Glovebox Integration in PVD Systems

Certain processes and materials require precise control of environmental conditions to ensure product quality, safety, and research accuracy. Glovebox integrated systems provide a controlled environment with low levels of oxygen and moisture to prevent contamination and oxidation, especially for the deposition of air-sensitive thin films through advanced deposition techniques like sputtering and thermal evaporation, as in solar cell or battery fabrication.

Glovebox System Parts

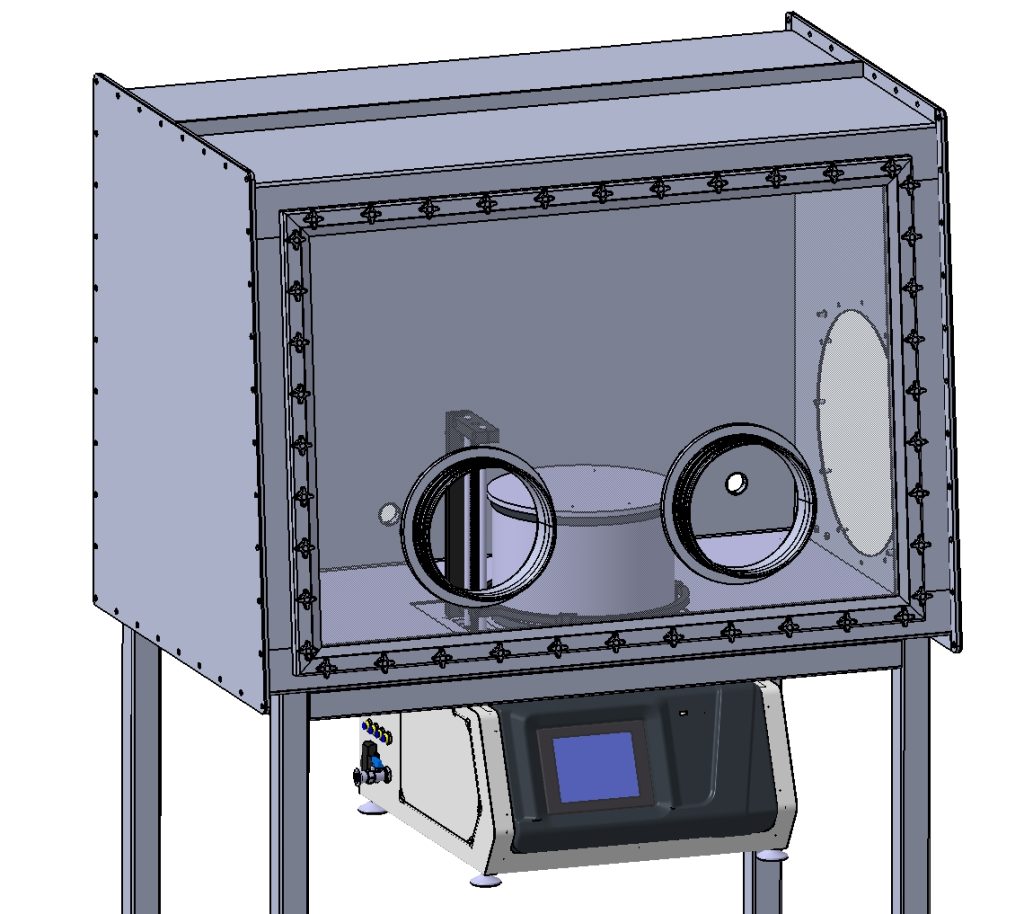

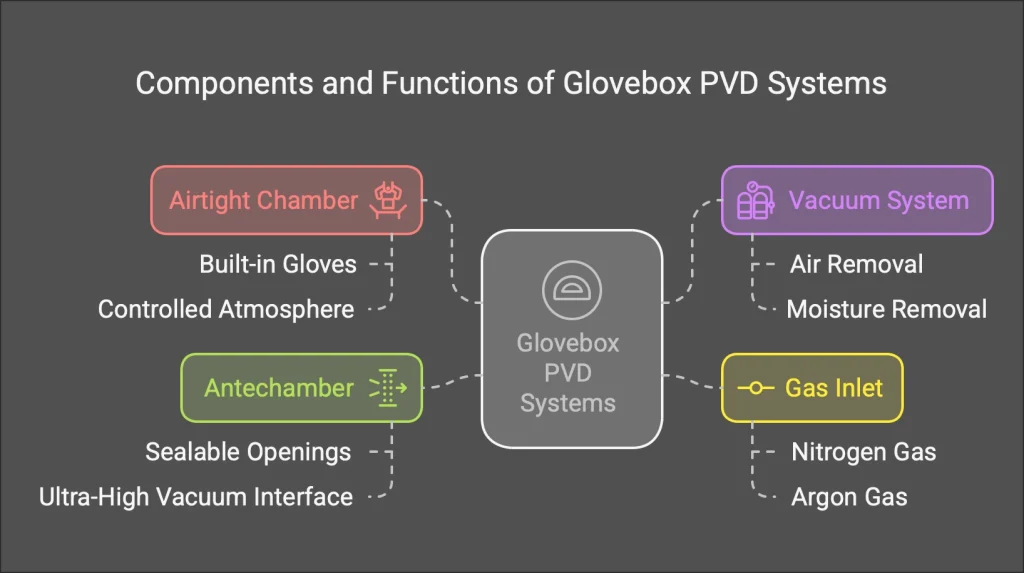

A typical glovebox system mainly consists of the following parts:

- An airtight chamber equipped with built-in gloves to manipulate the materials while maintaining a controlled atmosphere

- A vacuum system that removes air and moisture from the chamber, creating a low-pressure environment

- Gas inlet that allows an inert gas, such as nitrogen or argon to be introduced to replace the removed air, resulting in a controlled atmosphere suitable for sensitive operations

- An antechamber with sealable openings is an entry port to transport materials and items in/out of the main chamber. Also, an antechamber provides an interface with ultra-high vacuum deposition systems such as molecular-beam epitaxy and analysis instruments like scanning tunneling microscopy

