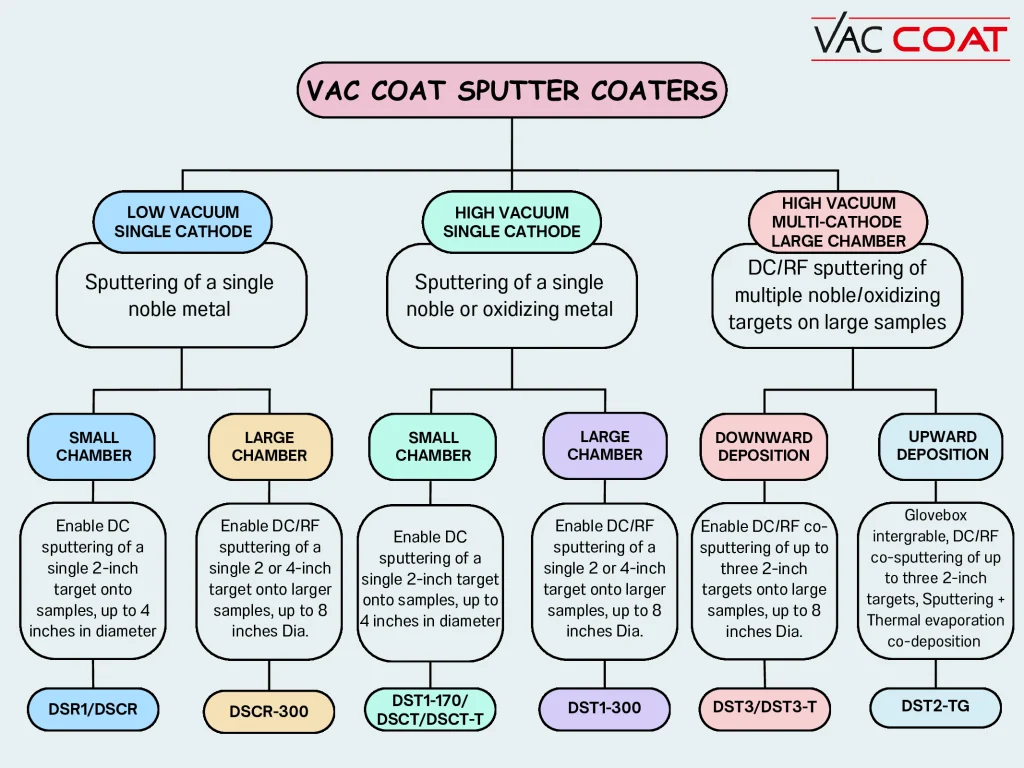

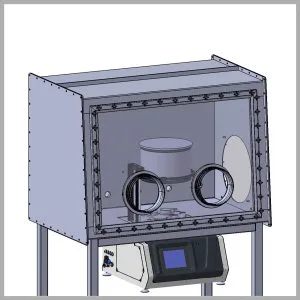

The DST2-TG, double-target turbo pumped sputter coater with thermal evaporator for glove box use, is a multi-vacuum coater system that combines thermal evaporator and sputter coater in one single compact desktop system. The high vacuum system is suitable for the deposition of a wide range of materials. Double magnetron target desk sputter coater can easily switch between evaporation and sputtering deposition for the preparation of multilayer coatings, without breaking the vacuum.

Glove box systems provide a protected environment for sensitive material, preventing any contact with air or humidity and unwanted interactions. DST2-TG high-vacuum coating system with glove box offers a convenient chamber environment contributing to high purity thin layer deposition under high vacuum conditions, along with secure substrate handling under inert gas atmosphere.

The DST2-TG magnetron desk sputter coater is a high-precision semi/fully automated vacuum coating system equipped with a large chamber (300 mm diameter) and two 2” diameter water-cooled cathodes, which make it suitable for long-time deposition. The system is a single platform for sputtering, carbon fiber, and metal evaporation. The magnetron desk sputter coater can sputter semiconductors, dielectrics, and metal targets. Sputtering cathodes and thermal evaporation boats could be installed together or interchangeably, with an overall three deposition sources accessible (When placing the order). Carbon deposition is also made possible by utilizing carbon fiber (Thread).

