An Overview of DST2-TG: Sputter Coater & Thermal Evaporator for Glove Box

VacCoat Ltd. has successfully designed and manufactured a new product, desk sputter coater and thermal evaporator for glove box, DST2-TG. This turbo-pump equipped coating system can perform thin film depositions by high-vacuum switchable sputtering and thermal evaporation techniques, enabling multilayer deposition, without breaking the vacuum condition.

Multilayer Coatings by Switchable Sputtering and Thermal Evaporation

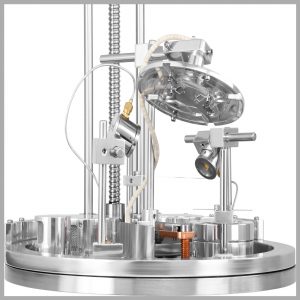

DST2-TG contains two sputtering cathodes and a pair of high-current electrodes for loading one thermal evaporation source, where the number of cathodes/evaporation sources could be modified due to costumer demands, with an overall three deposition sources accessible. Carbon deposition is also made possible by loading carbon fiber on the high-current electrodes.

Coating under Highly Controllable Vacuum Condition

VacCoat Ltd. has introduced DST2-TG to meet the demands of its valuable customers for preparing high-purity coatings and better control over vacuum conditions, made possible by glove box mounted systems like sputter coater/thermal evaporator for glove box –DST2-TG. With the use of deposition systems inside a glove box, the vacuum level could be highly controlled, suitable for deposition of oxidizing coatings.

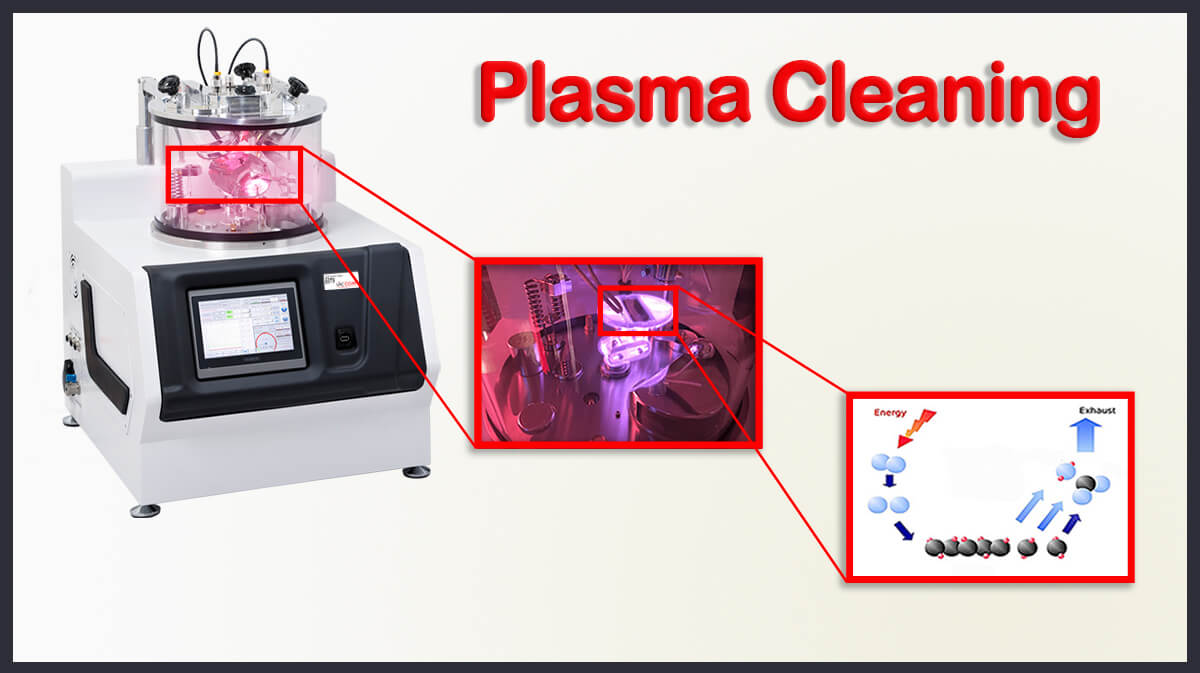

Oxidizing, non-oxidizing and noble metals can be deposited by this coating device. According to the customer, the coating system can be offered with a radio-frequency (RF) power supply to do RF sputtering for insulating/semi-conductor targets deposition. Plasma cleaner is another optional facility provided for this model.

