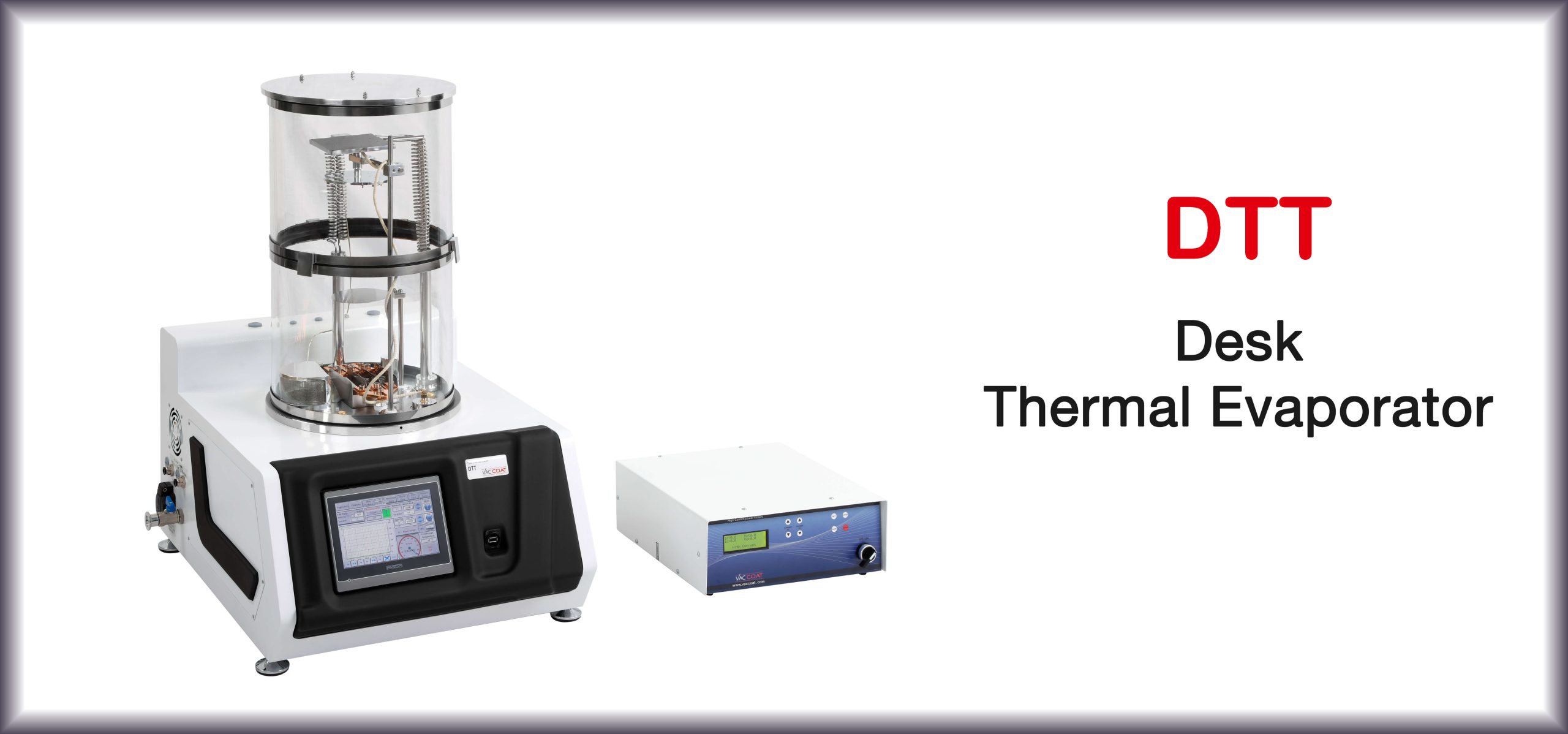

The DTT is a desktop, turbomolecular-pumped thermal evaporator for vacuum deposition of thin films. Different evaporation sources (boat/basket/coil) can be installed on the triple-source evaporation system on the baseplate. Adjustable substrate holder position through the touch screen is ideal for the deposition of single/multilayers or alloys.