Advantages of Using A Glovebox Integrated System

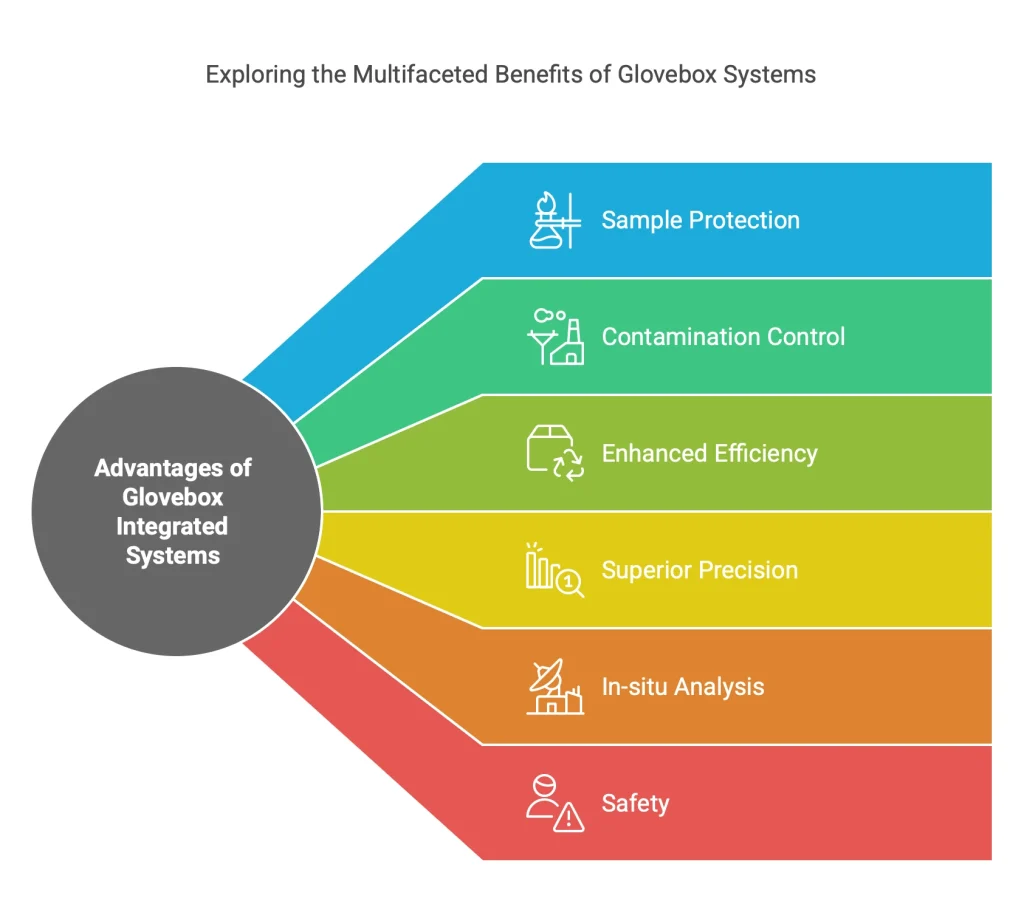

- Sample Protection: Vacuum gloveboxes isolate the materials from air and humidity to prevent undesirable reactions like oxidation, which is essential to maintain the material’s stability and performance

- Contamination Control: The fully controlled environment inside the glovebox eliminates the dust, pollutants, and other contaminations that reach the samples

- Enhanced Efficiency: The unwanted byproducts and wastes are diminished by reducing undesirable reactions and maintaining the material’s quality

- Superior Precision: The controlled atmosphere within the glovebox improves the accuracy of the research and analysis results