This sputter coater and thermal evaporator for glove box can be equipped with optional facilities including:

- RF power supply with an auto-adjustable matching box which minimizes the reflected power in the RF sputtering process

- Glow discharge plasma for removing organic matter from the substrate surface before thin film deposition

Features of DST2-TG

- Two-stage rotary vane backing pump

- High-vacuum built-in turbo pump 90 l/s

- Full range vacuum gauge

- Electrical lift arm to ride up and down the vacuum chamber

- Two 2” water-cooled sputtering cathodes

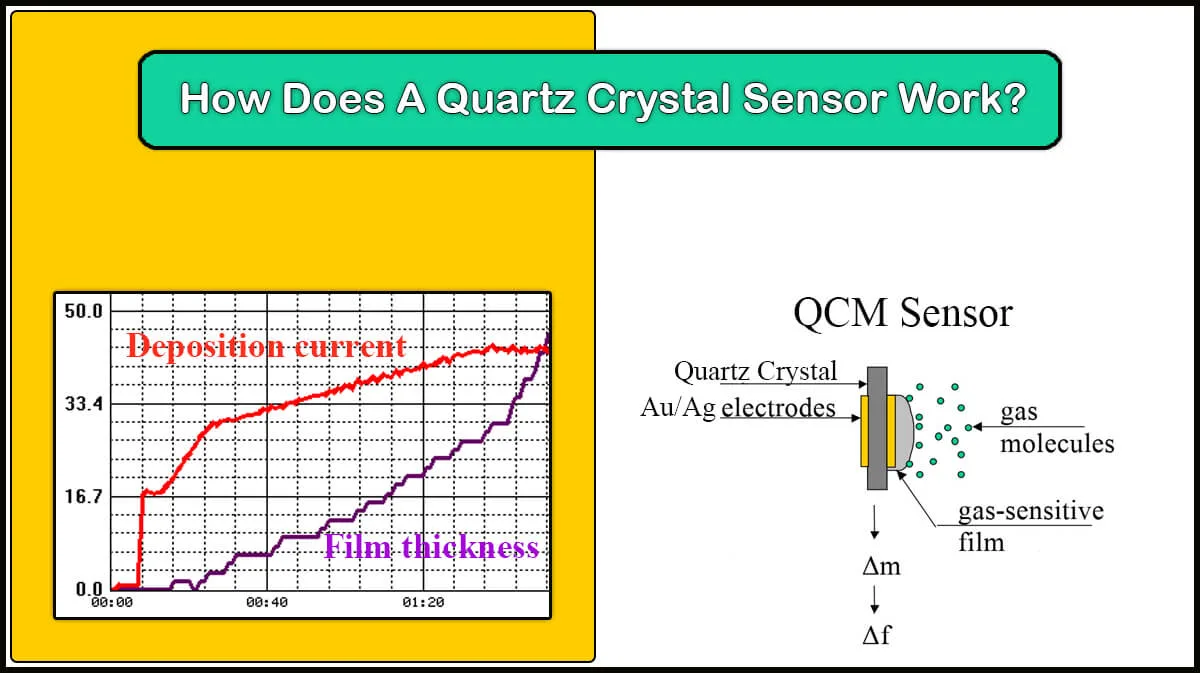

- Two quartz crystal sensors (1 nm precision) for real-time thickness measurement

- Two precision Mass Flow meter (MFC) for fine control of vacuum and pressure

- Electronic shutters

- Cathode selection motor

- Sample rotation, height, and tilt adjustable

- Two-year warranty

- CE conformity

- Vac Coat products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

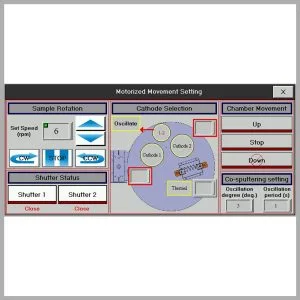

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software, updatable via network