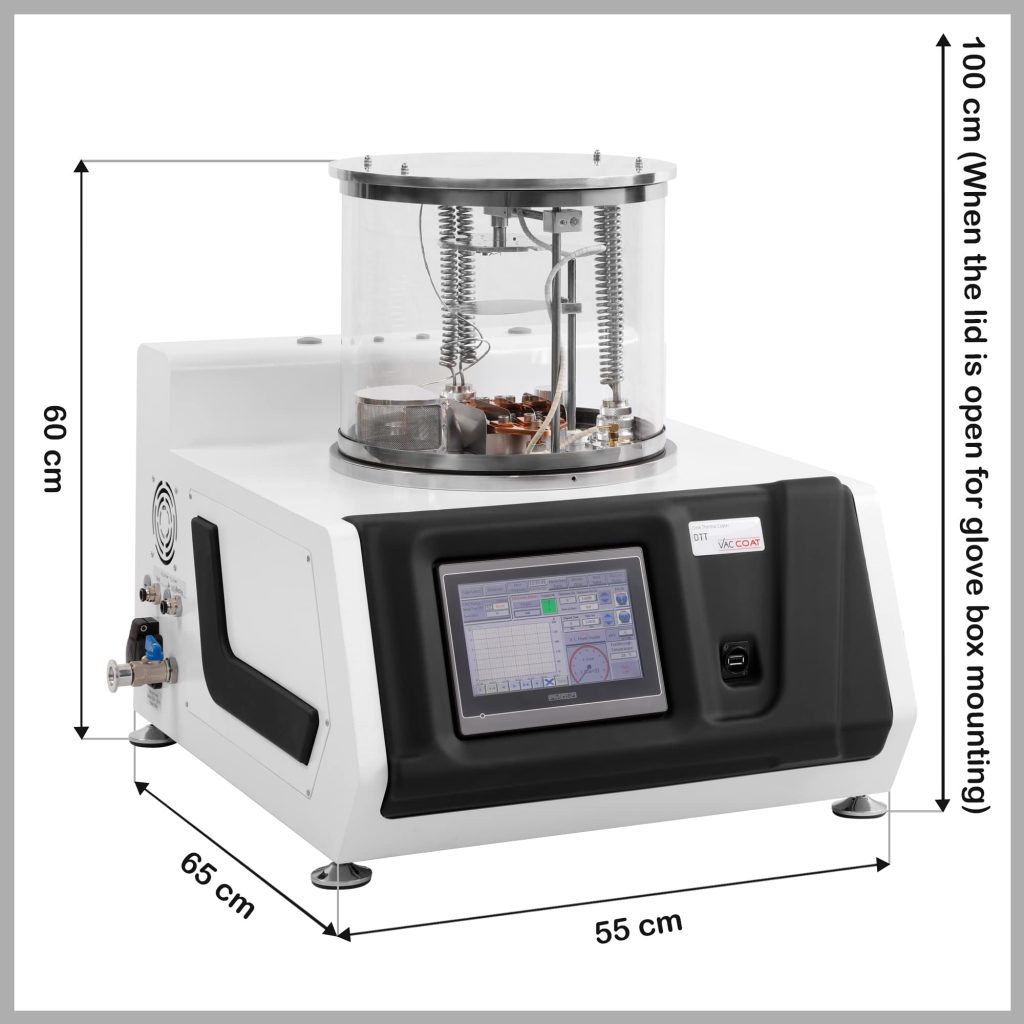

This vacuum evaporator with its suitable dimensions is capable of reaching the desired pressure in a short time and the coating process can take place within a few minutes. This coating system is ideal for laboratory research applications. Furthermore, it can be installed inside a glove box for the deposition of air-sensitive materials.

