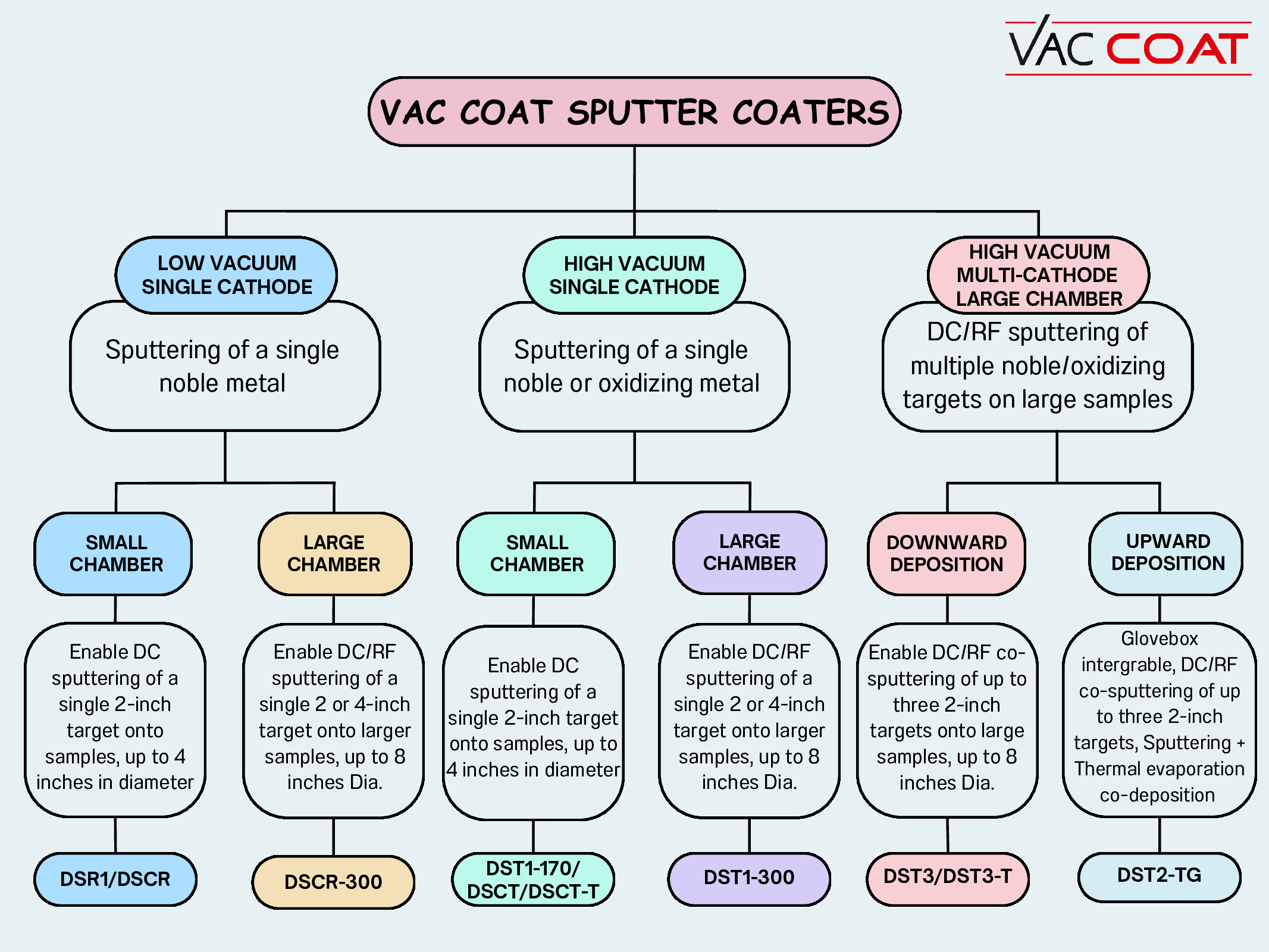

The DSCT-300 is configured as a dual sputter coater and carbon coater capable of performing successive sputtering and carbon evaporation deposition with fine-grain sizes without breaking the vacuum in a large 300 mm dia. chamber, suitable for research purposes and scanning electron microscope (SEM) sample preparation.