- Semi-Full automatic coating process

- Software controllable vertical movement of the vacuum glass chamber

- Manual or automatic sputter coating in Timed and Thickness modes

- Storing sputter coating recipes for repeatable depositions

- Automated cathode selection for multilayer thin film deposition

- Co-sputtering with sample oscillation settings

- RF sputtering for deposition of non-conducting targets

- Glow discharge plasma

- Metal, semiconductor, and dielectric Films

- Nano and microelectronic

- Solar cell applications

- Thin film battery applications

- Co-Sputtering processes

- Glad sputtering

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

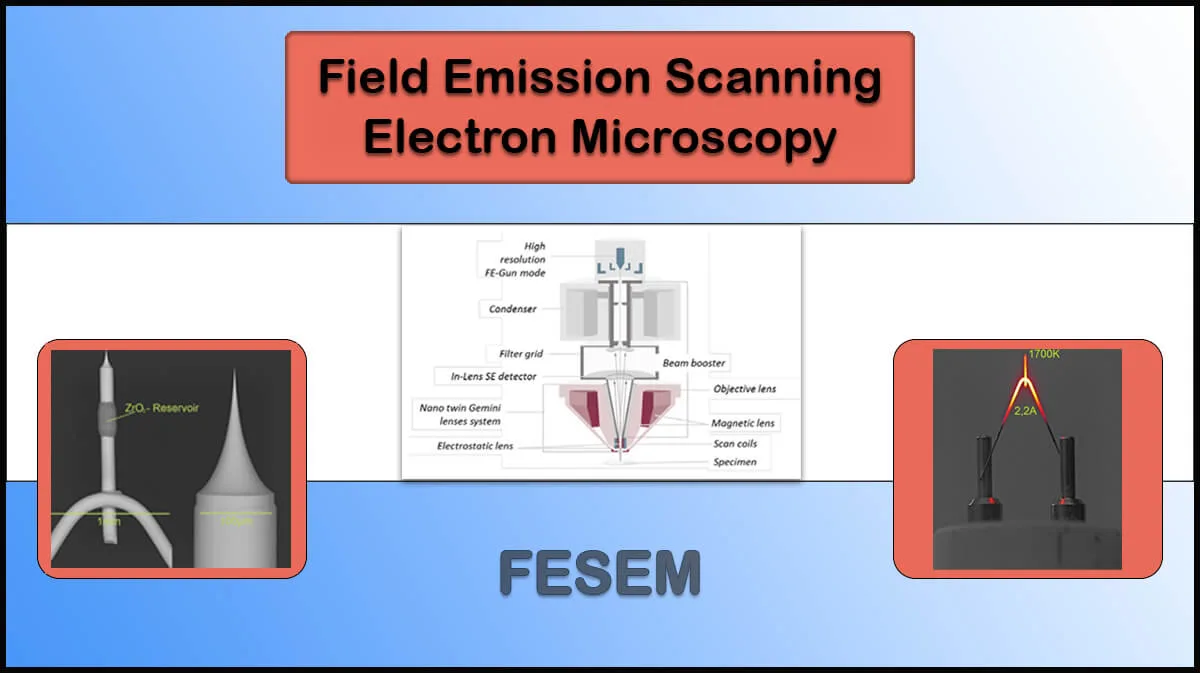

- Fine grain structural deposition for SEM and FE-SEM sample preparation

- Combination of sputter coater and thermal evaporator for glovebox mounting

- Easy and quick target installation without need to target holder

- Improved heat conduction utilizing targets with backing plate

- Unlimited sputtering time without breaking vacuum

- Independent sputtering control rate for each cathode to produce fine grain structures

- Automatic safe control of the cathode’s temperatures to protect the life time of the magnets

- Real-time plots of coating parameters graphs

- Max. power consumption: 4.5kW

- Quartz crystal sensor

- Spare glass chamber

- Sputtering targets

- Sealing gaskets

- Thermal source holders (Boat/ basket)

- Glow discharge plasma rod

Clean Vacuum

The vacuum chamber is Cylindrical Pyrex with 300 mm OD and 200-250 mm H. The DST2-TG is fitted with an internally mounted 90 L/s turbo molecular pump, backed by a 6 m3/h two-stage rotary vain pump. The glove box mounted DST2-TG introduces an extremely controllable chamber environment for high purity thin layer deposition, along with safe and clean sample handling before/after a deposition process under inert gas atmosphere inside the glove box.