A Quick View on DST2-TG Specifications

Sputter coater and thermal evaporator for glove box, DST2-TG, with a 7” colored touch-screen panel using user-friendly software to control and adjust the deposition process data, can be connected to pc through a Wi-Fi connection; granting access to the panel window on pc while the system is mounted in a glove box.

Important Features of DST2-TG

Another key features of DST2-TG coating system include:

- Glovebox mounted KF40 feedthroughs

- Two-stage rotary vane backing pump

- Full range vacuum gauge

- Large chamber (300 mm diameter, 20-25 cm height) suitable for large specimen depositions

- Electrical lift arm to ride up and down the vacuum chamber

- Two 2” water–cooled sputtering cathodes

- Easy and quick target installation: No target holder needed

- Boosted heat conduction utilizing targets with backing plate

- Two quartz crystal sensors (1 nm precision) for real-time thickness measurement

- Gas injection control through MFCs

- Electronic shutters

- Cathode selection motor

- Sample rotation, height and tilt adjustable

- Manual or automatic timed and thickness deposition

- Storing coating up to 8 recipes for repeatable depositions

DST2-TG Applications

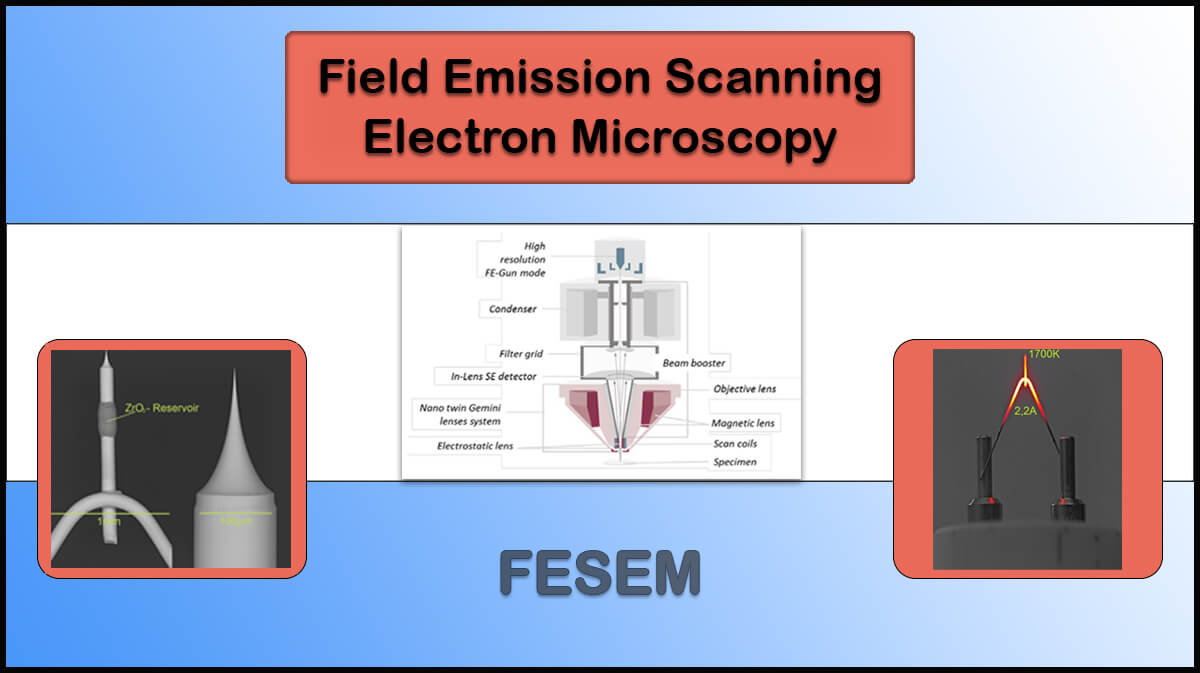

This coating system is optimized for thin film deposition utilized in micro-nano electronics, sensors, solar cells, Li-ion batteries, and many other applications. Also, DST2-TG sputter coater/thermal evaporator can be used for sample preparation for scanning electron microscopy (SEM) and field emission-SEM (FESEM) analysis. If you are interested about electron microscopes and history of electron microscope, you can read more about them here.

For more information please click on the following link.

Glove box systems provide a protected environment for sensitive material, preventing any contact with air or humidity and unwanted interactions. DST2-TG high-vacuum coating system with glove box offers safe and clean substrate handling before or after a deposition process under inert gas atmosphere, and a highly controllable chamber environment, contributing to high purity thin layer deposition under high vacuum conditions.