This device can be used for the deposition of uniform coatings of semiconductors, dielectrics and metals (Noble and oxidizing) (Deposition Material Table), such as gold (Au), platinum/palladium (Pt/Pd) alloy, silver (Ag), chromium (Cr), tungsten (W), iridium (Ir), etc., together with carbon thread (Fiber)/rod to coat thin films on various surfaces, for different applications like micro and nano-electronic, metalizing and electron microscopy imaging.

The DSCT-300 high vacuum coater is equipped with a turbomolecular pump that offers high-quality uniform films with fine grain sizes under high vacuum conditions, suitable for specimens that require high resolution characterization such as FE-SEM, EDS/WDS, TEM, and EBSD.

The DSCT-300 coating system is equipped with a 160W switching DC and 24V high current power supply. As optional facilities, the sputtering can be executed with a power of up to 600 W, as well as performing RF sputtering for sputter coating of insulating materials (Based on the order).

DSCT is equipped with a water-cooled cathode, which makes it suitable for long time sputtering deposition. The full-automatic sputter and carbon coating processes allow easy, precise, and repeatable performance. The maximum size of the substrates in this model could be 8 inches.

Features of DSCT-300

- High vacuum level with built-in turbo pump 90 L/s (Leybold)

- Two-stage rotary vane backing pump (Diaphragm and scroll pump)

- 160 W sputtering switching DC power supply

- 500 W switching DC power supply for carbon fiber deposition

- Carbon fiber (Thread) evaporation head

- Quartz crystal thickness monitor with precision of 1 nm and resolution of 1 Å

- One 2-inch magnetron cathode

- Automatic venting valve

- Sample rotation, height, and tilt adjustable

- Planetary sample holder (Optional)

- Electronic shutter

- Easy-to-change specimen stages (Rotation stage as standard)

- Two-year warranty

- CE conformity

- Vac Coat products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

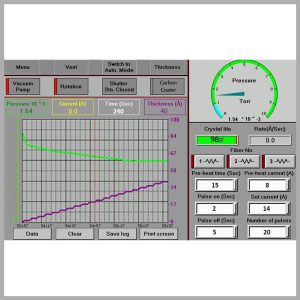

- Intuitive touch screen to control the coating process and rapid data input

- User-friendly software, updatable via network

- Repeatable, programmable coating process in the automatic mode

- Semi-full automatic sputtering deposition process in Timed or Thickness modes

- Semi-full automatic carbon fiber/rod deposition process

- Automatic carbon fiber coating in flash or pulsed modes

- Automatic carbon rod coating in pulsed or ramped modes

- Records and plots coating parameters graphs

- Storing coating recipes for repeatable depositions

- Fine grain structural deposition of carbon and metals (Noble and oxidizing) thin films for SEM, FE-SEM, EDX, and TEM sample preparation

- Nano and microelectronic

- Conductive layers

- Thin Film Sensors

- GLAD sputtering

- TEM grid plasma treatment for improved hydrophilicity (Optional)

- Turbo molecular pump with different pumping speeds (Optional):

| Pumping Speed (Ls-1) | 90 | 250 | 350 |

| Ultimate Pressure (Torr) | 8×10-6 | 3×10-6 | 8×10-7 |

- Precise control over coating rate and pressure to achieve finer grain structures

- Automatic control of the cathode’s temperature to protect the lifetime of the magnets

- Real-time plot of coating parameters

- Max. consuming power: 2 kW

- Appropriate packaging of the instrument for safe delivery

- Head and high-current power supply for carbon rod evaporation

- Quartz crystal sensor (Silver/gold coated)

- Planetary sample rotation stage

- Spare cylindrical vacuum glass chamber

- Sputtering targets

- Cathode mask

- Sealing gaskets

- Carbon fiber source

- Glow discharge plasma

Carbon Evaporation of DSCT-300

The DSCT-300 coating system can coat carbon layers with fine grains to produce uniform thin films on different surfaces using carbon fiber or carbon rods (Optional).