Touch Screen Control

DST2-TG is equipped with a 7” colored touch-screen panel with a user-friendly interface to control and adjust the deposition process data. Depending on the ordered model, the panel window can be made available outside the glovebox, or on pc through a Wi-Fi connection to easily control the device. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen and the last 300 coatings are saved on the history page.

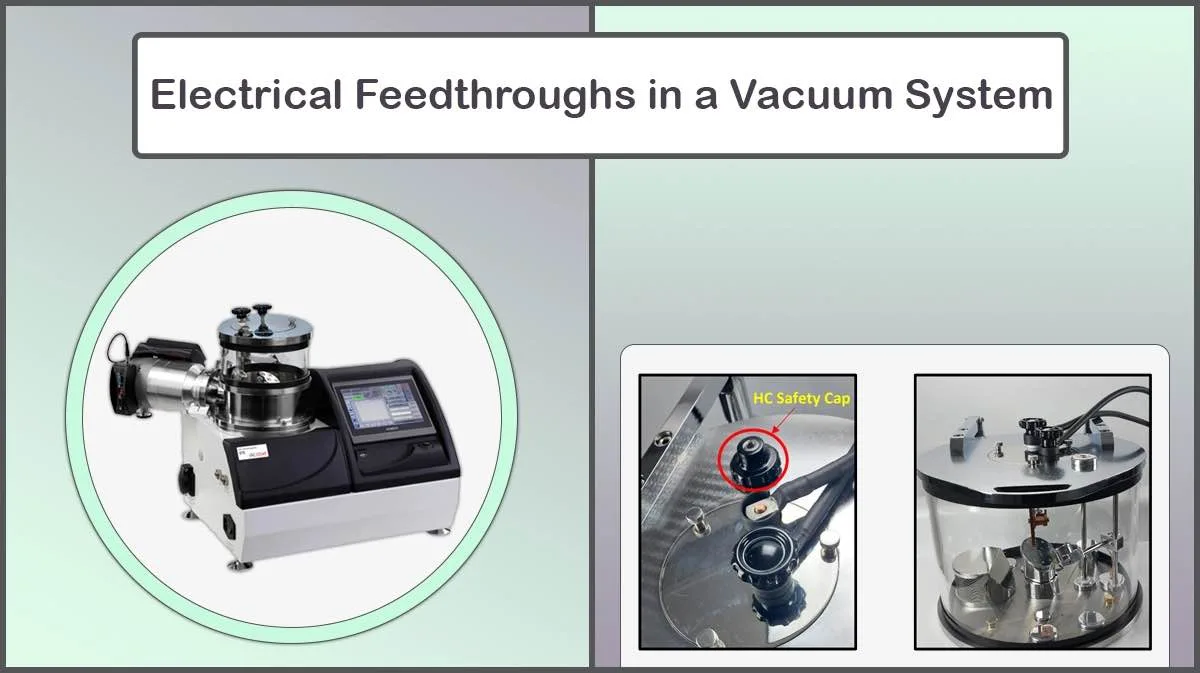

Two Configurations of DST2-TG for Glovebox Integration

DST2-TG-On-Deck

Instrument case (Chamber and connections) is placed completely inside the glove box.

Glovebox mounted KF40 feedthroughs for power supplies, vacuum, water, gas connections, and electrical connections.

The panel window is available on pc through a Wi-Fi connection used for coating process management and data transfer.

DST2-TG-In-Deck

The chamber is placed into the floor of the glove box and sealed by specially designed chamber base.

No Special feedthrough is needed for the electrical, vacuum, water and gas connections.

The panel window is available outside the glovebox to manage coating process. The graphs and data transfer is viable through a USB port.