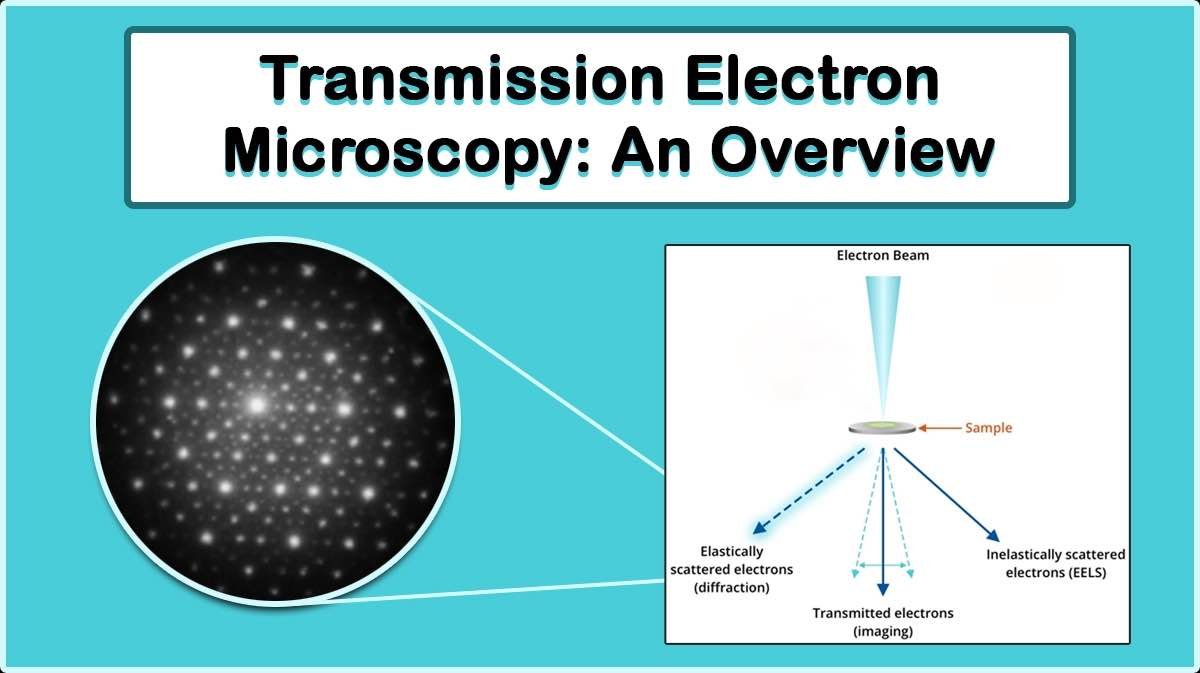

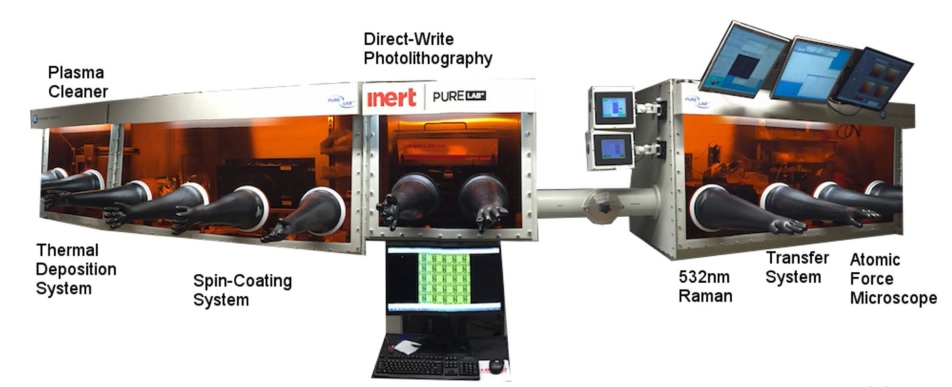

- In-situ Analysis: Characterization systems like electron microscopes (SEM or TEM) can be installed in another glovebox connected by an antechamber to provide precise analysis after the manufacturing process. Also, the sample preparation steps typically required before some analysis, like deposition of a thin conductive layer on the sample before electron microscopy imaging by sputtering or thermal evaporation deposition, can be performed within the glovebox deposition systems

- Safety: Protects users from toxic and volatile materials using sealed glovebox ports

