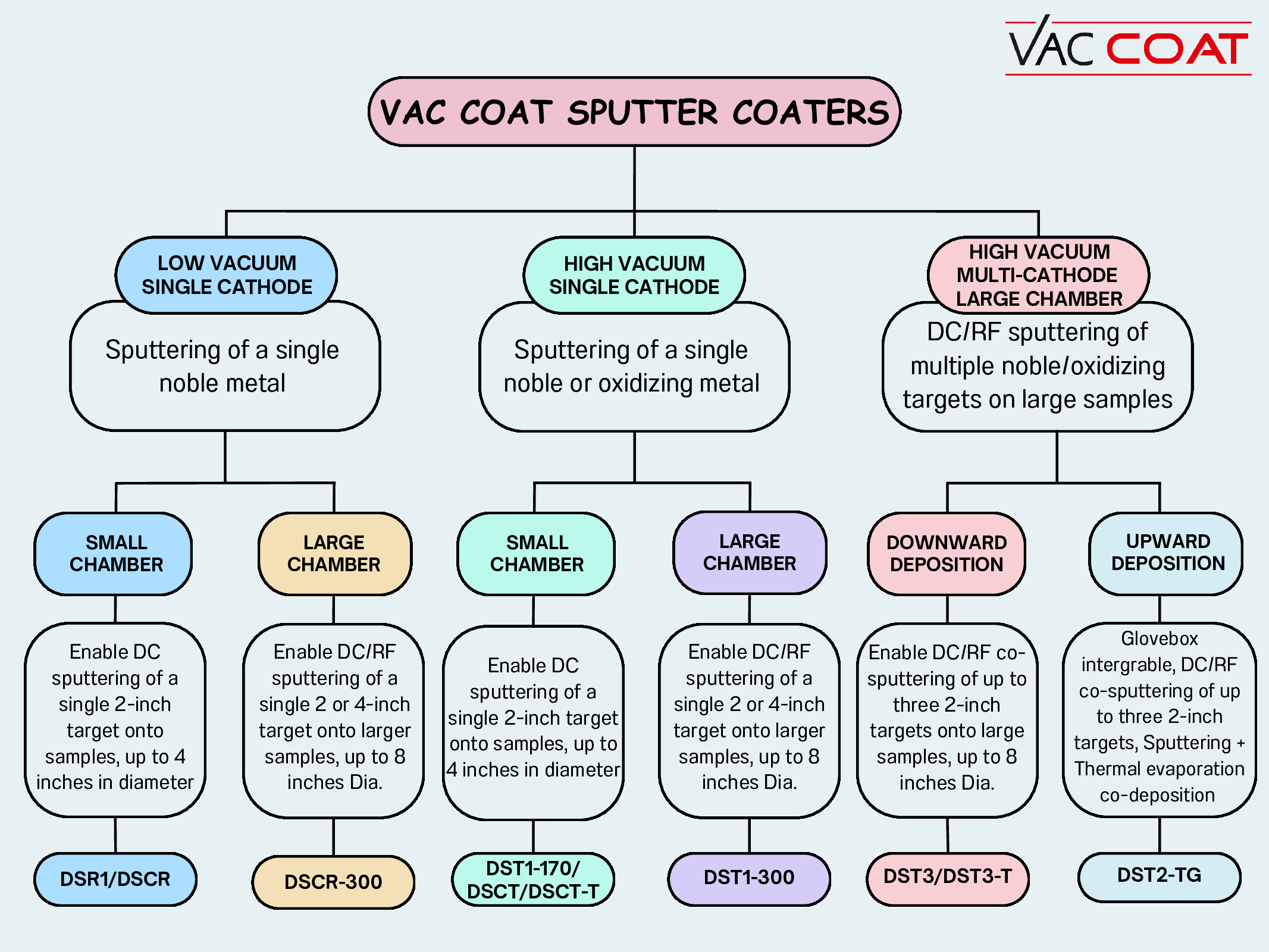

The high-vacuum magnetron desk sputter coater model DST1-170 is a compact coating system with the ability to coat metals (Oxidizing and non-oxidizing), suitable for short-term deposition periods. DST1-170 is able to deposit uniform thin films with fine-grain sizes in a fast cycle time.