Pulsed Carbon Fiber Evaporation

The DSCT-300 coater is able to perform pulsed carbon fiber evaporation. Short pulses provide more controlled deposition and significantly reduce the amount of debris associated with traditional carbon deposition.

Carbon Rod Evaporation (Optional)

The DSCT-300 could be equipped with a carbon rod evaporator head (Optional). For this case, an external 0-100 A high current power supply should be used instead of the internal high current power supply which is designed for carbon thread evaporation.

Clean Vacuum of DSCT-300

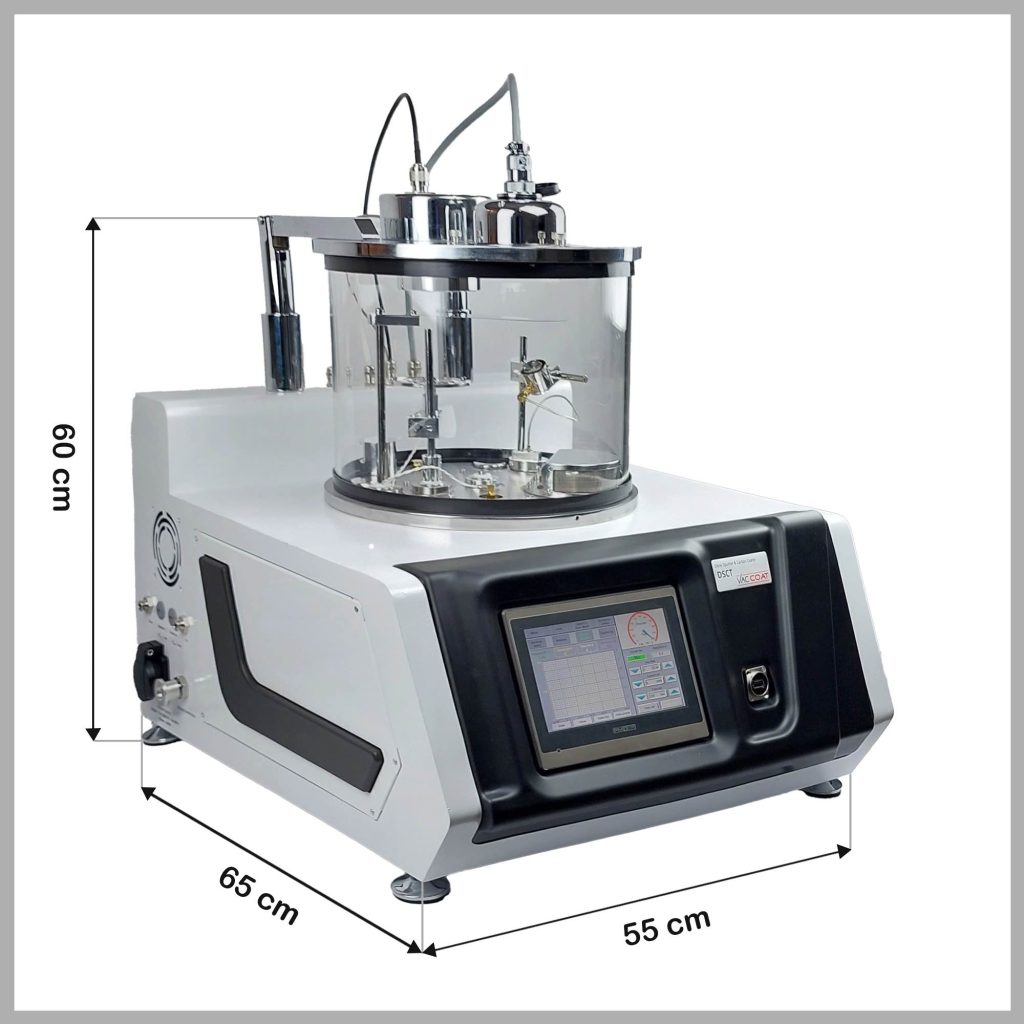

The vacuum chamber is made up of a cylindrical Pyrex with a diameter of 300 cm. The DSCT-300 is fitted with an internally mounted 90 L/s turbo molecular pump, backed by a 6 m3/h two-stage rotary vane pump. It introduces a clean vacuum without oil contamination which normally exists with ordinary diffusion pumps.

Touch Screen Control

DSCT-300 is equipped with a 7” colored touch-screen panel and fully automatic control utilizing user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen. The last 300 coatings information is saved on the history page.

Sample Holder Stages

The DSCT-300 can be equipped with different sample stage configurations depending on the user requirements. The standard sample stage is rotatable with adjustable height and angle and can be changed easily. The rotary planetary sample stage is a good choice for the uniform coating of porous specimens (Optional).

Detailed Features of DSCT-300

- Dimensions: 600 × 550 × 650 mm (H × W × D)

- Weight: 46 Kg (Without backing pump)

- Vacuum Chamber Dimension: Borosilicate Glass, 300 mm Dia.× 50 mm Height

- Display Screen: 7” Diagonal (16:9) 800×480 High Color- Graphic TFT- LCD

- Data Transfer: USB Port – For Transferring the data and graph to PC