Glovebox Coating Systems

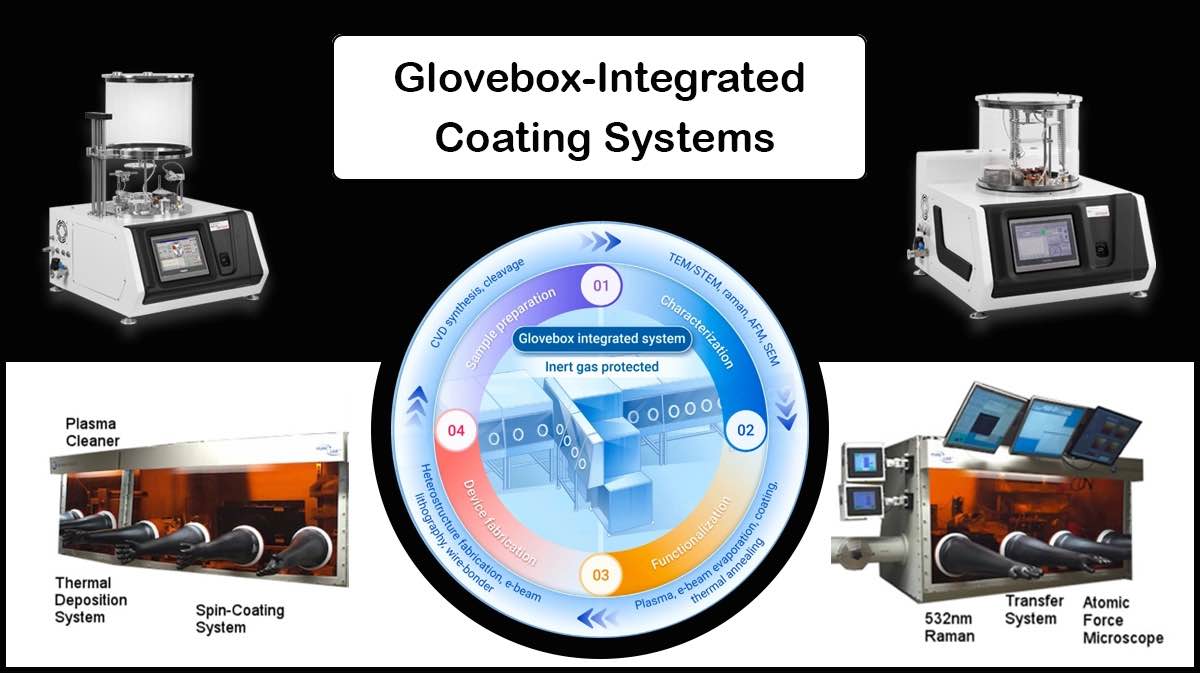

Operating deposition techniques within the controlled environment of a glovebox enhance the resulting material properties and help to achieve specific features. After thin film deposition in a glovebox vacuum coating system, the samples can be stored, prepared, and tested in a high-purity inert gas atmosphere in the glovebox.

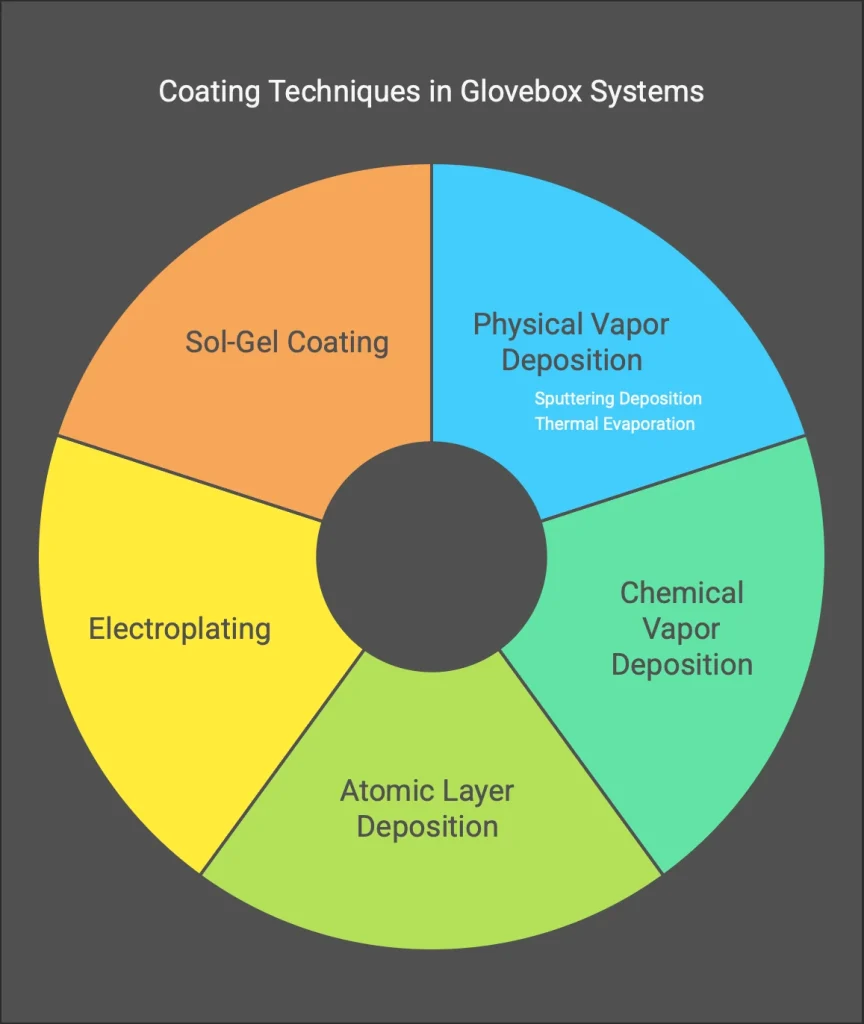

Glovebox integrated systems can be utilized in various applications, from basic research to complex manufacturing processes. The most prominent coating methods in glovebox compatible systems are as follows:

- Physical Vapor Deposition (PVD)

- Sputtering Deposition

- Thermal Evaporation

- Chemical Vapor Deposition (CVD)

- Atomic Layer Deposition (ALD)

- Molecular Beam Epitaxy (MBE)

- Electroplating

- Sol-Gel Coating

Vac Coat manufactures tailored glovebox PVD systems for precise thin film deposition for research purposes. Desktop thermal evaporator, model DTT, and sputter coater and thermal evaporator for glovebox mounting, model DST2-TG, are two Vac Coat glovebox compatible systems.