Features

Hardware

- High-current DC power supply (12V, 100A), short-circuit protected

- High-vacuum built-in turbomolecular pump

- Two-stage rotary vane backing pump (6m3/h), scroll or diaphragm pump as the backing pump (optional)

- Full range vacuum gauge

- Quartz crystal monitoring system for real time thickness measurement (1 nm precision)

- Electronic leak valve

- Electronic shutter

- Sample rotation, height, and tilt adjustable

- 2-inch, 500 ± 1 °C substrate heater (Optional)

- Substrate cooling system (Optional)

- Glove box installation interface (Optional)

- Water flow and temperature sensors

- Two-year warranty

- Vac coat Products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

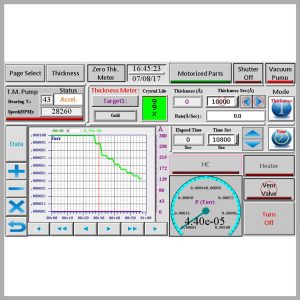

Automation

- Intuitive touch screen to control the vacuuming process and device manipulation

- User-friendly software updatable via network

- Manual or automatic Timed or Thickness deposition (Optional)

- Evaporation source (boat/basket/coil) selection for multilayer thin film deposition

- Records and plots coating parameters graphs

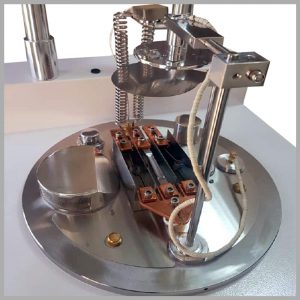

Thermal Evaporation Sources (Boat/basket/coil)

The DTT, desk thermal evaporator, can be fitted with three independent heat resistance thermal evaporation sources. The good design of the evaporation source holder causes no contamination from source materials on each other. The length of the source holders can be adjusted in the range of 5-9cm.

Clean Vacuum of Desk Thermal Evaporator

The vacuum chamber is a Cylindrical Pyrex with 300 mm OD and 250 mm H, and the height can be multiplied by an optional extra cylindrical Pyrex of the same size. The DTT is fitted with an internally mounted 90 L/s turbomolecular pump, backed by a 6m3/h two-stage rotary vane pump (Optional). It introduces a clean vacuum without oil contamination which normally exists with an ordinary diffusion pump.

Touch screen control

Desk thermal evaporator is equipped with a 7” colored touch-screen panel using user-friendly software to control the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touchscreen and the last 300 coatings are saved on the history page.

Specifications

- Deposition of multi-layer thermal coatings

- Co–evaporation to form alloy films (Optional additional power source)

- Turbo molecular pump with different pumping speeds (Optional):

| Pumping Speed | 90 l/s | 250 l/s | 350 l/s |

| Ultimate Pressure | 8 x10-6 Torr | 3 x10-6 Torr | 8 x10-7 Torr |

- Multi boats, baskets, and coils installation

- Real-time plot of coating parameters

- Deposition process curves and data transfer by USB port to PC

- 0-12 V, 0-100 A high-current DC power supply, short-circuit protected

- Utilities: 220/110V, 50/60HZ, 1.2 kW

- Dimensions: 60 cm H × 65 cm W × 50 cm D

- Shipping weight: ~ 30 kg (Excluded backing pump)

Options and Accessories

The DTT has the following options and accessories:

- High current power supply for co-evaporation

- Quartz crystal thickness sensors

- Spare glass chamber

- Evaporation sources (Boat/basket/coil)

- 2 inches, 500 ± 1 °C substrate heater

- Rotatory sample holder

- Sealing gaskets

- Substrate cooling holder

Applications of DTT

- Different kinds of thin film sensors

- Optical components

- Nano & Microelectronic device fabrication

- Solar cells

- Lithium battery fabrication

- Metal thin films