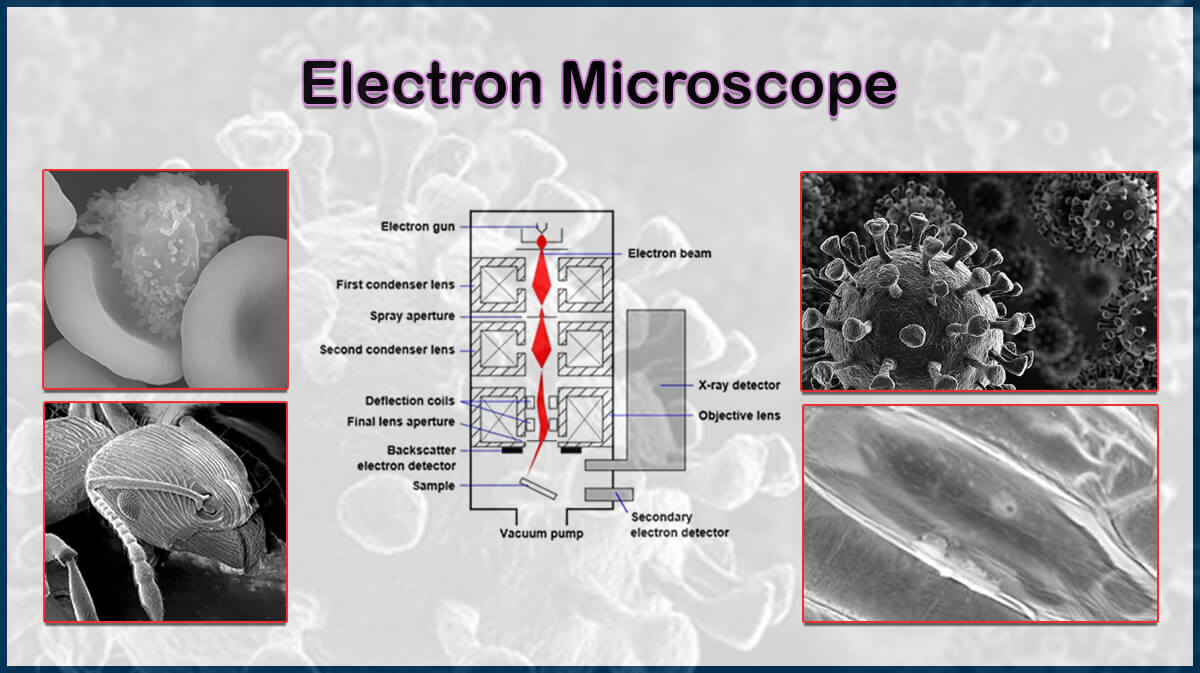

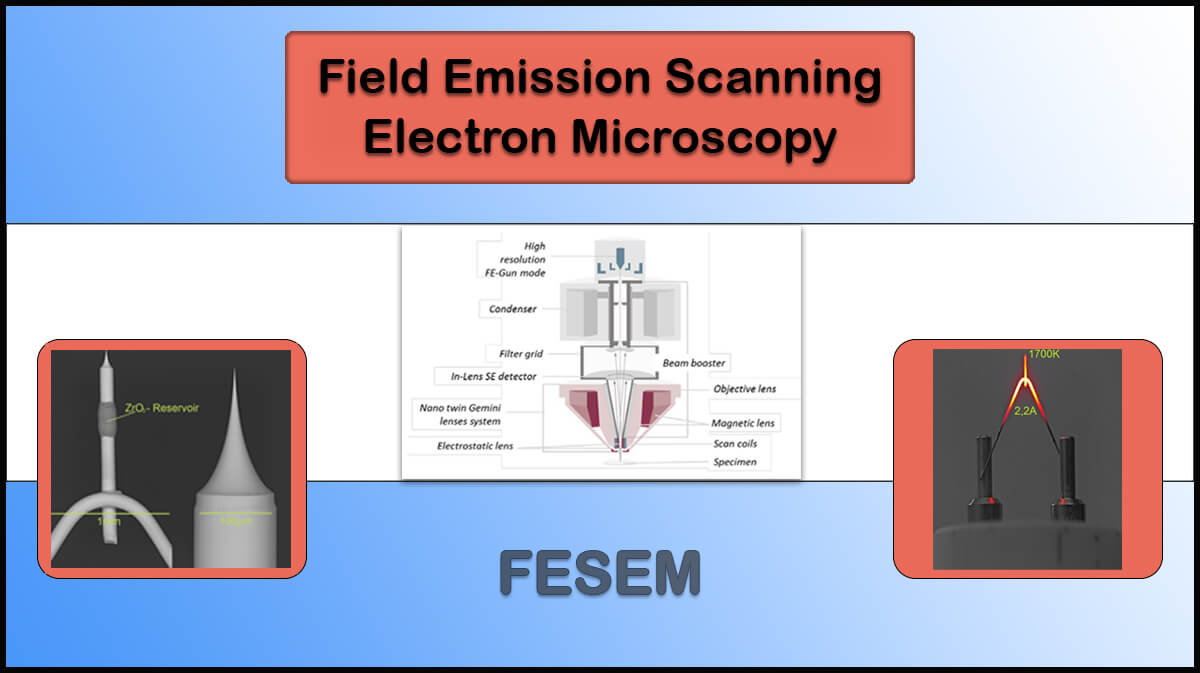

High vacuum sputter coater – DST1-170 is configured as a desk sputter coater suitable for scanning electron microscope (SEM) sample preparation. A wide range of oxidizing and non-oxidizing materials could be deposited by DST1-170 such as gold (Au), platinum/palladium (Pt/Pd) alloy, silver (Ag), chromium (Cr), tungsten (W), iridium (Ir), and etc.

This high vacuum coater, DST1-170, offers high quality uniform films with fine grain sizes which are suitable for specimens that require high resolution and high quality characterization such as FE-SEM, EDS/WDS, TEM, and EBSD. The DST1-170 with a 2” magnetron cathode, 80 W switching DC power supply, could be used for research and different thin film applications.

DST1 can be equipped with a water-cooled cathode which make it suitable for long time deposition.

The maximum size of substrates in this model could be 4 inches.

Features of High Vacuum Sputter Coater

Hardware

- High vacuum level with built-in turbomolecular pump 90 L/S (Leybold)

- Two stage rotary vane backing pump (Diaphragm and scroll pump)

- Full range vacuum gauge

- DC power supply 80 W

- Quartz crystal thickness monitor with precision of 1 nm and resolution of 1 Å

- One 2-inch magnetron cathode

- Electronic leak valve for Argon gas

- Sample rotation, height, and tilt adjustable

- Planetary rotating sample holder

- Equipped with electronic shutter

- Easy-to-change specimen stages (Rotation stage as standard)

- Two-year warranty

- CE standard conformity

- Vac Coat products are covered worldwide by both public and product Liability Insurance in case any property damage or personal injury happens caused by the Vac Coat systems.

Automation

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software, updatable via network

- Controls coating rate to achieve finer grain structures

- Semi-Full automatic coating process (Optional)

- Repeatable and programmable sputtering process in the automatic mode

- Manual or automatic timed and thickness deposition

