sputter Coater DST3-A equipped with three angled magnetron cathodes with a common focal point. The DST3 is a valuable system to produce fine grain structures because of its independent sputtering control rate for each cathode.

Vac Coat Ltd. has 25-year-old founders and specialists in the design and manufacture of physical vapor deposition (PVD) and vacuum coating systems with high quality and reliability. The company provides laboratory-scale equipment, which is compact. These vacuum coating systems are used in making solar panels, compact hard disks, semiconductor technology, and coating optical lenses and glasses with low emissivity. Over 95% of its customers are universities and research centers.

Designed and manufactured components by our engineering team meet the principal objective of supplying economically priced high-quality vacuum deposition systems. The universities and research centers are the main markets of our vacuum coating systems, which have been sold to distributors worldwide with very good references and feedback. One of the advantages of this knowledge-based company is its highly skilled and expert team of engineers and researchers with well-established academic backgrounds.

Vac Coat’s Sputter Coaters

Several sputter coaters are designed and manufactured by Vac Coat Ltd., including desk sputter coater (DSR1) for SEM samples coating, sputter coater with a thermal evaporator (DST3 & DST3-T), magnetron desk sputter coater (DST1-300 & DST1-170), turbo pumped desk sputter with carbon coater (DSCT & DSCT-T), and desk sputter and carbon coater (DSCR & DSCR-300). In these systems, the sample holder is designed with the ability to rotate and change its angle relative to the position of the cathode.

Triple Target Sputter Coater DST3-A Performance

The DST3 is a triple target sputter coater that has a large chamber with 300 mm diameter and three water-cooled cathodes with 2” diameter. This physical dimension makes it suitable for long-time deposition. This magnetron sputtering system is equipped with RF and DC power supplies. It is suitable for sputtering a variety of targets including semiconductors, dielectrics, and metals. The confocal sputter coater can be done by an auto adjustable matching box which effects in minimizing the reflected power in the RF Sputtering.

The option of applying a 0 to 300 V, DC bias voltage can considerably increase the film adhesion to the substrate and also improve the deposited film structures. According to the type of cathodes used, DST3 is designed in two models: Triple Target Sputter Coater DST3-A (the angled cathodes) and DST3-S (the straight cathodes). The shutters of DST3-A are moved manually and the sample rotation system can place the substrate in front of each cathode. To form alloys or multilayers by this system, you can sputter from two or three targets simultaneously or independently.

Moreover, to protect the lifetime of the magnets and to control safely the cathode’s temperatures, each cathode is monitored by a thermal sensor and automatically will shut off the power supplies if the temperature of the cathodes rises too high. In addition, this device has two MFCs with 1 sccm gas adjustment precision and another electronic flowmeter monitors the water flow of the cathodes. The sample can be placed between two cathodes, and both can be activated simultaneously.

Applications

- Metal, Semiconductor and Dielectric Films

- Nano & Microelectronic

- Solar Cell applications

- Co-Sputtering processes

- Glad Sputtering

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

- Fine grain structural deposition for SEM & FE-SEM sample preparation

Applications

- Metal, Semiconductor and Dielectric Films

- Nano & Microelectronic

- Solar Cell applications

- Co-Sputtering processes

- Glad Sputtering

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

- Fine grain structural deposition for SEM & FE-SEM sample preparation

Applications

- Metal, Semiconductor and Dielectric Films

- Nano & Microelectronic

- Solar Cell applications

- Co-Sputtering processes

- Glad Sputtering

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

- Fine grain structural deposition for SEM & FE-SEM sample preparation

Applications

- Metal, Semiconductor and Dielectric Films

- Nano & Microelectronic

- Solar Cell applications

- Co-Sputtering processes

- Glad Sputtering

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

- Fine grain structural deposition for SEM & FE-SEM sample preparation

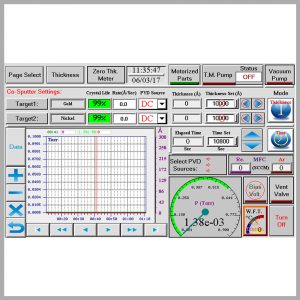

The pressure inside the vacuum chamber can be precisely adjusted by increasing the amount of argon injected into the chamber. The pressure and thickness scale changes automatically according to the changes in pressure and thickness. The power supply can be turned on, provided that all the necessary conditions in the software checklist are ready. By default, the confocal sputter coater has a DC power supply (0-1200 V, 0-500 mA DC power supply), and an RF power supply (220V-240V, 50/60HZ, 16 A) with an automatic matching box.

The Triple Target Sputter Coater DST3-A with three cathodes is suitable for sputtering on substrates with a maximum size of 3. If your substrates are bigger than 3 inches, you could use DST3-S that supports 6 Inches. A fully automatic touch screen control is supplied to register the data as well as record and plot the coating parameters. Users can easily transfer any data via a USB port. This system has dimensions of 50 Cm H x 60 Cm W x 47 Cm D with shipping weight, 120kg (Pump, Rack, and Box).

For more information about the Triple Target Sputter Coater DST3-A and the other Vac Coat’s vacuum coating system, refer to the company’s website.