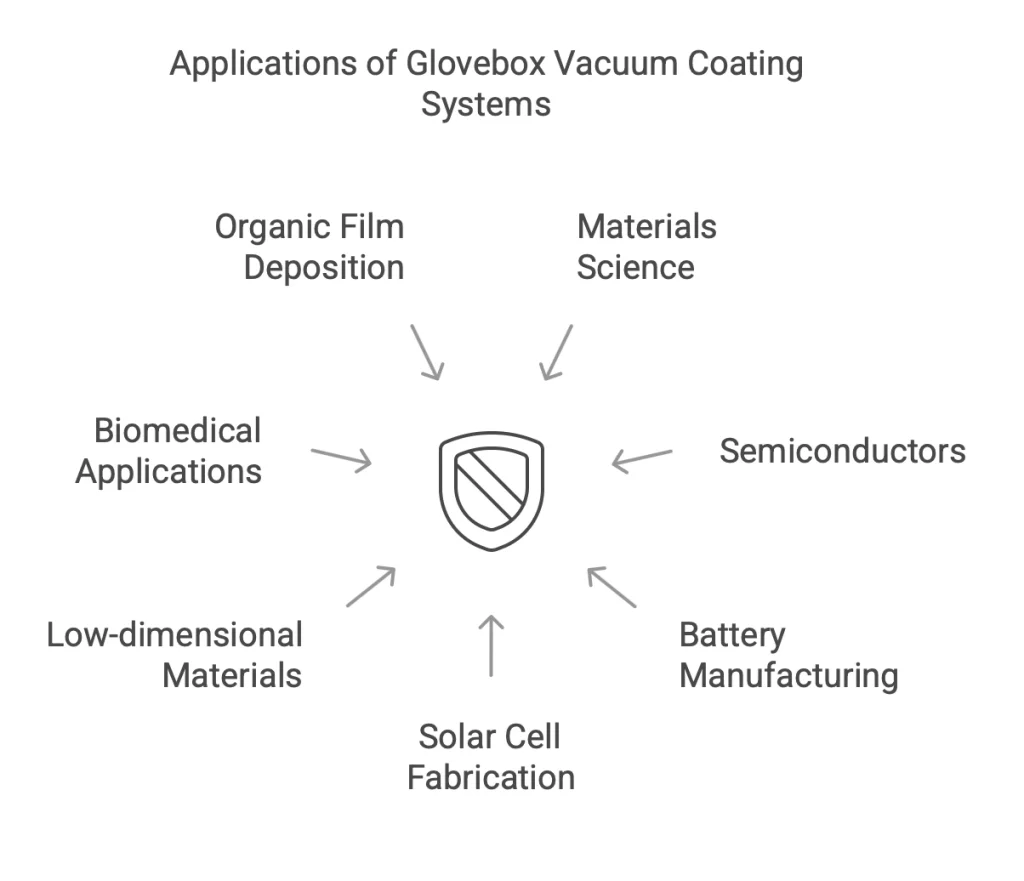

Glovebox Vacuum Coating Systems Applications

Glovebox integrated systems are useful in a variety of applications. The glovebox integration of the deposition systems allows precise control over the chamber environment, which results in a clean thin film coating without unwanted reactions and contaminations, enhancing the functionality and durability of coated products. This critical feature is beneficial in many applications, including:

- Materials Science: Vacuum glove boxes are used in laboratories to manipulate materials sensitive to air or moisture and minimize unnecessary reactions that enable the creation of coatings with unique features

- Semiconductors and Electronics: Vacuum gloveboxes can be used in the electronics industry to prevent oxidation and contaminations in the fabrication process of precise electrical components, like thin film transistors, MEMS devices, organic large-area circuit preparation, and organic optoelectronic devices and circuits