Detailed Features of DST2-TG

- Dimensions: 705 × 600 × 670 mm (H × W × D) (when the chamber is open, the height is 825 mm)

- Rack Dimensions:

- With RF, DC, High current: 850 × 560 × 710 mm (H × W × D)

- Without RF: 450 × 560 × 710 mm (H × W × D)

- Weight: 80-100 Kg (Instrument case with rack)

- Glass Chamber Dimensions: Pyrex Cylinder Shape, Diameter 300mm, Height 200/250mm (optional), Thickness 7mm

- Glovebox Integration:

- On-Deck model:

- Max. 12xISOKF40 feedthroughs for power supplies (DC, RF, and High- Current (HC)), vacuum pump hose, water cooling, argon/reactive gas and electrical connections should be installed on the glovebox backside (if all accessories ordered)

- In-Deck model:

- A rectangle (470mmx400mm) from the glovebox floor is removed to place and install the chamber base.

- Sealing gaskets on the chamber base, provided by the manufacturer, ensure reaching high vacuum level inside the chamber.

- Before ordering the glovebox, its drawings should be checked with the manufacturer.

- On-Deck model:

- Display Screen: 7” Diagonal (16:9) 800×480 High Color- Graphic TFT- LCD

- User Interface: Color & Touch Screen

- Data Transfer: USB Port / Wi-Fi connection (based on the model)– For Transferring the data and graph to PC

- Target Dimension: 1-3 Discs, 2 inches Dia., Thickness 0.1~6 mm (Less than 3 mm thickness is preferred), Thickness of ferromagnetic targets should be less than 0.5 mm. For long-term, high-power sputtering processes, targets need a ferromagnetic back plate with thickness of 0.1-0.2 mm.

- Thermal evaporation boat/basket Dimension: Length 4-7 cm

- Sample Holder Dimension: Max Diameter 3″

- Chamber’s Lid: Made of Aluminum, chamber and lid up/down movement by electrical lift arm

- Number of Sensors: 2 Pieces

- Specification: Quartz crystal thickness gauge with sensors, oscillator, one is portable

- Resolution: ±1 Angstrom

- Accuracy: ±1 nanometer

- Turbo Molecular Pump: Pumping speed: 90 l/s, (Leybold)

- Backing Pump: Two-stage rotary vane vacuum pump or diaphragm/scroll pump (Optional)

- Pressure Gauge: Leybold (Ionivac model); Full Range

- Ultimate Vacuum Pressure: <8×10-6 Torr

- Sputtering Process Vacuum Range: 5×10-2~ 5×10-3 Torr

- Sputtering: Continuous Sputtering, Time, and Thickness dependent

- Thermal Evaporation: Continuous deposition, Time and Thickness dependent (limited deposition time operating at current more than 50A)

- Glow Discharge Plasma (Optional):

- TEM grid plasma treatment

- Enhancing surface hydrophilicity

- Gas: Argon as a carrier gas with %99.999 purity, and Oxygen or Nitrogen as reactant gases

- Electric Power Supply:

- RF: 300 W, 13.56 MHz (Optional)

- DC: 500 mA, 1200 V

- High Current: 100 A- 12 V

- High current Feedthrough: 2 water-cooled

- Vent Valve: ¼”, one quick gas connector for ventilation (size 6×4 mm)

- Ar and reactive gas connections: Two quick gas connectors (size 6×4 mm)

- Mass Flow Control: 2 pieces, 0-100 sccm

- Water inlet/outlet hoses: size 6×4 mm

- Shutter: 2 pieces

- Substrate Rotation speed: 6 – 12 rpm, with controllable speed and changeable direction

- Cathode Selection: Transferring the substrates against one cathode to the other ones or between them without breaking the vacuum

- Electrical Inlet: Inlet: 110 or 220 V, 50-60Hz *

* Single-phase AC power with appropriate earth connection is required.

Dear Siror Madam,

I am interested to learn more about the Sputter Coater and Thermal Evaporator – DST2-TG combined with the plasma functionality. Could you please also send me a quote?

I am interested in placing the DST2-TG inside a glovebox for cleaning substrates and evaporating metal layers on top of 2D materials, which will be exfoliated inside in a glovebox as well.

Thank you in advance

Dear Alexandros

Sure, Could you send your request here, please: https://vaccoat.com/quote-request/