DTE is a desktop thermal evaporator system to deposit thin layers of materials on the substrate for research purposes and investigation by electron microscopy. DTE is configured as a material evaporator suitable for sample evaporant experiments. This low-budget, small chamber, and high-vacuum system is ideal for short time deposition of noble and oxidizing metals.

Thermal Evaporation

DTE is equipped with a high current power supply and low-voltage (Resistive) thermal evaporation platform suitable for a wide variety of thermal evaporation applications. The system allows controlled thermal evaporation of a wide range of materials onto the substrate. Different types of thermal evaporation sources (Boat, basket, and coil) can be installed on the single thermal source holder.

Features of DTE

Hardware

- DC high-current power supply (Max. 12 V, 100 A)

- 170 mm diameter Borosilicate-SST vacuum chamber

- High vacuum level with built-in turbo pump (Leybold 90 l/s)

- Two-stage rotary (Optional diaphragm or scroll) backing pump

- Quartz crystal monitoring system for real time thickness measurement (1 nm precision)

- Electronic shutter

- Two high-current electric feed-throughs for thermal source insertion

- Movable thermal source holder with possible upward or downward deposition configurations

- Automatic venting valve

- Full range vacuum gauge

- S-Clip sample holder on the chamber lead

- 2-inch rotating sample holder on the base plate (Optional)

- Sample rotation, height, and tilt adjustable (For optional 2-inch sample holder)

- Two-year warranty

- CE conformity

- Vac Coat products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

Automation

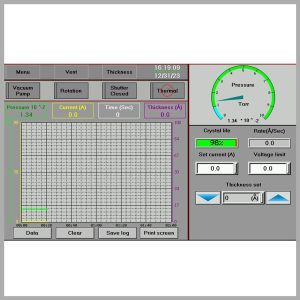

- Intuitive touch screen to control the vacuuming process and device manipulation

- User friendly software, updatable via network

- Semi-automatic evaporation process control

- Controlled thin film deposition based on the set thickness

- Records and plots coating parameters graphs

Clean Vacuum

DTE is fitted with an internally mounted 90 L/s turbo molecular pump, backed by a 6 m3/h two-stage rotary vane pump (Optional).

Touch Screen Control

DTE is equipped with a 7” colored touch-screen panel using user-friendly software to control the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen and the last 300 coatings are saved on the history page.

Sample Holder Stages

DTE deposition system enables metal evaporation in upward and downward configurations.

- Upward deposition: The material is loaded in a boat source and the sample is attached to the S-Clips on the chamber lead to allow easy access.

- Downward deposition: A small amount of desired material is loaded in the basket with rotating sample holder (Optional) on the baseplate.

DTE Operation Requirements

DTE is a deposition system with a small chamber, making it a compact, light-weight, quick- vacuuming, and low-budget coating device. Although, due to its small chamber, there are some advisory notes regarding this device:

- DTE is ideal for short-term thin film coatings, whereas long-term thick layer depositions may damage the chamber.

- The device is ideal for deposition of source materials with low vaporization temperature.

- The maximum sample diameter could not exceed 2 inches for rotating substrate holder.

Options and Accessories

- Quartz crystal sensor

- Spare glass chamber

- Sealing gaskets

- Source boats and baskets

Applications of DTE

- Metal thin films

- Nano and microelectronic

- Solar cell applications

- Thin film sensors

- Fine grain structural deposition for SEM and FE-SEM sample preparation

- Carbon fiber evaporation in flash mode for SEM sample preparation

Specifications

- Ultimate vacuum: Less than 8×10-6 Torr

- 170 mm OD x 140 mm H vacuum chamber

- Fast-cycle deposition process

- Real-time plot of coating parameters

- Deposition process data transfer to PC by USB port

- 0-12 V, 0-100 A DC high-current power supply

- Utilities: 220 V-110 V, 50/60 HZ – 1.2 kW

- Dimensions: 500 H x 450 W x 450 D mm (Without Rack)

- Shipping weight: 30 Kg (Excluded backing pump)