- Able to record and plot coating parameters graphs

- Storing coating recipes for repeatable depositions

Clean Vacuum of DST1-170

The vacuum chamber is Cylindrical Pyrex. The DST1-170 is fitted with an internally mounted 90 L/s turbomolecular pump, backed by a 6 m3/h two stage rotary vane pump. It introduces clean vacuum without oil contamination which normally exists with ordinary diffusion pump.

Touch Screen Control

The DST1-170 is equipped with a 7” colored touch screen and full automatic control using a user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen. The last 300 coatings information is saved on the history page.

Sample Holder Stages

The DST1 can be equipped with different sample stage configurations depending on the user requirements. The standard sample stage is rotatable with adjustable height and angle and can be changed easily. The rotary planetary sample stage is a good choice for uniform coating of porous specimens (Optional).

Specification of Magnetron Sputter Coater

- Ultimate vacuum: Less than 8 x10-6 Torr

- Suitable for deposition of oxidizing and non-oxidizing materials

- Precise control over the sputtering rate to achieve finer grain structure

- Automatic control of the deposition power independent of pressure

- Automatic control of the cathode’s temperature to protect the lifetime of the magnets

- 170 mm OD × 140 mm H vacuum chamber

- Dimensions: 540 × 500 × 450 mm (H × W × D)

- Rapid data input through colorful touch screen panel

- Real-time plots of coating parameters

- Deposition process data transfer to PC by a USB port

- Utilities: 220 V-110 V, 50/60 HZ – 1.5 kW

- Shipping weight: 36 kg

Applications of DST1-170

- Fine grain structural deposition for SEM and FE-SEM sample preparation

- Nano and microelectronic

- Solar cell applications

- Optical components coating

- Thin film sensors

- Able to perform GLAD sputtering

Options and Accessories

- Quartz crystal sensor

- Planetary sample rotation stage

- Spare glass chamber

- Sputtering targets

- Plasma cleaner

- Sealing gaskets