- Target Dimension: 1 Disc, Diameter ranging 50-56 mm, Thickness 0.1~3 mm (The preferred Thickness is less than 1 mm), A silver target is installed on the cathode when delivered

- Carbon fiber: Carbon fiber thread diameter: 0.8 mm (Thicker fiber is not recommended)

- Carbon rod: Carbon rod diameter: 3.2 mm

- Sample Holder Dimension:

- 100 mm Dia. rotating sample holder can contain 40×12.7 mm stubs

- Max. 200 mm Dia. rotating stage for more uniform sputter deposition with masked cathode

- Chamber’s Lid: Made of Aluminum/SST that can locate 1 cathode and a head for carbon source holder (Triple carbon fiber (Thread) holder or a rod holder) on it

- Specification: Crystal thickness gauge with sensor, Gold/Silver coated crystal quartz for Sputter/Carbon deposition thickness monitoring (Best result for carbon film thickness monitoring with silver coated QCM), oscillator

- Resolution: ±1 Angstrom

- Accuracy: ±1 nanometer

- Turbo Molecular Pump: Pumping Speed of 90 L/s, (Leybold)

- Backing Pump: Two-stage rotary vane/diaphragm pump/scroll pump

- Pressure Gauge: Leybold (Ionivac model); Full Range

- Final Vacuum: <8×10-6 Torr

- Sputtering Vacuum Range: 5×10-2 ~ 5×10-3

- Sputtering: Continuous Sputtering, Time, and Thickness dependent

- Carbon Coating:

- Pulsed and Flash mode carbon fiber coating

- Pulsed or Ramped mode carbon rod coating

- Glow Discharge Plasma (Optional):

- TEM grid plasma treatment

- Enhancing surface hydrophilicity

- Gas: Argon as a carrier gas with %99.999 purity for sputter coating process

- Electric Power Supply:

- DC: 160 W switching DC power supply

- HC: 24 V, 20 A (Carbon fiber evaporation)

- HC: 12 V, 100 A (Carbon rod evaporation)

- Control of Argon supply: Electronic leak valve

- Shutter: 1 piece

- Electrical Inlet: Inlet: 220-240 V, 50/60 Hz; or 110 V, 50/60 Hz *

* Single-phase AC power with appropriate earth connection is required.

How Does Desk Sputter Coater work?