- Battery Manufacturing: The fabrication process of thin film and Li-ion batteries is improved by using vacuum glove boxes to reduce moisture and oxygen in the atmosphere and enhance battery performance

- Solar Cell Fabrication: Solar cell synthesis, especially perovskite solar cells, can be fully controlled and encapsulated within a glovebox environment since the manufacturing process contains materials that are both toxic and sensitive to ambient air (Oxygen/moisture), which can be corrosive in combination with humidity

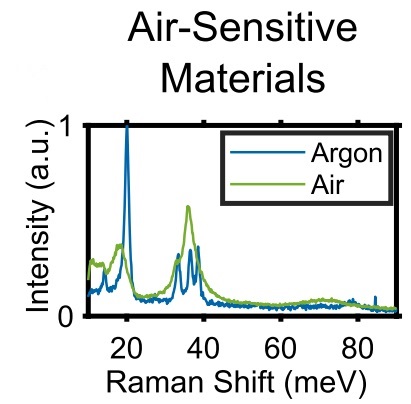

- Low-dimensional Materials: The synthesis of nanostructures like nanoparticles, nanowires, and quantum materials can be improved using a vacuum glovebox. These air-sensitive structures are highly vulnerable to contaminations during the synthesis, manipulation, or characterization processes because of their low layer numbers and the crystal’s sensitivity to strain. For example, the 2D MnBi2Te4 surface degrades when exposed to air through reactions with oxygen and water molecules, resulting in surface oxidation or hydrolysis reactions

- Biomedical Application: Vacuum gloveboxes can enhance the purity of active ingredients of pharmaceutical materials and the handling of sensitive compounds

- Organic Film Deposition and OLED Fabrication

Considerations in Utilizing Glovebox Integrated Systems

Using a glovebox requires extra maintenance protocols, including regular inspection of glovebox functionality and the operator’s ability. Some of the main issues are noted here.

- Gas Connections: The inspection of inert gas connections and safe handling and management of gas cylinders is crucial to preserve the desired controlled atmosphere in the glovebox

- Leak Detection: Vacuum leaks in vacuum systems like glovebox vacuum coating systems can cause severe system deficiencies and threaten operator safety. The main leakage sources in a glovebox can be the gaskets, seals, and gloves, which should be inspected regularly to prevent vacuum leakages

- Compatibility of Material: The specific environment chosen within the glovebox should be well-matched with the working materials to be safely handled. In some cases, the materials processed within the glovebox can cause outgassing and directly affect the quality of the atmosphere and the ability of the system to maintain the desired environment

Vac Coat Glovebox Compatible Systems

Vac Coat Ltd. offers a variety of physical vapor deposition systems, including sputter coaters, carbon coaters, thermal evaporators, and pulsed laser deposition systems that fully satisfy state-of-the-art research projects. Vac Coat also manufactures coating systems specially designed for glovebox integration like Desk thermal evaporation systems (DTT) with triple source holders, enabling multiple and co-deposition processes, and combined double-cathode sputter coater and thermal evaporation system (DST2-TG) that can switch between the sputtering and thermal evaporation processes without breaking the vacuum. DST2-TG is specially designed for glovebox mounting in two in-deck and on-deck configurations.

Conclusion

The glovebox-integrated systems, including glovebox PVD systems, can provide a controlled environment for the fabrication of air-sensitive, low-dimensional, and toxic materials for use in research and industry. Glovebox integration of vacuum coating systems and analysis instruments can greatly enhance the production of advanced materials for various applications in electronics, solar cell, and battery fabrication, etc.

Some of Vac Coat Systems

References

- https://www.ossila.com/

- Gray, Mason J., et al. “A cleanroom in a glovebox.” Review of Scientific Instruments 91.7 (2020).

- Yang, Qishuo, et al. “Unified transmission electron microscopy with the glovebox integrated system for investigating air-sensitive two-dimensional quantum materials.” The Innovation 6.1 (2025).